Reinforcing method for ultra-thin lithium alumina silicate glass

A technology of aluminosilicate glass and ultra-thin glass, which is applied in glass tempering, glass production, glass manufacturing equipment, etc., can solve the problem that ultra-thin lithium aluminosilicate glass cannot be used for industrialization enhancement, the flexural strength is not easy to control, and the problems such as low yield, to achieve the effect of good finish, high yield and improved service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

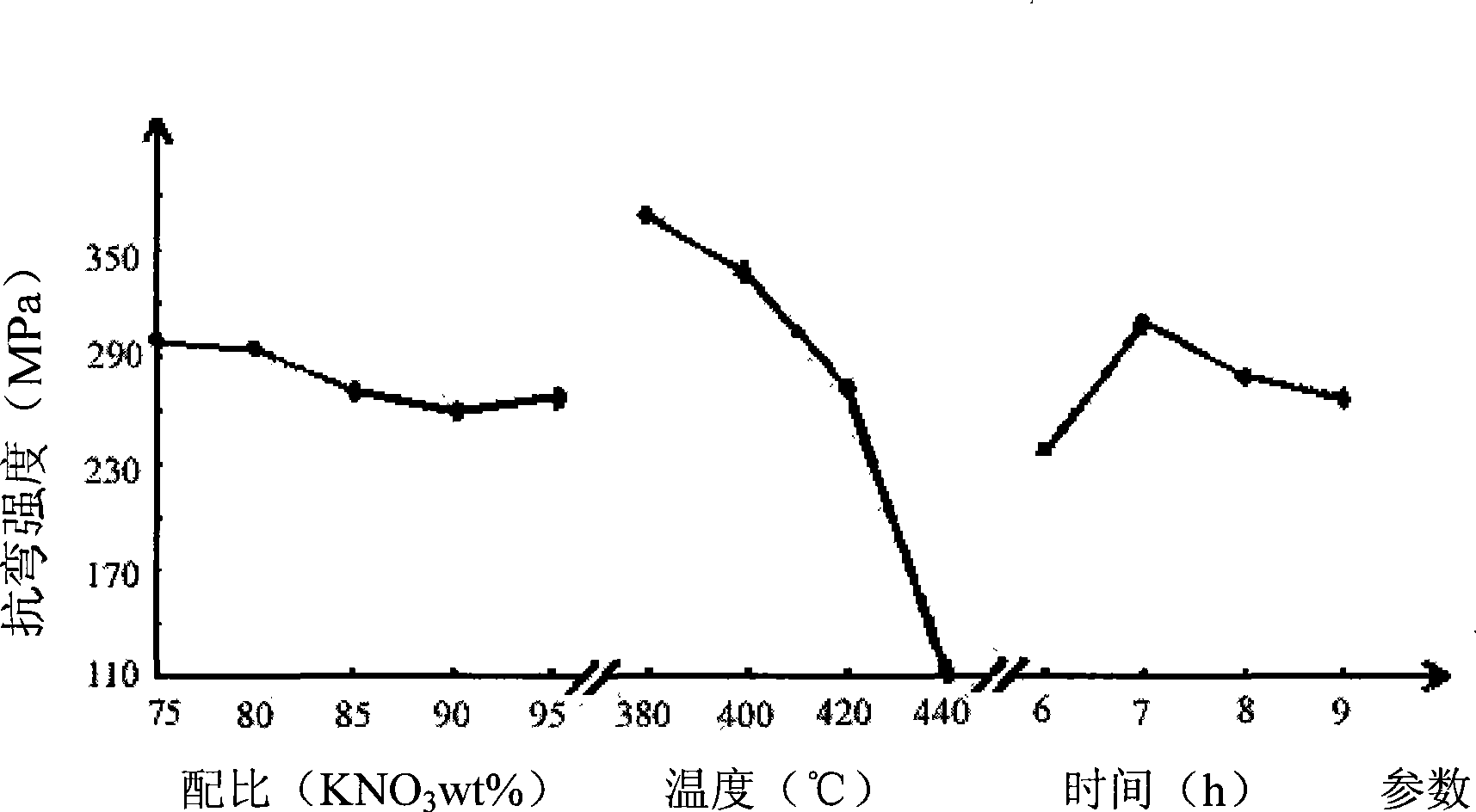

Embodiment 1

[0027] According to 85wt.% KNO 3 and 15wt.% NaNO 3Proportionally prepare 50 kg of molten salt, and add 0.15wt% of KOH and Al in addition 2 o 3 , melted in a well-type resistance furnace, and clarified for 30h. Put the ultra-thin glass sample (120mm×40mm×0.1mm) into the temperature-resistant tooling, preheat it in the resistance furnace for 15 minutes, and then immerse it in the molten mixed molten salt for strengthening treatment. The strengthening temperature is controlled at 380°C. The time is 7h. After taking it out from the molten salt, clean the sample: first with deionized water, then with alcohol and dry.

[0028] Tests on treated glass:

[0029] 1. Surface observation: the ultra-thin glass has a good surface finish, no deformation, and a high yield.

[0030] 2. Bending strength test: use the three-point bending strength test method (reference standard JC / T676-1997 "Test method for bending strength of glass materials"). The results showed that the bending strengt...

Embodiment 2

[0035] According to 95wt.% KNO 3 and 5wt.% NaNO 3 Proportional preparation of 50 kg of molten salt, plus 0.1wt.% of KOH and A1 2 o 3 , melted in a well-type resistance furnace, and clarified for 40h. Put the ultra-thin glass sample (120mm×50mm×0.1mm) into the temperature-resistant tooling, preheat it in the resistance furnace for 15 minutes, and then immerse it in the molten mixed molten salt for strengthening treatment. The strengthening temperature is controlled at 400°C, and the time for 8h. Finally, the sample was cleaned, dried and tested in the same manner as in Example 1.

[0036] Results: After strengthening, the surface finish of the ultra-thin glass is good, no deformation occurs, and the yield is high; the bending strength of the ultra-thin glass sample before treatment is 68MPa, and the bending strength after treatment reaches 356MPa.

Embodiment 3

[0038] By 75wt% KNO 3 and 25wt% NaNO 3 Proportional preparation of 50 kg of molten salt, plus 0.1wt.% of KOH and Al 2 o 3 , melted in a well-type resistance furnace, and clarified for 30h. Put the ultra-thin glass sample (80mm×40mm×0.09mm) into the temperature-resistant tooling, preheat it in the resistance furnace for 20 minutes, and then immerse it in the molten mixed molten salt for strengthening treatment. The strengthening temperature is controlled at 420°C, and the time for 6h. Finally, the sample was cleaned, dried and tested in the same manner as in Example 1.

[0039] Results: After strengthening, the ultra-thin glass has a good surface finish, no deformation, and a high yield. The bending strength of the ultra-thin glass sample in this example is 64MPa before treatment, and the bending strength reaches 380MPa after treatment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com