System level testing for substation automation systems

A substation automation and system-level technology, applied in the direction of circuit breaker testing, transmission system, digital transmission system, etc., can solve the problem of limited signal mode complexity in the test configuration range, and achieve the effect of alleviating the problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

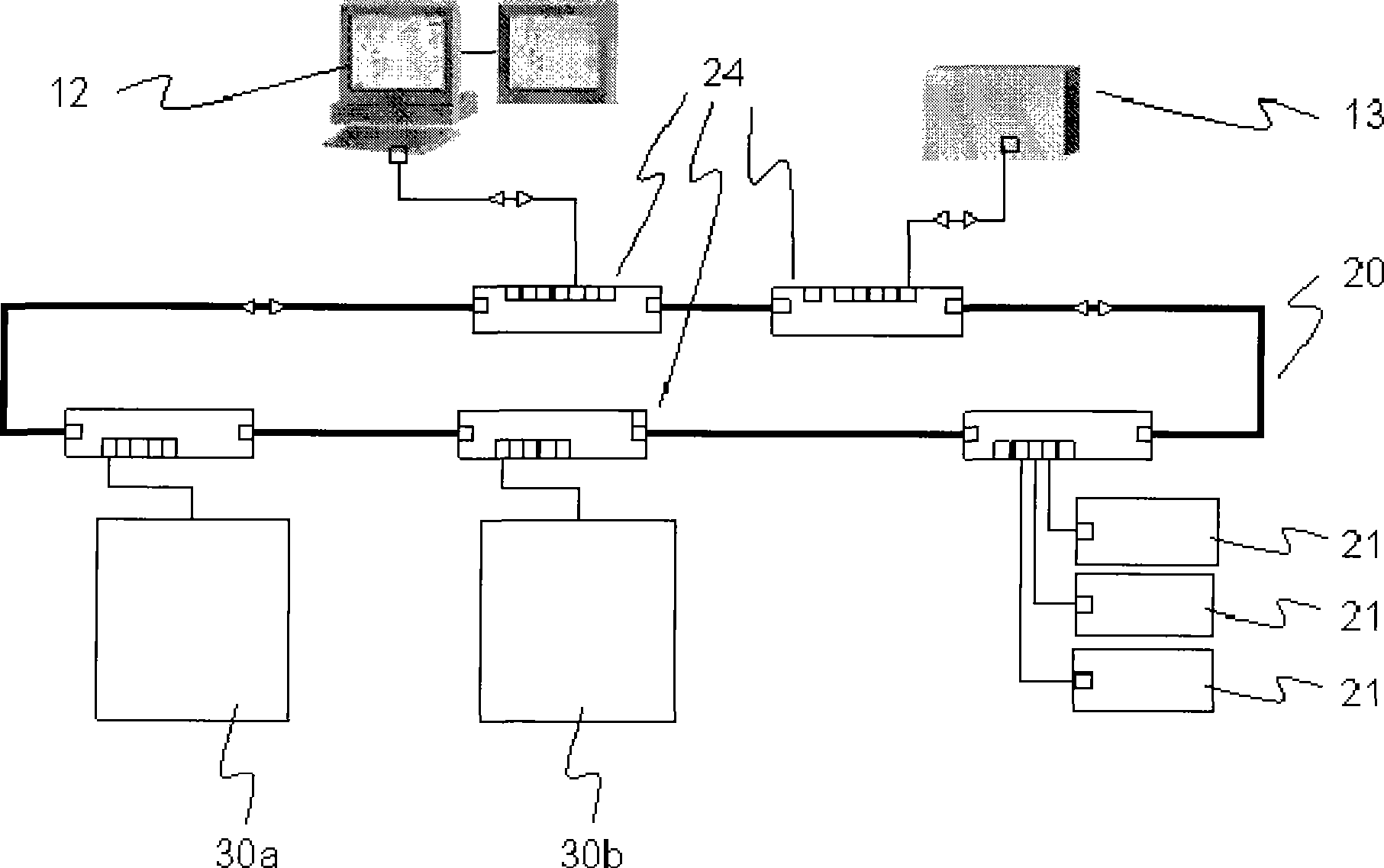

[0027] figure 1 A one-line diagram showing part or a fragment of an exemplary substation, and also includes some communication links and SA or secondary devices. For example, suppose the voltage level of the substation is 110kV. The model of a single-wire switchyard includes topological electrical connections between primary devices. The substation includes a double bus configuration with two bus bars 10, 10', each of which feeds two switch frames 11, 11' through circuit breakers QB1 to QB4. Each switch frame includes a circuit breaker QA1, an isolating switch QC1, and a grounding switch QE1. Corresponding parts of the substation automation system describe the communication network 20 and two IEDs 21, 22 in thick lines, both of which are the host logic nodes of the classification CSWI (switch control). Such as figure 1 As shown by the dotted line, each logical node is assigned to one of the above-mentioned circuit breakers QA1.

[0028] figure 2 The test environment or test e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com