Cutting tool assembly for peeling three bundle of parallel core wires and peeling machine using the same

A cutting tool assembly and stripping machine technology, which is applied in the installation of line/collector parts, electrical components, cables, etc., can solve problems such as low production efficiency, unpeeled wires, and shearing of conductive cores, and achieve improved stripping efficiency and operation The effect of convenience and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

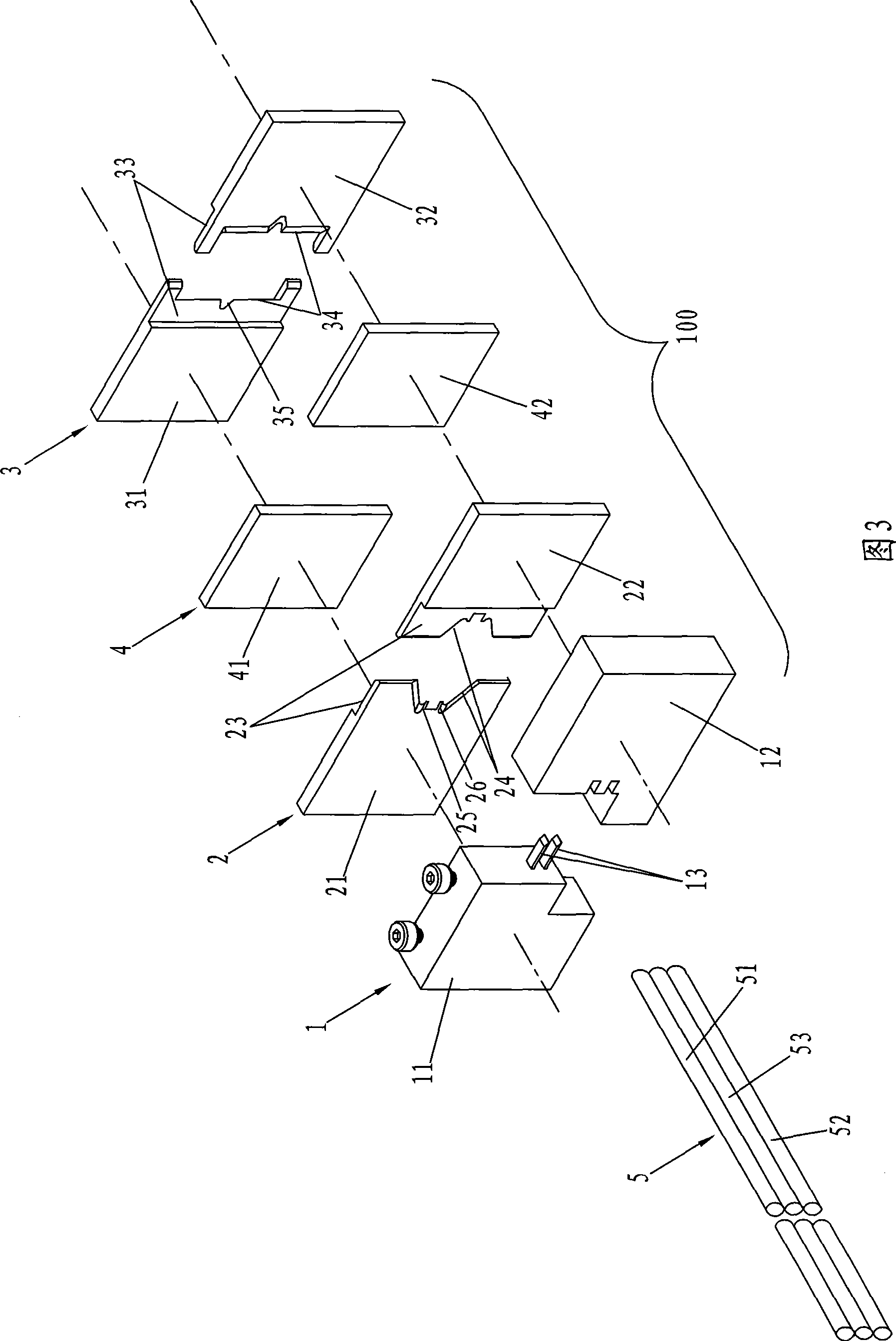

[0019] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

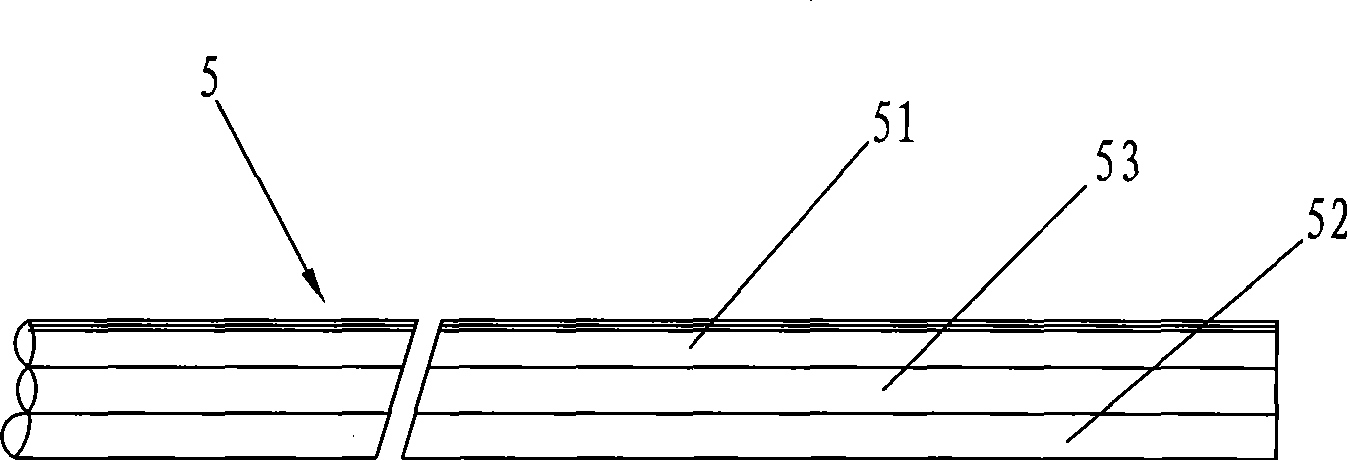

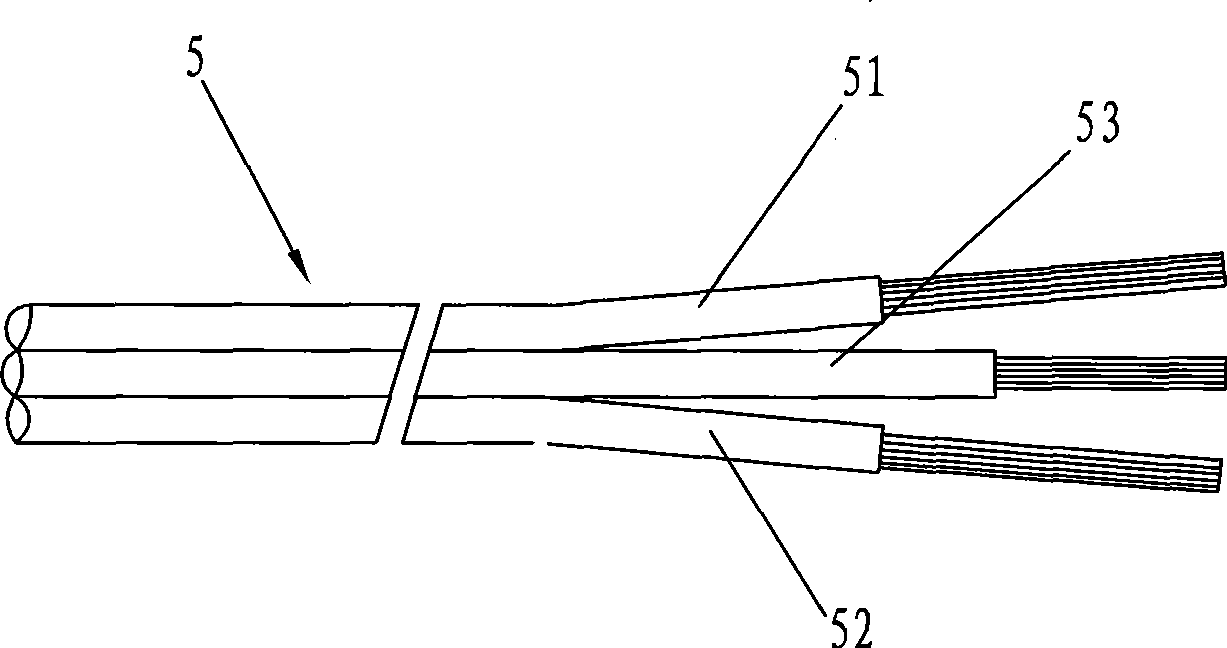

[0020] see Figure 1 to Figure 4 As shown, a cutter assembly 100 for stripping three bundles of parallel core wires is a tool for pre-cutting three bundles of parallel core wire sheaths. Cutting die 3 and spacer plate 4, wherein:

[0021] The bifurcated die 1 is used to divide the core wires 51, 52, 53 of the three bundles of parallel core wires 5; it includes a male die 11 and a female die 12. The mold surface is provided with two upper and lower parallel bifurcated cutters 13, which are beneficial to the bifurcated cutters to split the three bundles of parallel core wires in advance.

[0022] The first cutting die 2 is used for correspondingly cutting the sheaths of the side core wires 51 and 52 of the three bundles of parallel core wires 5; wherein the first cutting die 2 is composed of a first die die 21 and a second die die 22 The clamp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com