Mechanism for preventing rubbing filtering packet of pulse bag-type dust remover

A bag filter and filter bag technology, applied in the field of flue gas purification, can solve the problems affecting the normal operation of the bag filter, increase the folding width of the filter bag, prolong the dust settlement time, etc., so as to improve the dust removal effect and work efficiency. , Improve the dust removal efficiency and dust removal effect, the effect of obvious energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

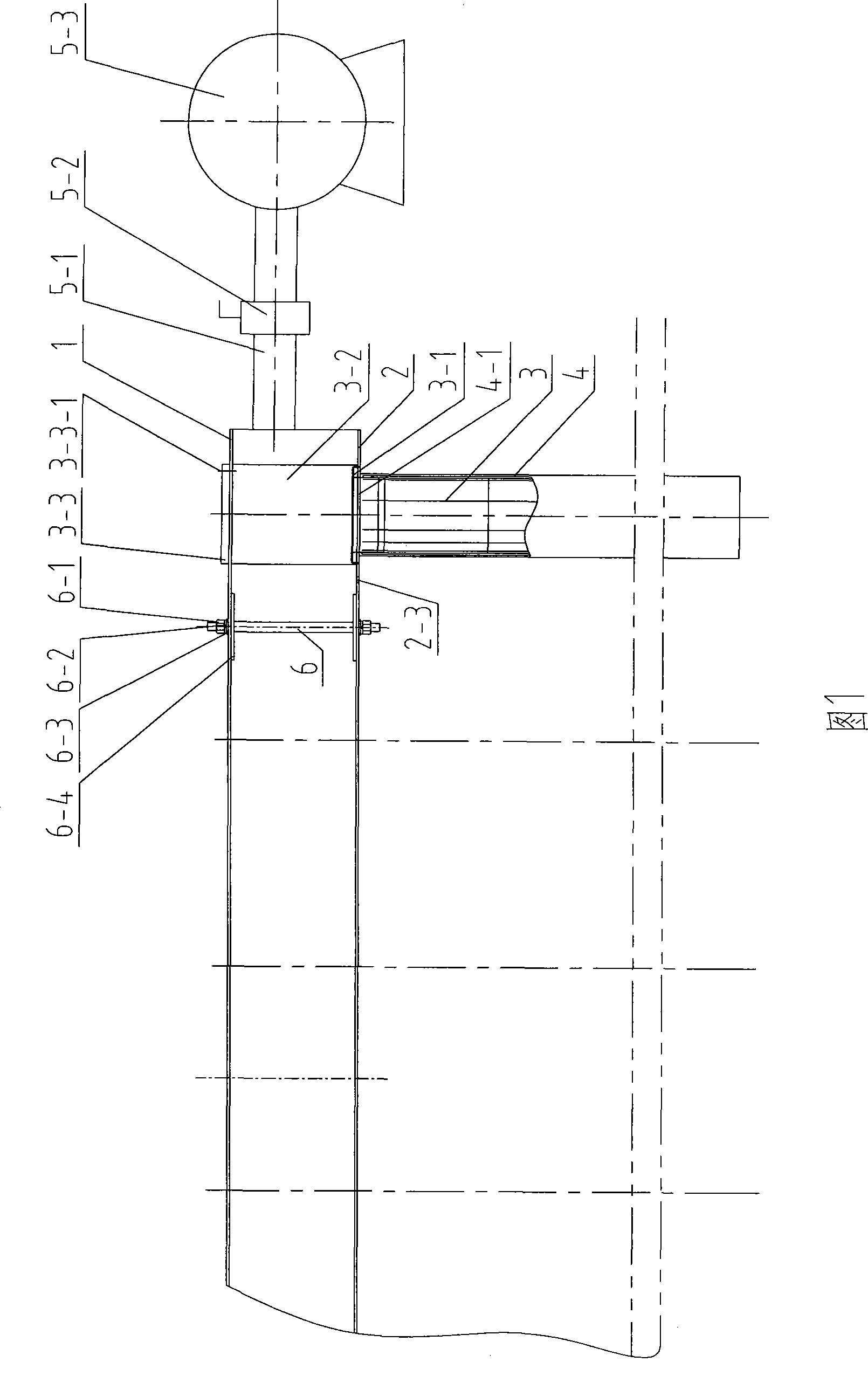

[0014] Below in conjunction with accompanying drawing, the present invention is described in further detail:

