Speed response type damper and shock-absorbing damper device

A damper and speed technology, applied in the direction of shock absorbers, shock absorbers, springs/shock absorbers, etc., can solve problems such as working fluid bubbles, damage to left and right balance, piston rod tilting, etc., to eliminate sudden changes in repulsive force , Improve the rectification effect, eliminate the effect of the inclination of the piston rod

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In the present invention, an orifice is provided on the top end side of the piston, and air rupture occurs in the annular portion of the piston, so the cracking sound can be reduced, and the inner circumference of the slider that can adjust the amount of fluid passing through the piston has a plurality of rectifying protrusions. Therefore, sudden changes in repulsive force and tilting of the piston rod can be prevented during high-speed operation.

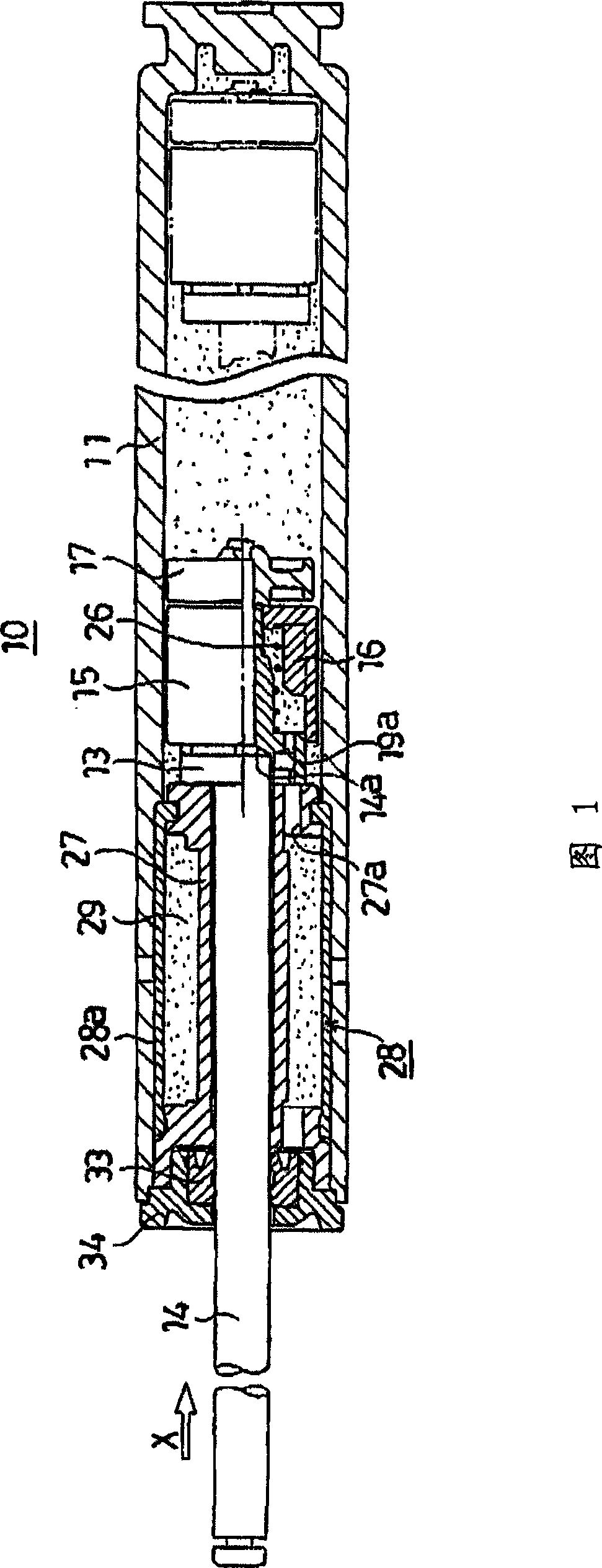

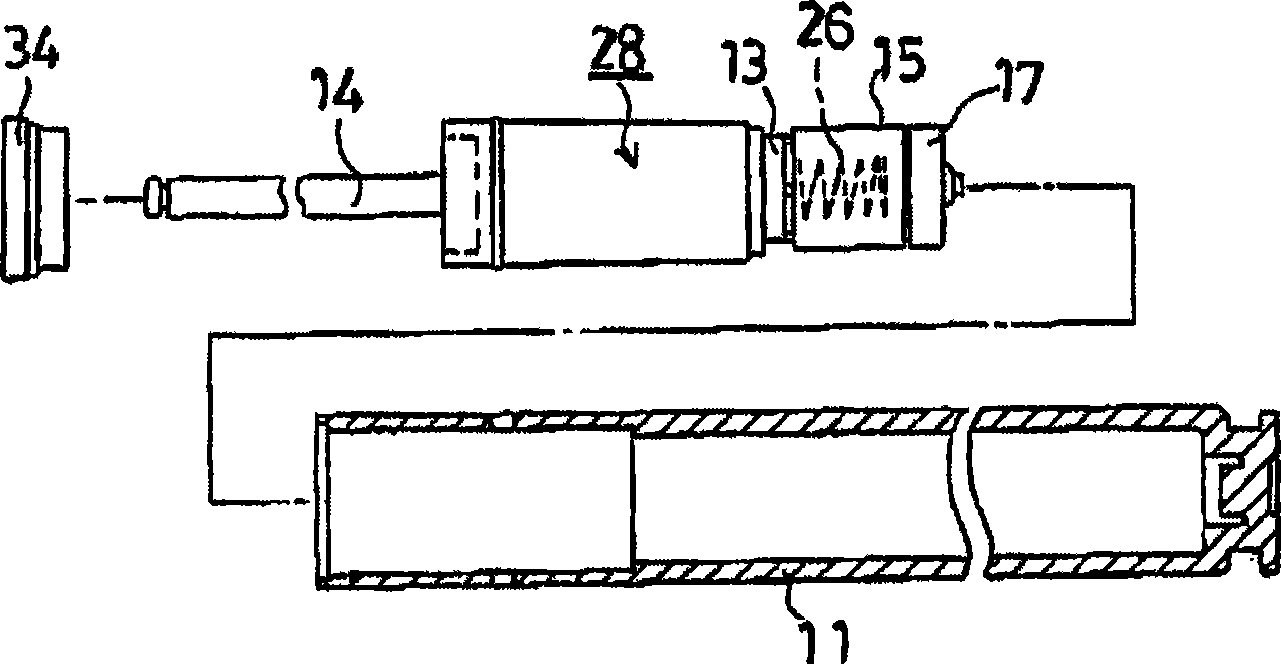

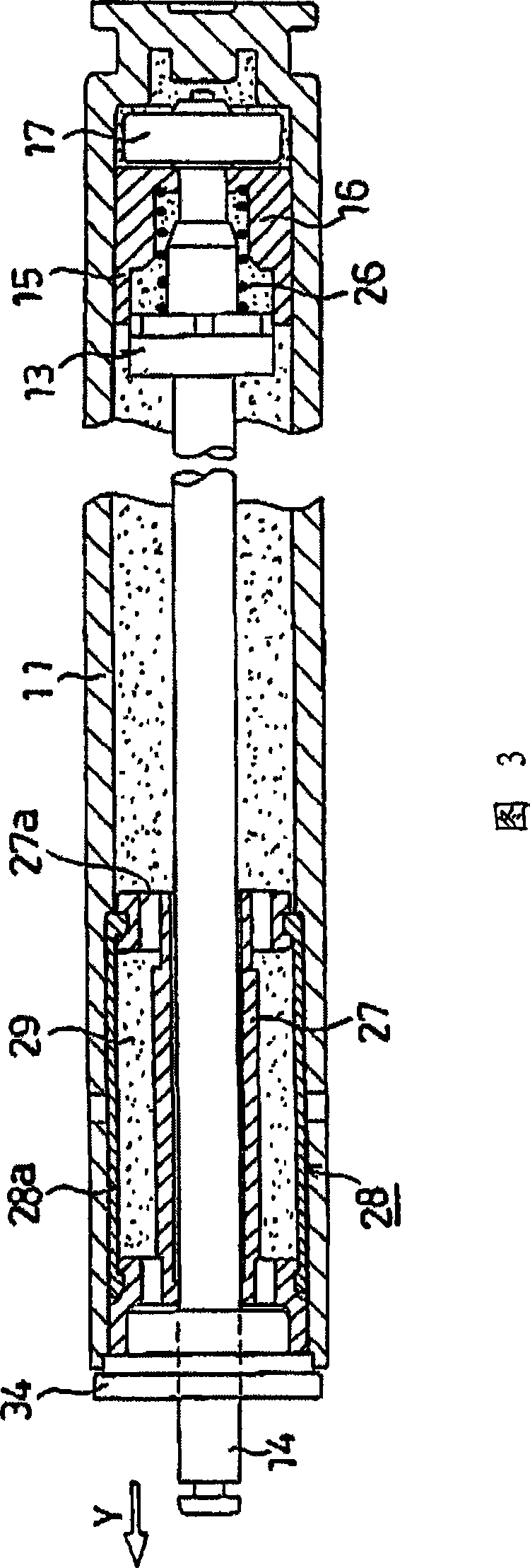

[0037] Hereinafter, the present invention will be described in detail based on the drawings showing an embodiment. FIG. 1 is a cross-sectional view showing the overall structure of a speed-responsive damper according to the present invention, figure 2 FIG. 3 is an exploded view showing an example of the speed responsive damper of the present invention, and FIG. 3 is a cross-sectional view showing an operating state of the speed responsive damper of the present invention. Here, the speed-responsive damper 10 has a cylinder ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com