Method and apparatus for fermentation production of sludge gas with mixed stalk raw material

A technology for mixing raw materials and producing biogas, which is applied in the methods of biological material sampling, fermentation, and biochemical cleaning devices, etc., can solve the problem of winter production of biogas in alpine regions, single pretreatment method, and low comprehensive utilization rate. To achieve sustainable development, avoid secondary pollution, and reduce construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

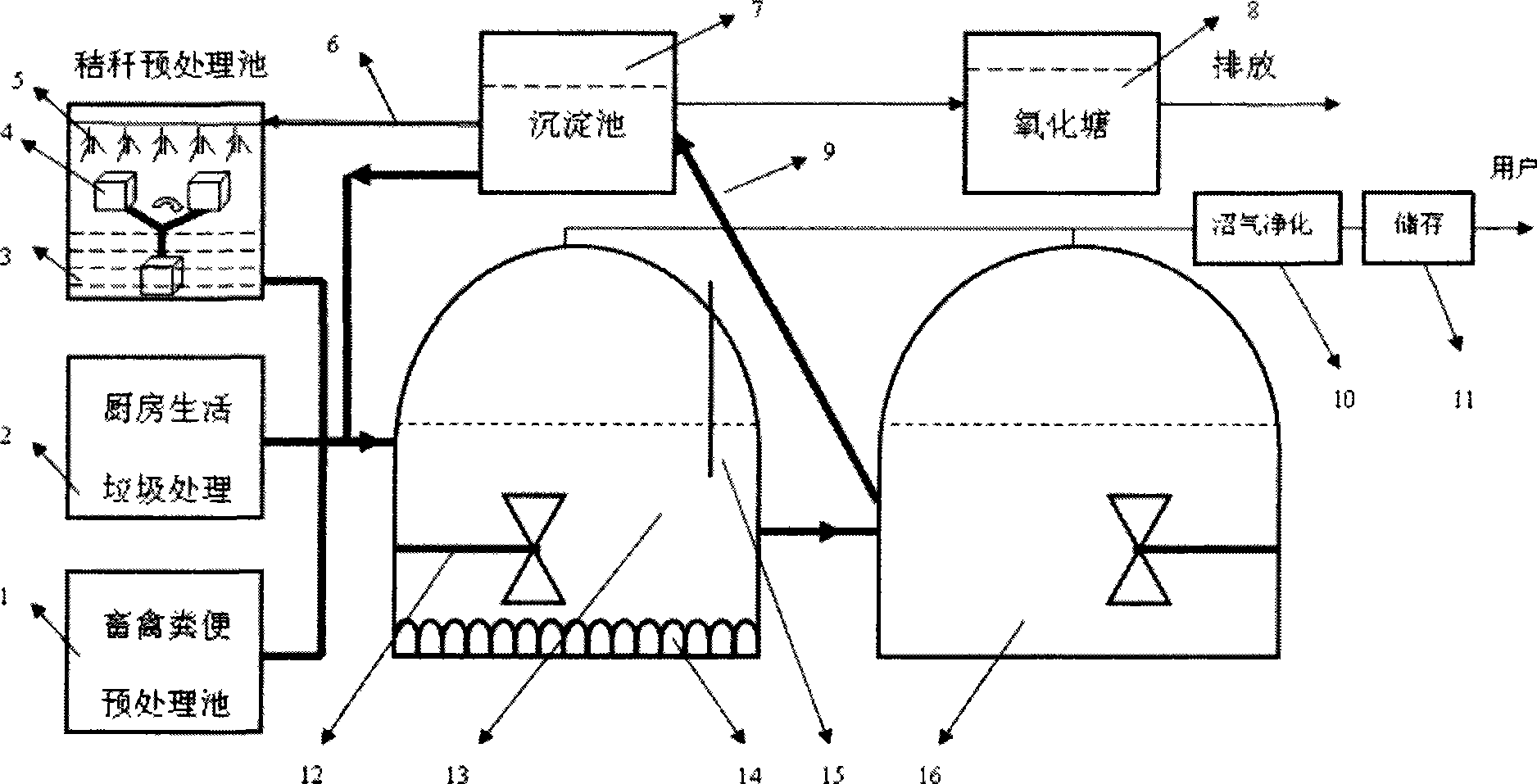

[0008] Embodiment 1: As shown in the figure, it is a method and device for producing biogas by fermenting straw mixed raw materials. The present invention has designed the pretreatment of three kinds of raw materials, is 1. livestock and poultry feces pretreatment pond, 2. kitchen life garbage pretreatment pond, 3. straw pretreatment pond, wherein straw pretreatment pond 3 is a closed box, the bottom has Heating device, inside there are 4. Rotating box with micropores and 5. Biogas slurry spray head, three pretreatment tanks are connected with 13. Anaerobic fermentation main tank through transmission pipeline with sludge pump, anaerobic fermentation main tank 12. Stirring device, 14. Circulating heating coil and 15. Temperature probe are installed in the pool 13; the anaerobic fermentation main pool 13 is connected with the 16. anaerobic fermentation auxiliary pool through a transmission pipeline with a sludge pump, Pool 16 is connected to 7. sedimentation tank through 9. tran...

specific Embodiment approach 2

[0009] As shown in the figure, in this embodiment, on the basis of Embodiment 1, the straw pretreatment pool 3 is a closed box, heat preservation measures are taken, the bottom is heated, and the temperature is controlled at medium temperature or high temperature, so that the efficiency of straw pretreatment is improved.

specific Embodiment approach 3

[0010] As shown in the figure, this embodiment adopts heat preservation measures for all three pretreatment tanks on the basis of specific embodiment 1. The bottom is heated, and the temperature is controlled at medium temperature or high temperature, so that the pretreatment efficiency of all feed liquids is improved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com