Multi-spindle machining center

A machining center and multi-spindle technology, applied in metal processing, metal processing equipment, metal processing machinery parts, etc., can solve problems such as large overall space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

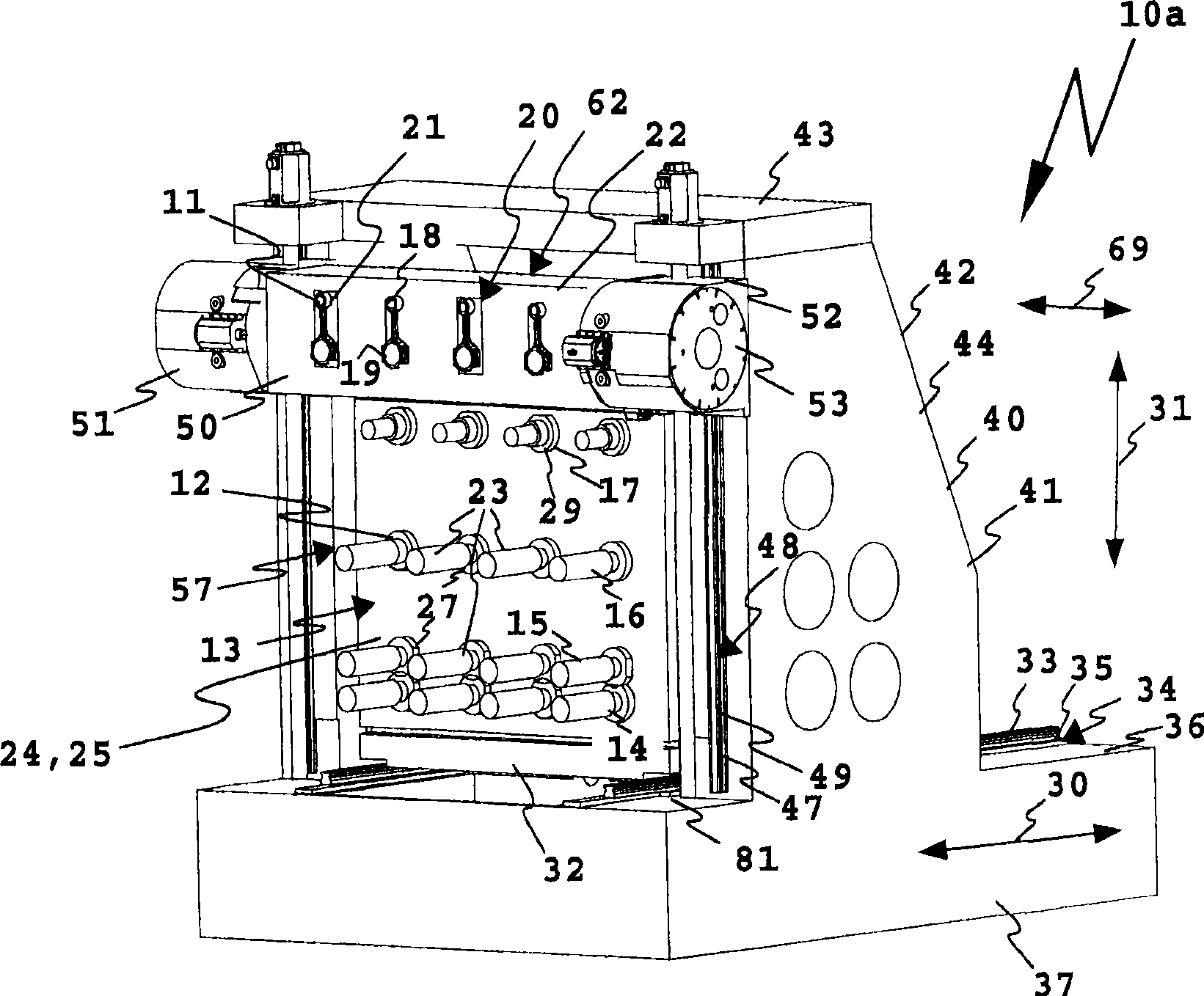

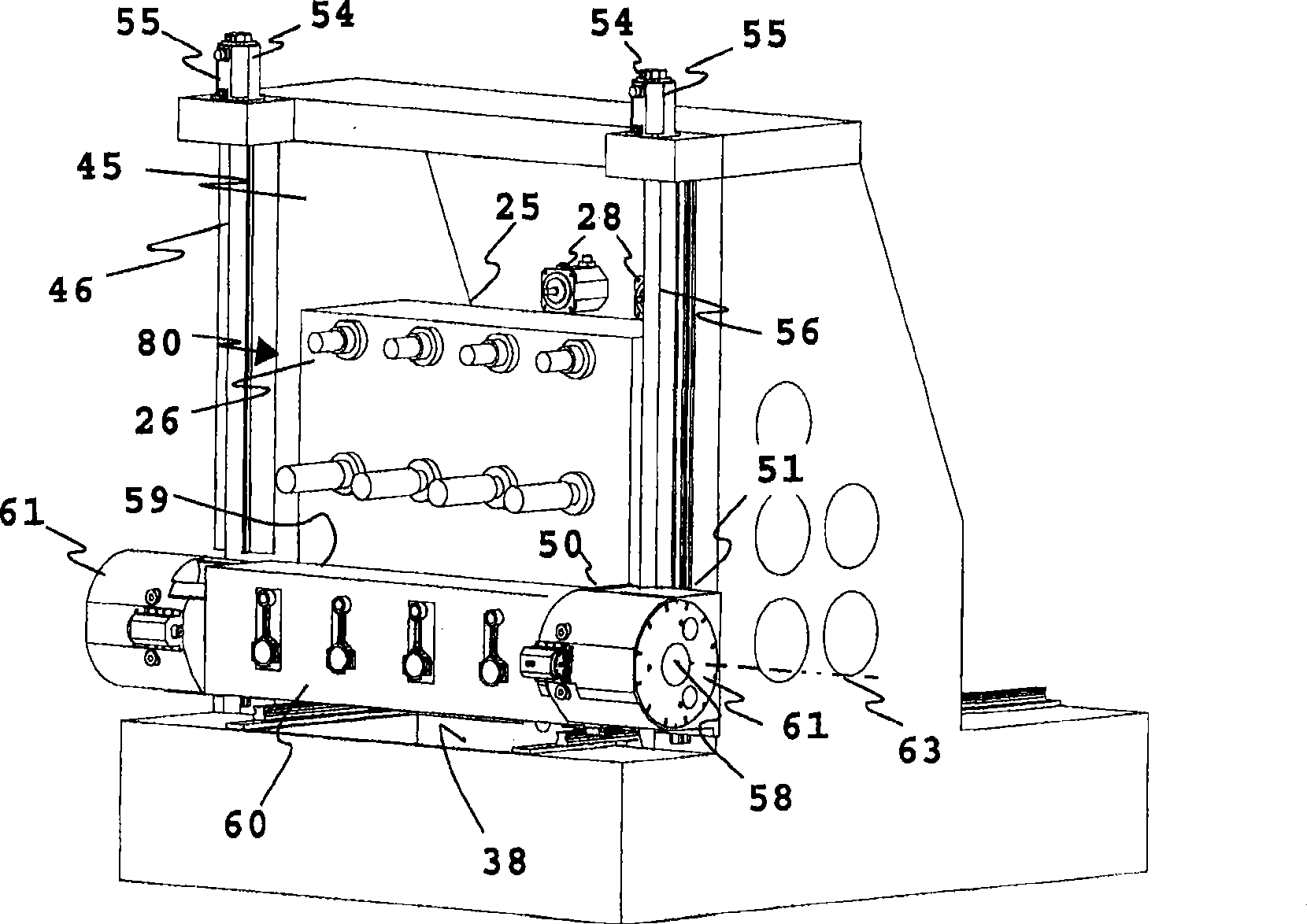

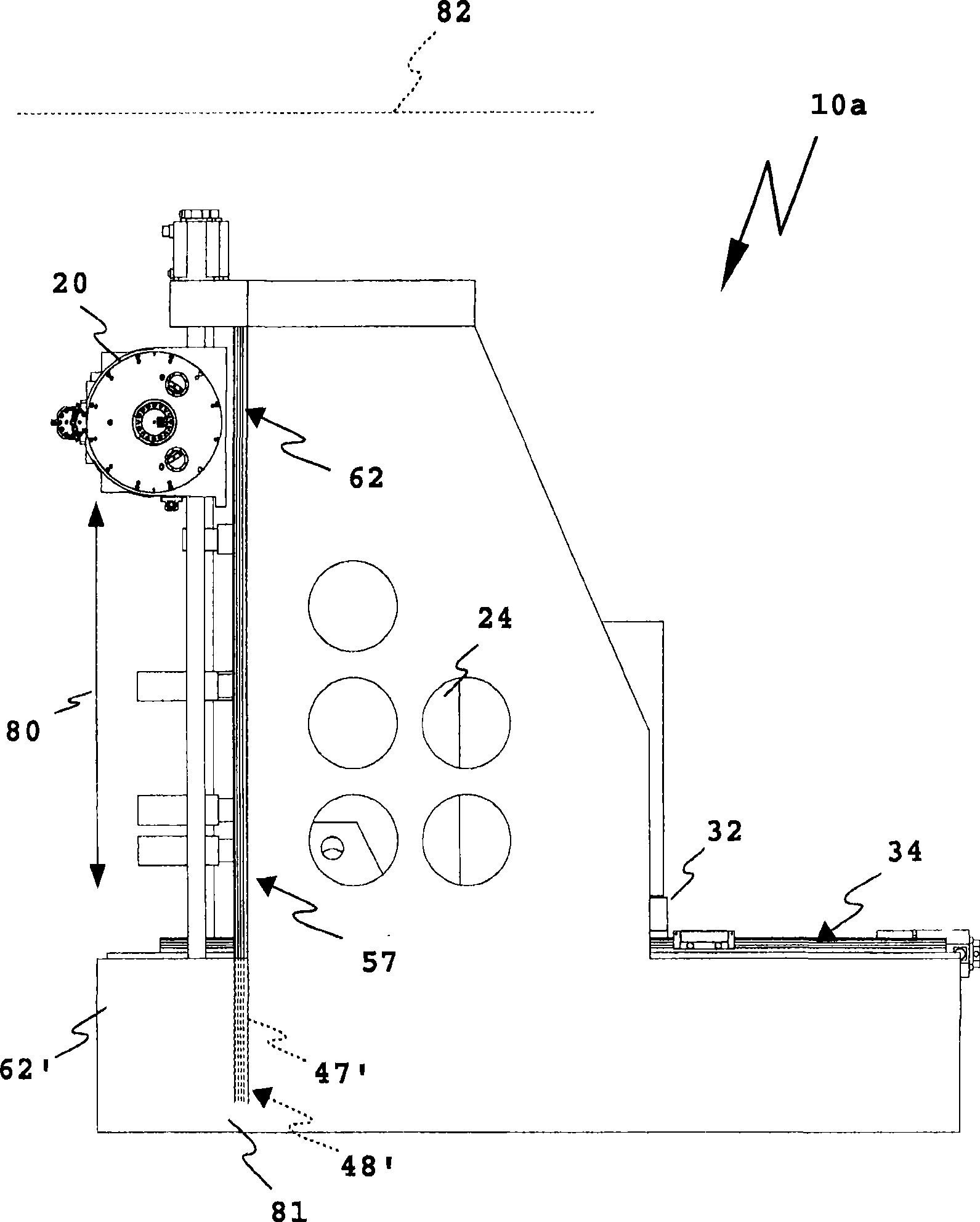

[0031] The multi-spindle machining center 10a is used for chip-forming machining of a workpiece 11, for example a connecting rod of an internal combustion engine. The multi-spindle machining center 10 a includes a spindle (or spindle) or a plurality of spindles 12 grouped together as a single spindle group 13 . Four spindles 12 are respectively arranged in each spindle row 14-17. Altogether, a total of four spindle rows 14-16, ie, twelve spindles 12, are shown. The spindles 12 in each spindle row 14 - 16 are in each case arranged horizontally in a straight line, however, arcuate row arrangements, row arrangements along zigzag lines etc. are also easily achievable. Furthermore, more or less than 12 spindles and more or less than 3 spindle rows are possible.

[0032] Chip forming tools 23 are mounted on the spindle 12, such as drilling and milling tools, lathe turning tools, and the like. A plurality of workpieces 11 can be machined simultaneously by means of the spindle 12 ....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com