Using lipid to improve lignocellulosic fibre bonding and dimensional performance

A technology of lignocellulose and fiber, applied in applications, household components, household appliances, etc., can solve the problems of increasing the cost of final products, expensive release agents and release paper, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

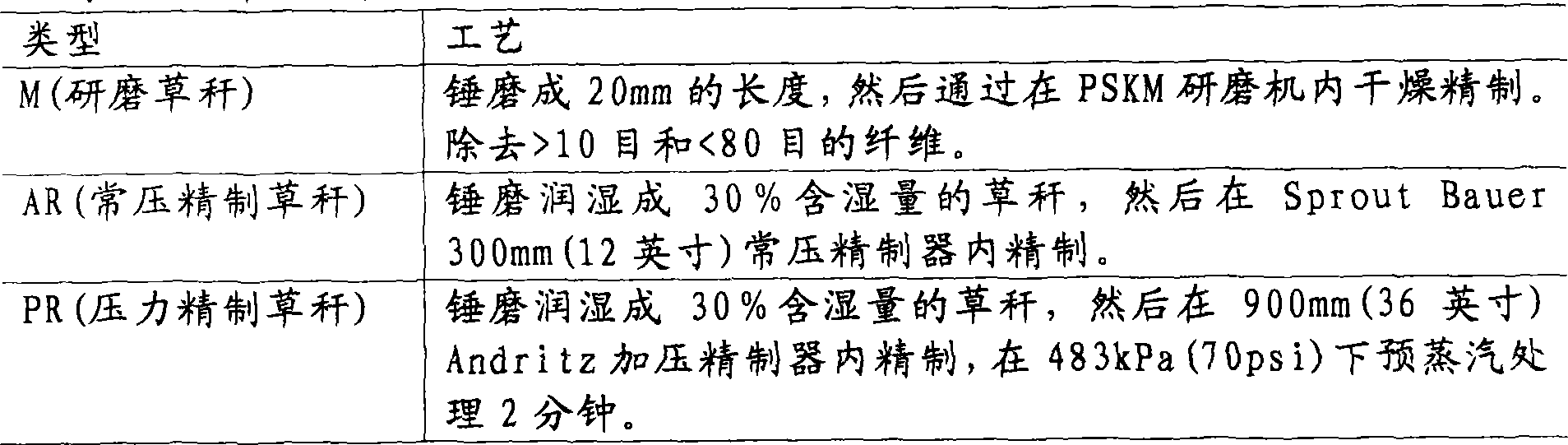

[0029] Grind grass stalks and refine them under atmospheric pressure or steam pressure, as shown in Table 1. The specific energy consumption during the refining process is about 250 kWh / ton of oven-dried straw.

[0030] Table 1: Preparation method of straw fiber

[0031]

