Nutrition reinforced varek sauce and method of producing the same

A technology for nutritional enhancement and seaweed, which is applied in the field of nutritionally enhanced seaweed soy sauce and its preparation, can solve the problems of small addition amount, poor nutritional enhancement effect, potential safety hazards, etc., and achieves the effects of stable quality, flexible process and easy absorption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

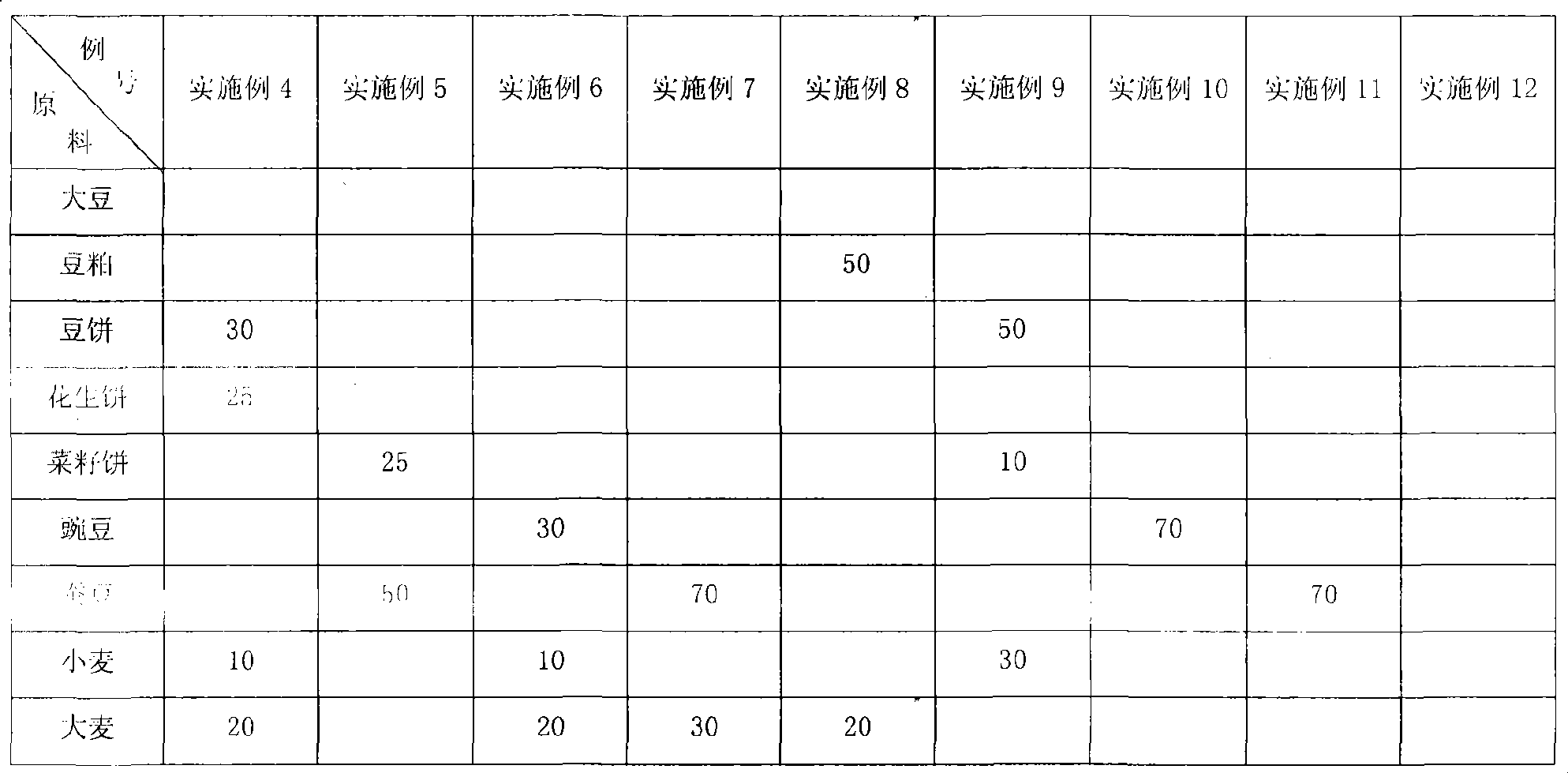

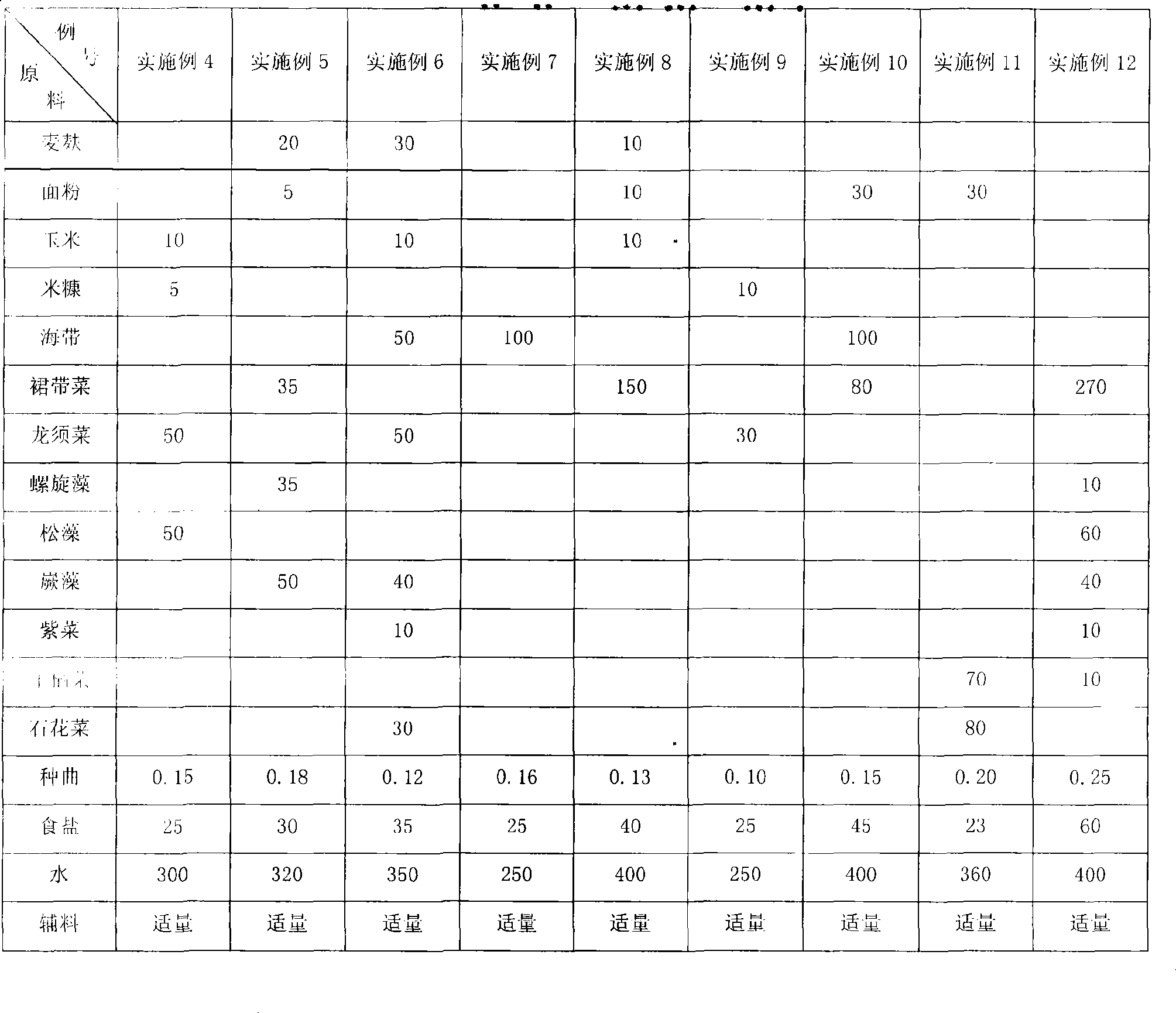

Examples

Embodiment 1

[0057] a. Material preparation: Weigh 55 kg of clean defatted soybeans, soak them; 45 kg of wheat bran, moisten with water; wash and chop to about 3.5 cm 2 100 kilograms of fresh sea-tangle three kinds of raw materials are mixed evenly, wait to cook; Take 20 kilograms of table salts and be mixed with the aqueous solution of 10% concentration for use; Total water consumption 380 kilograms;

[0058] b. Steaming material: the mixed raw material is steamed for 20-50 minutes under the pressure of 0.1-0.2Mpa, and then cooled;

[0059] c. Koji making by inoculation;

[0060] d. Deriving and mixing koji: Weigh 0.05 kg of koji, disperse it in an appropriate amount of salt water, mix it with the boiled and cooled raw materials, and put it into the fermentation tank;

[0061] e. Fermentation: ferment for 20-60 days at a temperature of 28°C-40°C;

