Paster

A patch and attachment technology, applied in the field of materials, can solve the problems of waste, single use range, etc., and achieve the effect of wide range of use and simple process production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

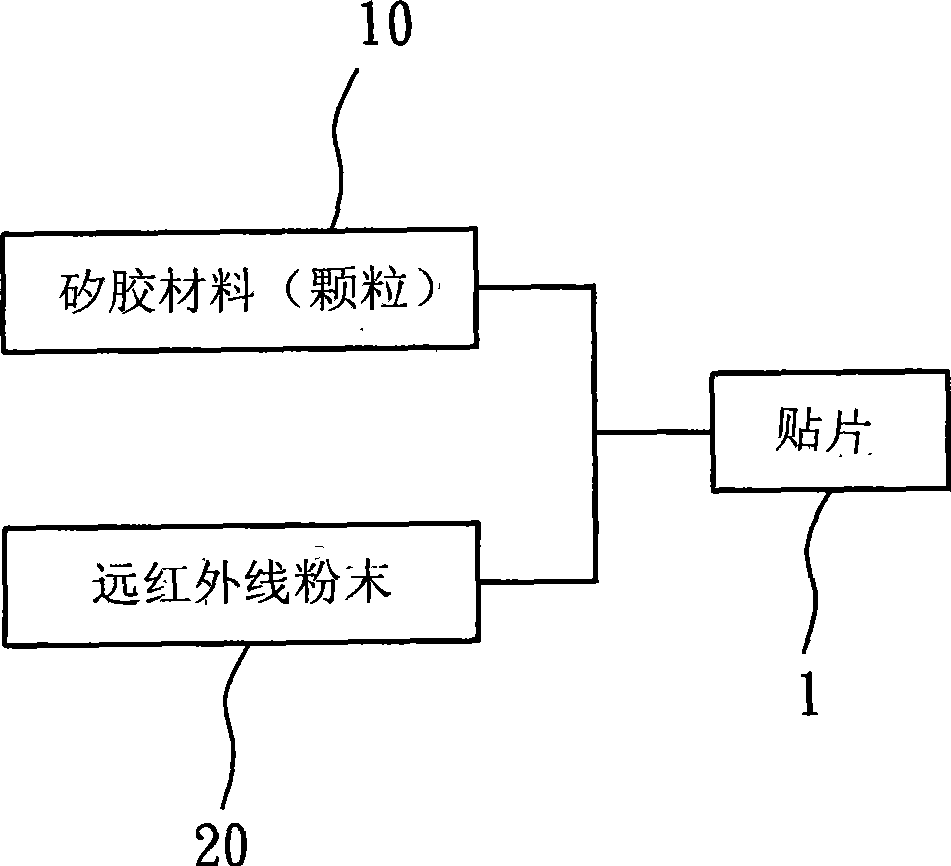

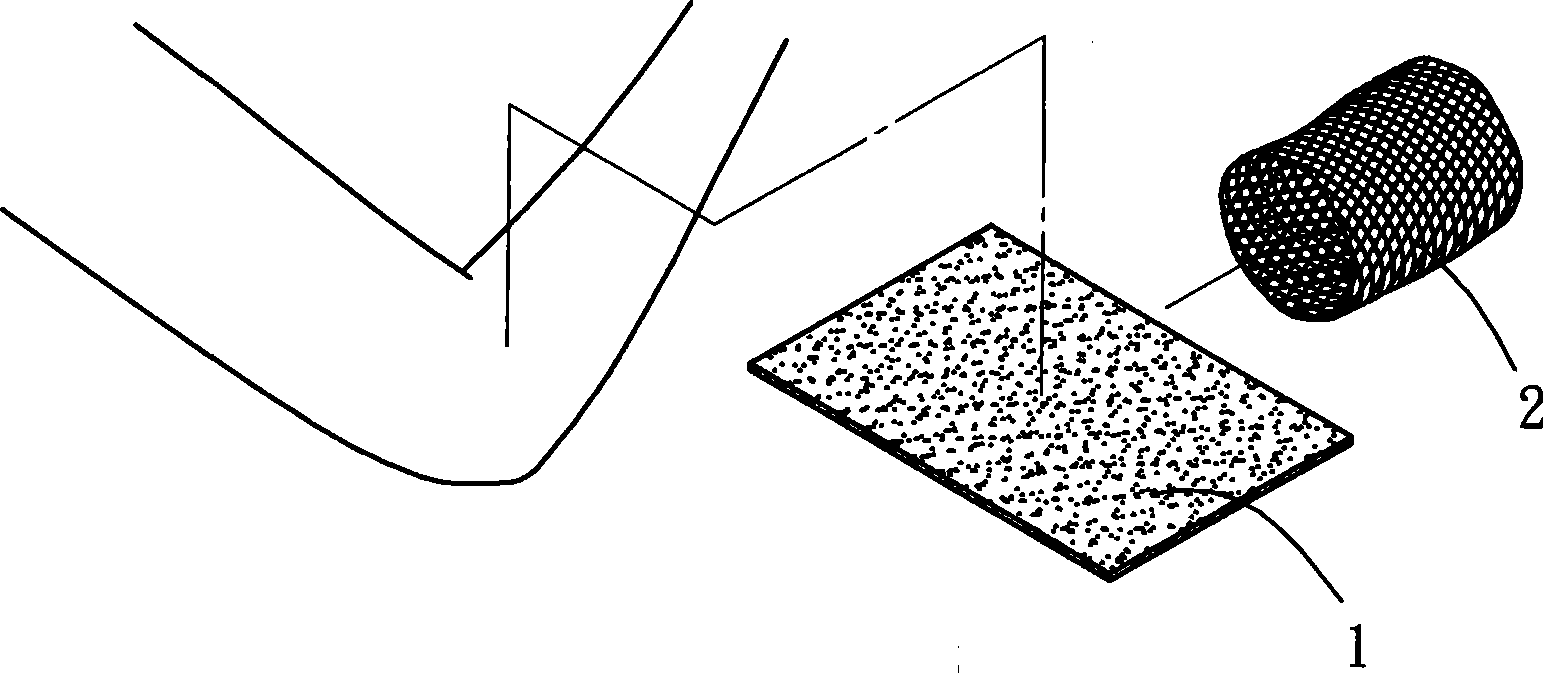

[0027] A patch of the present invention, please refer to figure 1 As shown in 2, the patch 1 is made of silicone material 10 (silicone X-500A485g, silicone X-500B5g) and far-infrared powder 20 (powder particle size is 300 mesh 500g) and silicone oil (10g) After stirring and mixing, it is formed into a shape, as shown in Figure 2.

[0028] The specific manufacturing steps are as follows:

[0029] (1) Mix 485 grams of silicone material X-500A with 500 grams of far-infrared powder of 300 meshes, and add 10 grams of silicone oil that can play a role of intermediate mixing and bridging, so that the far-infrared powder and silicone are closely integrated;

[0030] (2) Put it into a vacuum pressure cooker to make the powder and the inter-molecular gap of silicone gel to be mutually dissolved and combined;

[0031] (3) The two materials of far-infrared powder and silicone are more closely integrated by the strong grinding of the roller;

[0032] (4) Add 5 grams of X-500B bridging agent t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com