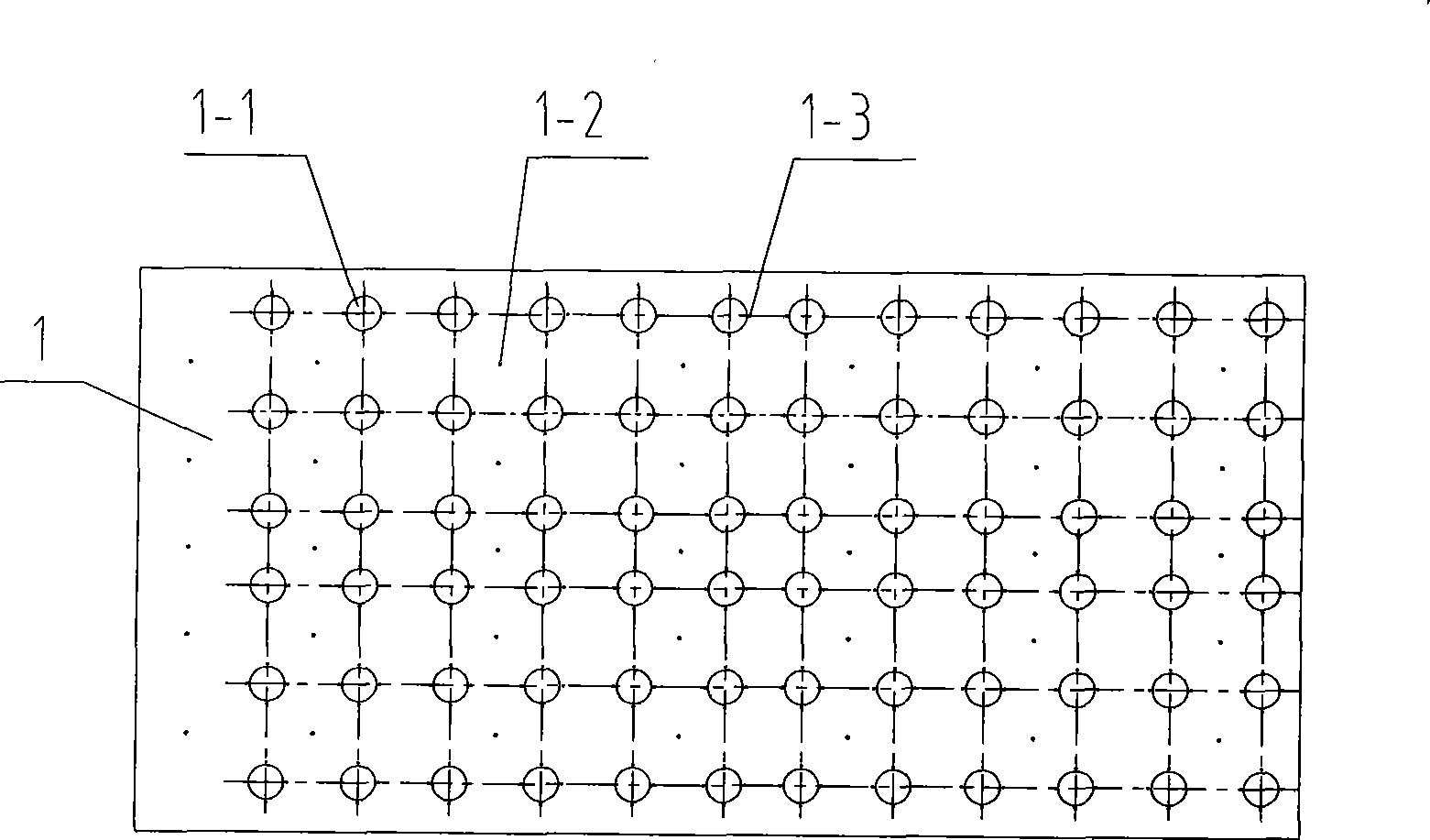

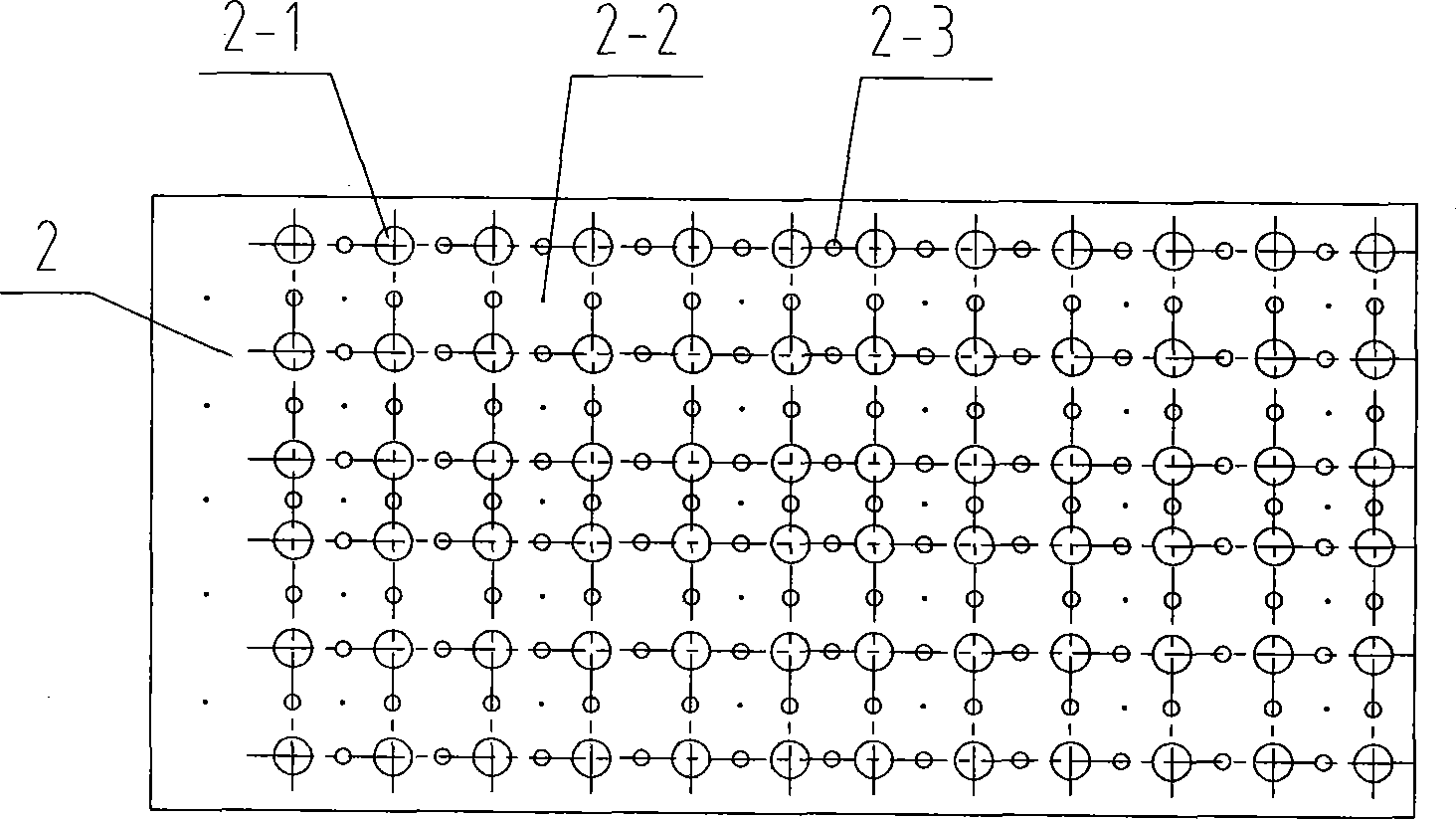

[0015] The present invention includes an upper flower board 1, a lower flower board 2, a connecting rod 6, a filter bag 4, a cage frame 3, a fan 5-3 and a blowing pipe 5-1; the upper flower board 1 and the lower flower board 2 are set up and down , on the upper and lower flower plates 1 and 2, there are several evenly distributed upper flower plate connecting holes 1-2 and lower flower plate connecting holes 2-2; both ends of the connecting rod 6 are provided with bosses and threads , and put them into the connecting hole 1-2 of the upper flower plate and the connecting hole 2-2 of the lower flower plate respectively, through the nut 6-1, spring washer 6-2, flat washer 6-3 and backing plate 6-4 The lower flower boards 1 and 2 are connected into a frame shape. On the upper and lower flower plates 1 and 2, there are correspondingly opened several evenly distributed upp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com