Magnetic collection feedback type optical fiber current sensor

A fiber-optic current and sensor technology, applied in the field of sensing, can solve the problems that hinder the popularization and application of MOCT, the long-term stability is difficult to be guaranteed, and the magnetic field of the permanent magnet is not stable enough, so as to achieve a large linear measurement range, convenient signal demodulation, and no The effect of easy magnetic saturation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

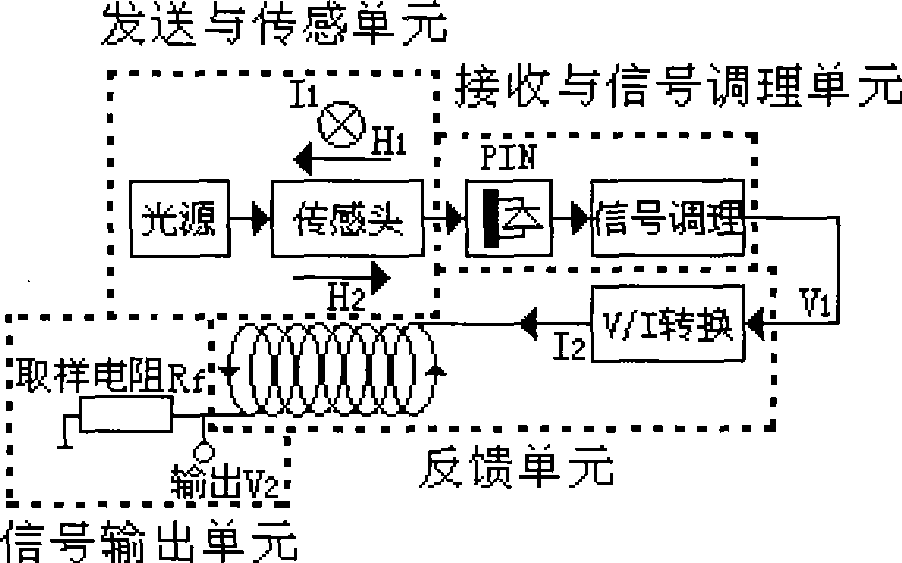

Method used

Image

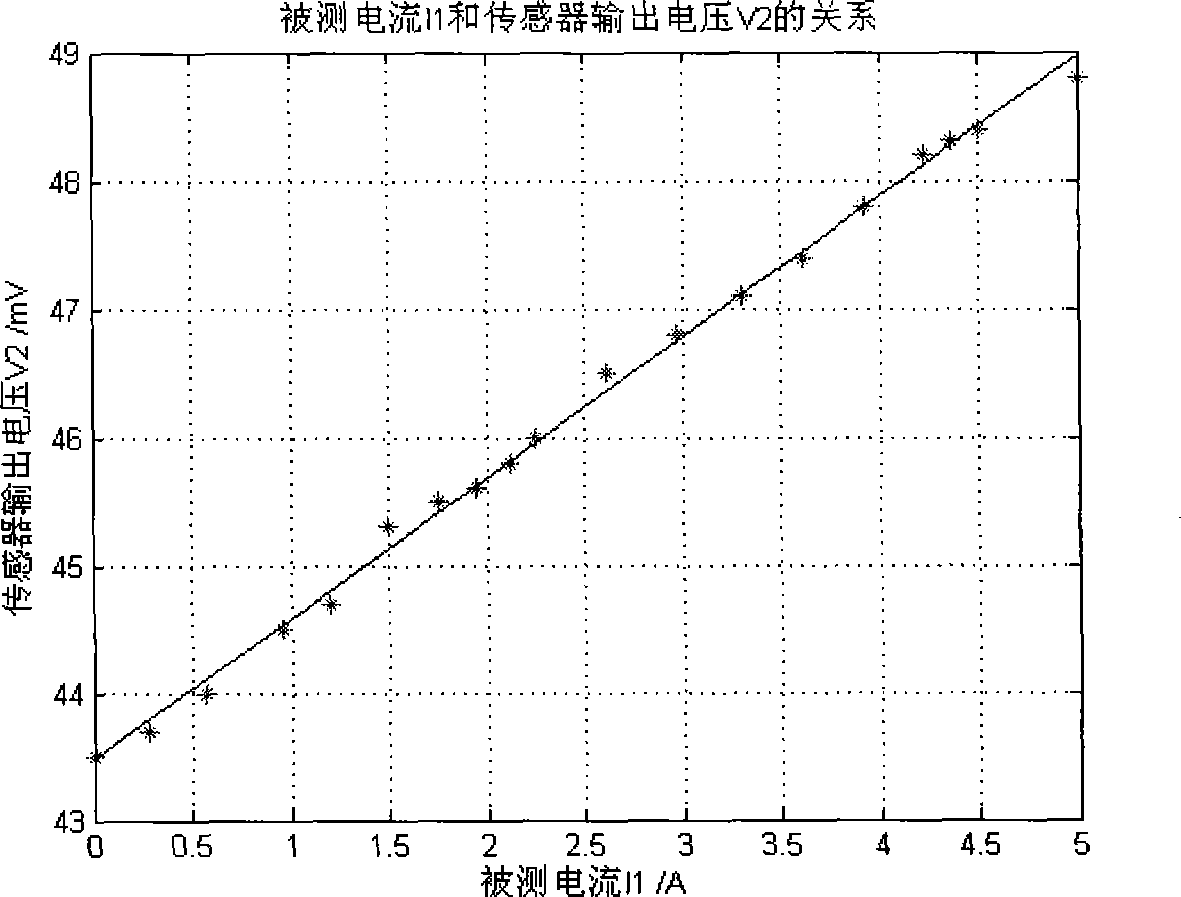

Examples

Embodiment 1

[0027] Follow the steps below to make a magnetic feedback fiber optic current sensor:

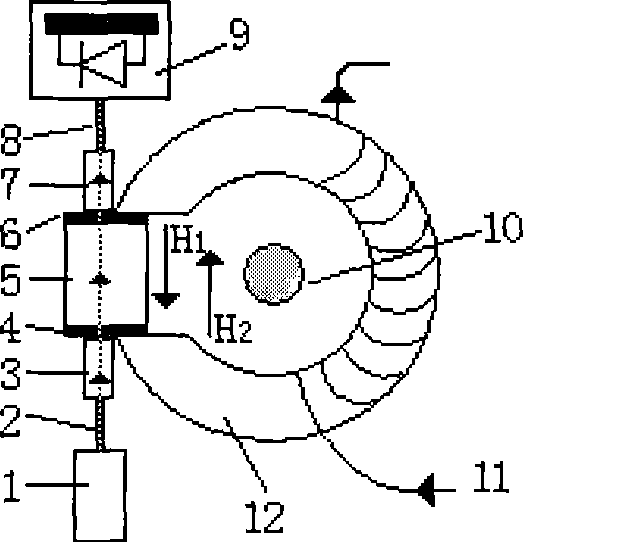

[0028] (1) Glue the optical fiber, self-focusing lens, polarizer, magneto-optical glass and analyzer with glue, specifically: fix the optical fiber 2 on one end of the self-focusing lens 3, and couple the other end of the self-focusing lens 3 to the starting point Polarizer 4; the other side of the polarizer 4 with optical fiber is pasted on one of the sides perpendicular to the axis of the magneto-optical glass 5; the other side is perpendicular to the axis of the magneto-optical glass 5 and an analyzer is bonded The other side of the analyzer 6 is connected with the second self-focusing lens 7; the output optical fiber 8 is fixed on the output end of the second self-focusing lens 7;

[0029] (2) Wind the feedback coil 11 on the magnetic collecting ring 12 with enameled wire

[0030] (3) The magnetic collecting ring 12 around the feedback coil 11 is placed on one side of the magneto-optic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com