Trace air seal leakage method

An air-tight, trace technology, used in the field of leak testing, which can solve problems such as low accuracy, data cannot be recorded and stored, and cannot be judged.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

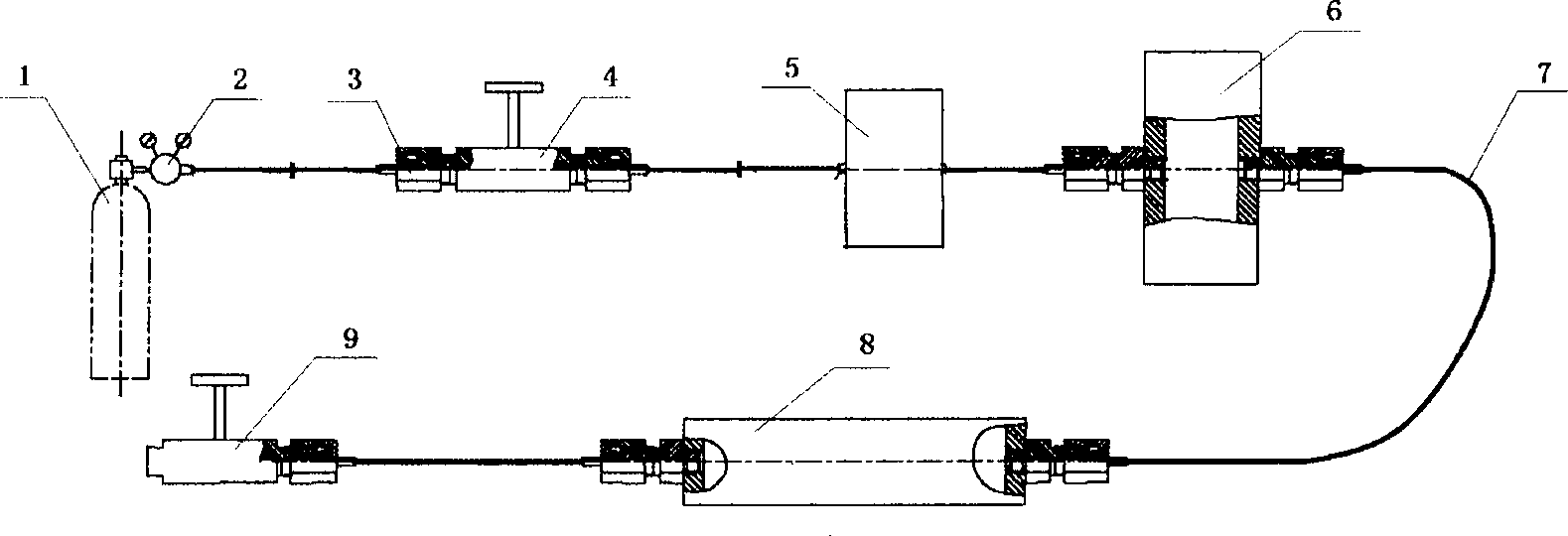

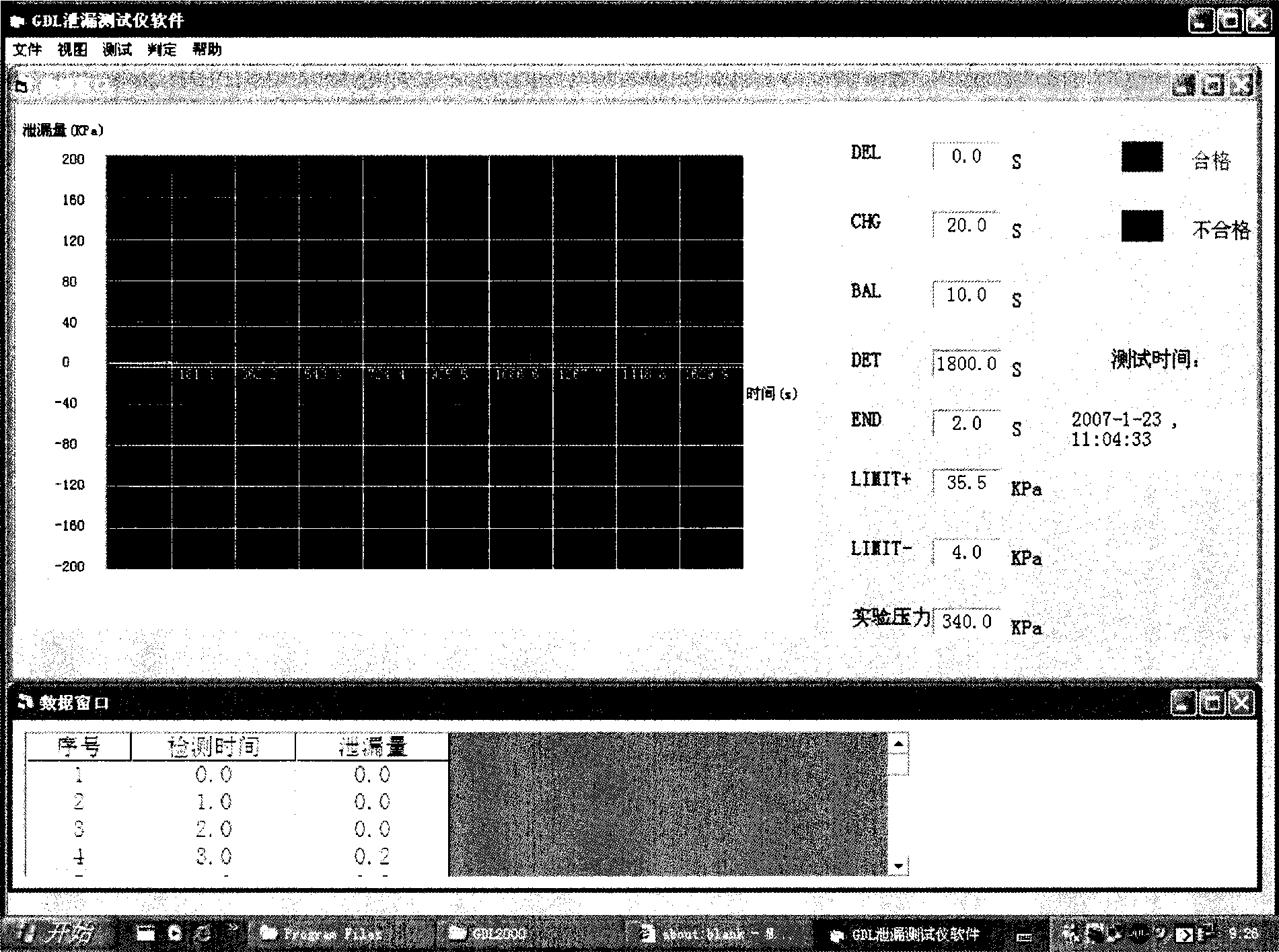

[0035] One method of leak-tight air sealing is:

[0036] The first step is to connect the pipeline: connect the deflation valve 9 at one end of the equipment gate sealing chamber 8, connect one end of the buffer tank 6 through the pipeline 7 at the other end of the equipment gate sealing chamber 8, and connect the other end of the buffer tank 6 with the One end of the air leak tester 5 is connected, the other end of the air leak tester 5 is connected with one end of the spherical connecting rod 3 through the stop valve 4, and the other end of the spherical connecting rod 3 is connected with the gas cylinder 1 through the pressure reducing valve,

[0037] Such as figure 1 shown;

[0038] The second step is to conduct a soap bubble test on the pipeline to check the tightness of the pipeline;

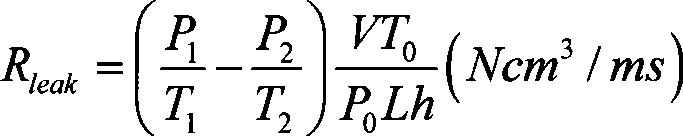

[0039] The third step, leakage calculation

[0040] The leakage from the double sealing gasket is calculated by the following calculation formula: P 2

[0041] R ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com