Embodiment 2

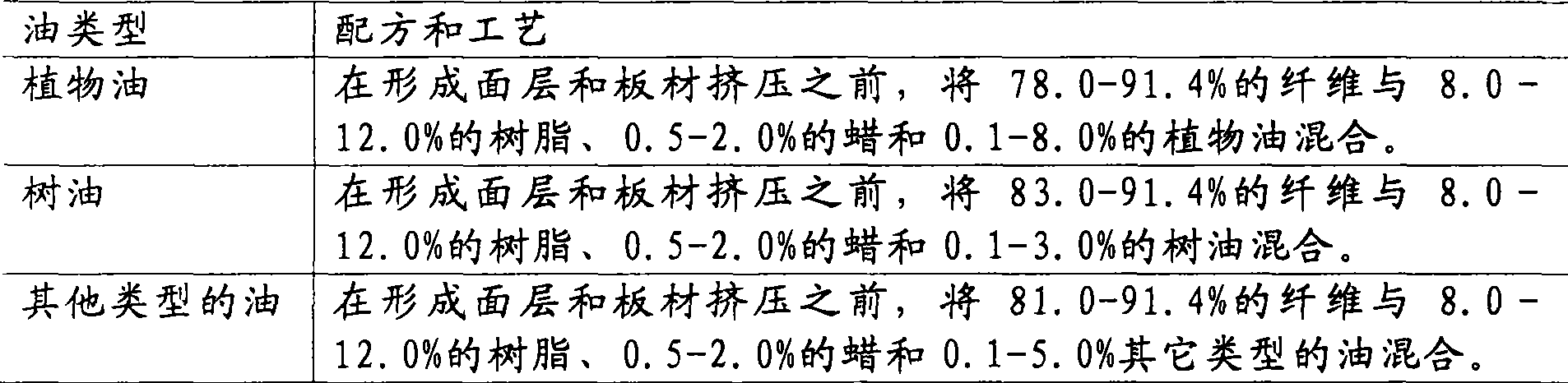

[0033]Table 2 lists different recipes for mixing certain percentages of fibers, resins, waxes and oils in high pressure gas lines or in blenders.

[0034] Table 2: Grass straw or wood fiber mixed with different oils

[0035]

Embodiment 3

[0037] Before making the MDF boards, the formulated fibers were analyzed using Inverse Gas Chromatography (IGC) to identify their dispersion and acid-base characteristics before and after oil addition. These characteristics are closely related to fiber bonding behavior according to the acid-base theory.

[0038] IGC measurements and MDF board test results showed significant changes in the dispersion and acid-base characteristics of the fibers, resulting in improved internal bond (IB) and dimensional stability of the board (i.e. less thickness swell (TS) and less water absorption (WA)). Depending on oil and fiber type, internal bond (IB) increased by 9-45% and thickness swell (TS) decreased by 30-72%, while bending properties remained constant or slightly improved.

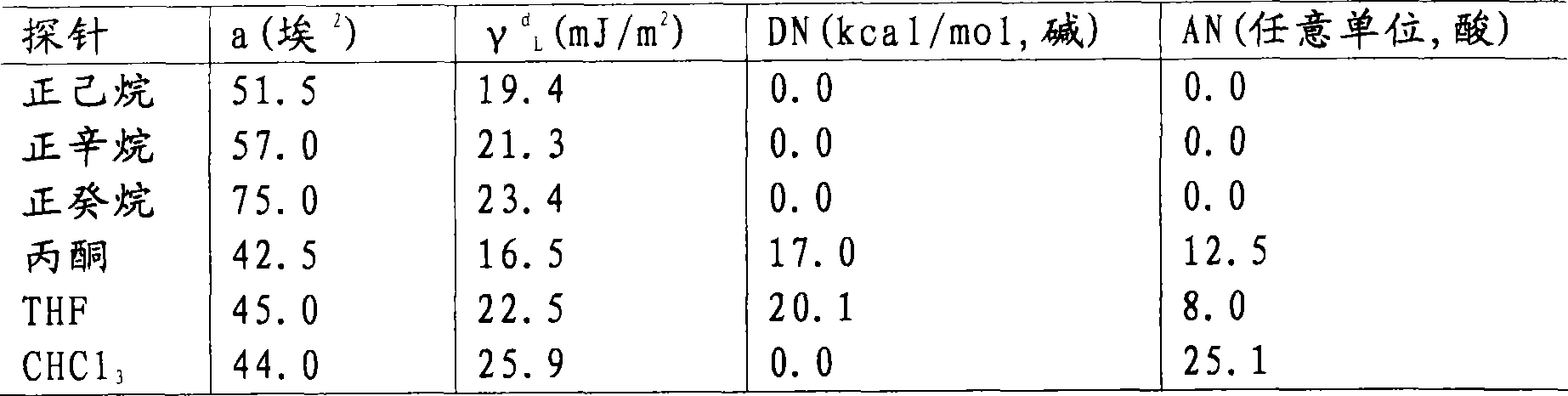

[0039] IGC measurements at infinite dilution were performed at 50°C. Helium is an inert carrier gas. The probes used in the IGC experiments are shown in Table 3, along with their molecular properties.

[0040] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com