[0062] f. Soaking and oil extraction;

[0063] g. Preparation and sterilization;

[0064] h. Inspection, packaging, storage;

[0065] i. ...

Embodiment 2

[0067] According to the operation steps of Example 1, 75 kg of clean soybeans were weighed and soaked; 25 kg of flour, washed and chopped to about 3-5 cm 2 150 kilograms of undaria pinnatifida are mixed evenly, wait to cook; Take 25 kilograms of table salts and be mixed with 10% aqueous solution standby; Seed koji consumption 0.1 kilogram, water consumption 400 kilograms. Then according to the steps of Example 1, cooking; inoculation, koji making; koji production, mixing koji; fermentation; oil extraction by immersion once, preparation, sterilization, inspection, packaging, storage; By adding auxiliary materials and blending, the nutrient-enhanced seaweed soybean paste can be successively produced, and after passing the inspection, it is packaged and put into storage.

Embodiment 3

[0068] Embodiment 3. According to the operation steps of embodiment 1, take and wash and chop to about 3-5cm 2400 kg of kelp, fermented separately; 0.25 kg of seed koji, 60 kg of salt, and 300 kg of water. Prepare pure edible seaweed soy sauce. The sauce residue after soy sauce is extracted, inspected, packaged, and used as a by-product of food additives.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com