Coordination control method for circulating fluidized bed generator set

A circulating fluidized bed, coordinated control technology, applied in the direction of controlling generators, control systems, electrical components, etc., can solve the problems of difficult control, large thermal inertia, large pure delay time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] Below in conjunction with the examples, the present invention is further described, the following examples are illustrative, not limiting, and the protection scope of the present invention cannot be limited by the following examples.

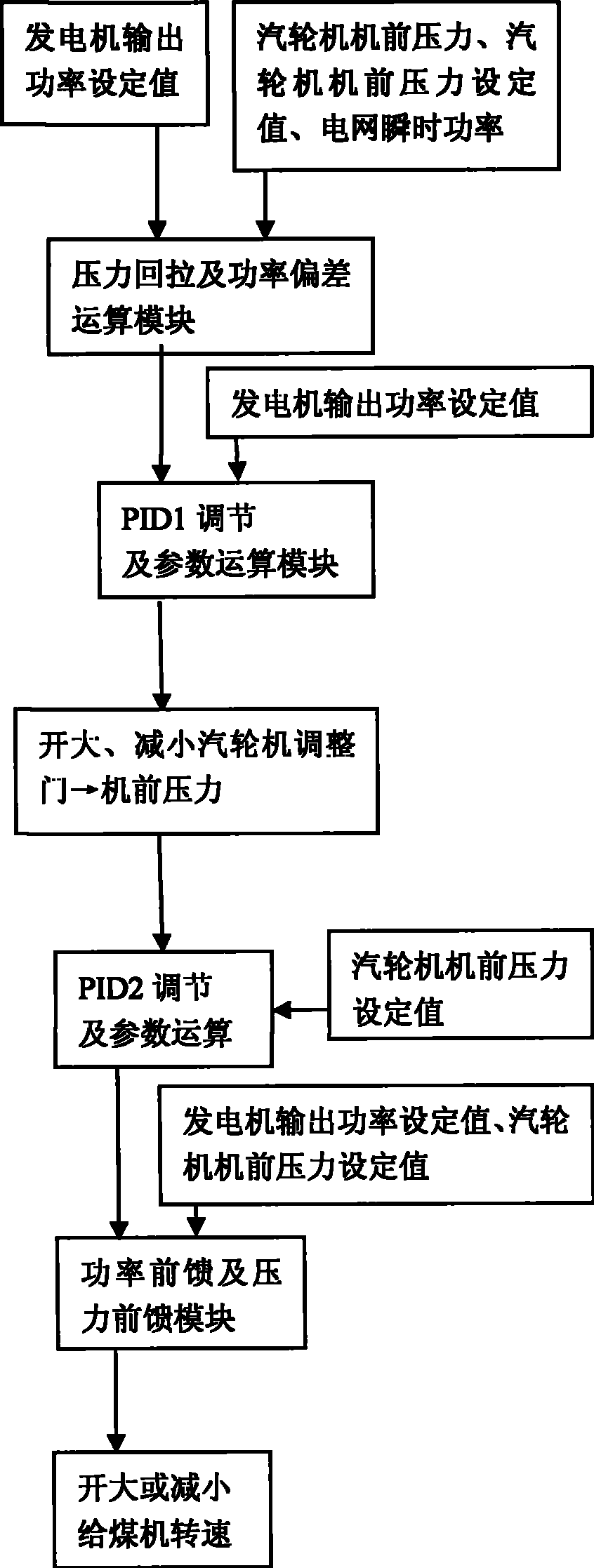

[0054] A coordinated control method for a circulating fluidized bed generator set, the steps of the coordinated control method are:

[0055] (1). Set the output power setting value of the generator and the pre-pressure setting value of the steam turbine, and the system switches from manual operation to automatic operation state;

[0056] (2). Detect and store the instantaneous power value of the grid and the pressure value before the steam turbine;

[0057] (3). Replace the set value of generator output power and the set value of the pre-machine pressure of the steam turbine with the stored instantaneous power value of the power grid and the pre-press value of the steam turbine respectively;

[0058] (4). The instantaneous power value of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com