Oil lubricating structure

An oil and structure technology, applied in the direction of engine lubrication, pressure lubricant, lubricating parts, etc., can solve the problem of oil supply, inhalation into hydraulic devices such as oil pumps or valve bodies, and the front side of the bottom case. The oil return hole on the bottom surface of the main body case backflow to the first motor generator and power distribution device, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Exemplary embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

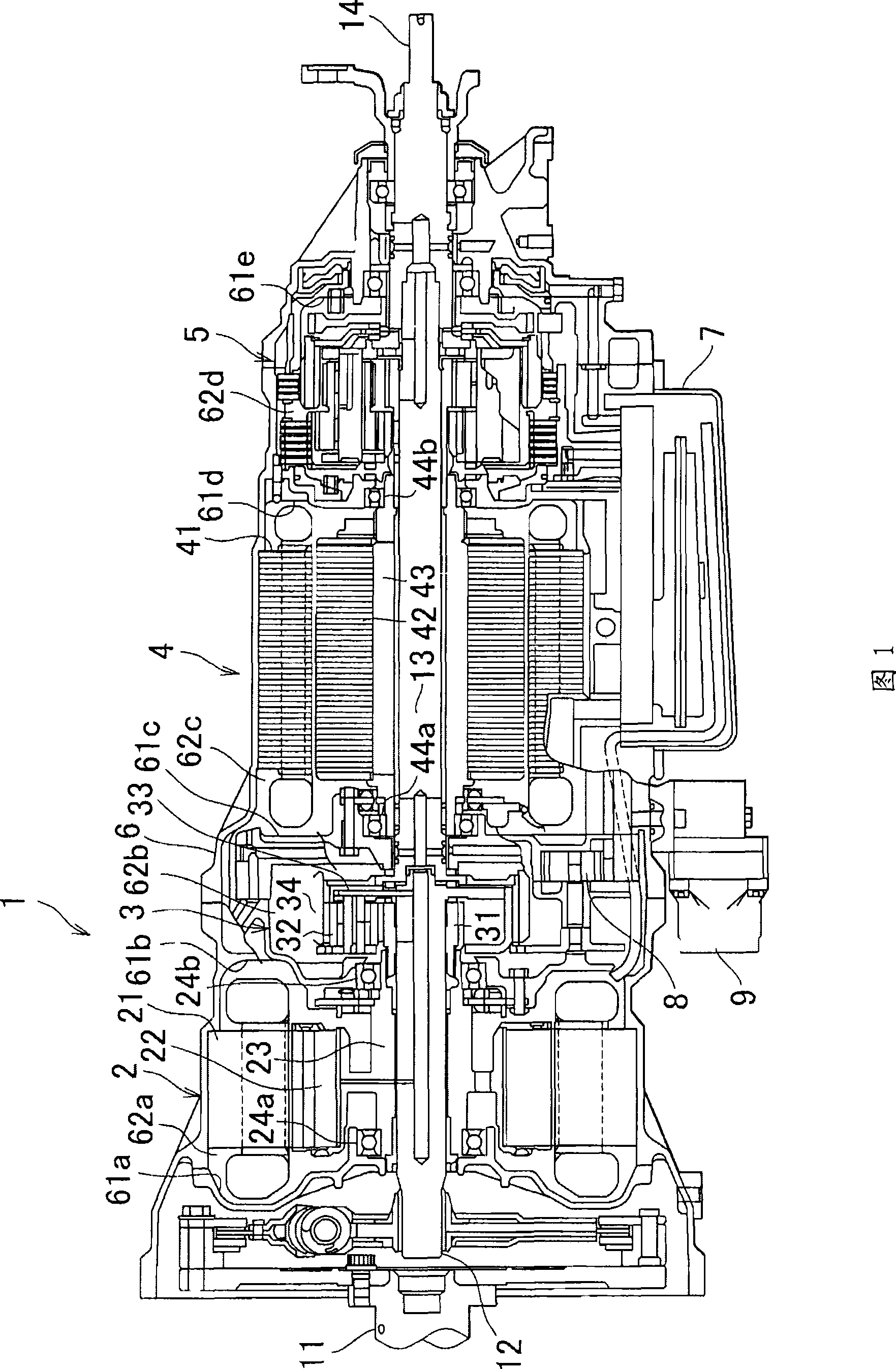

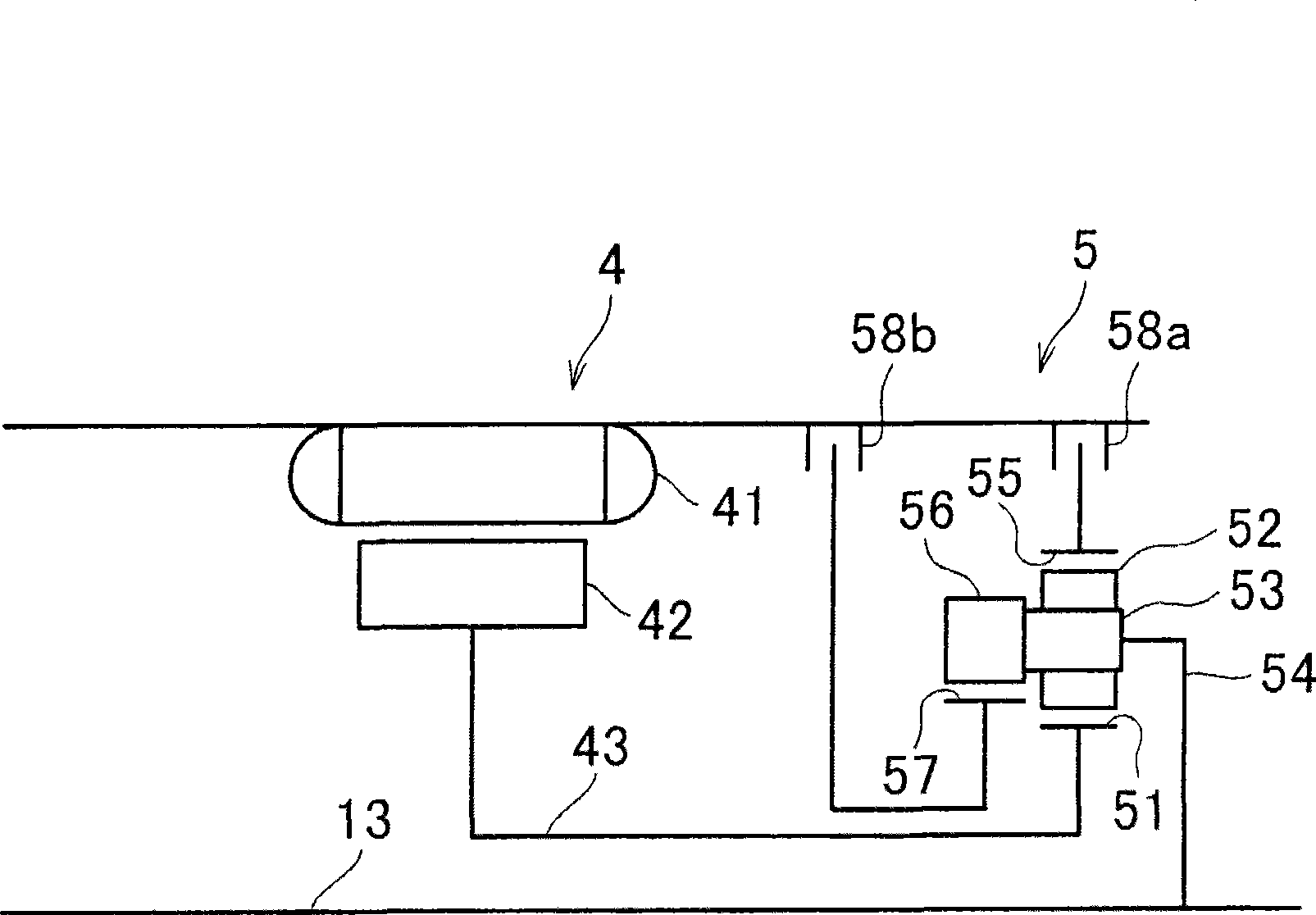

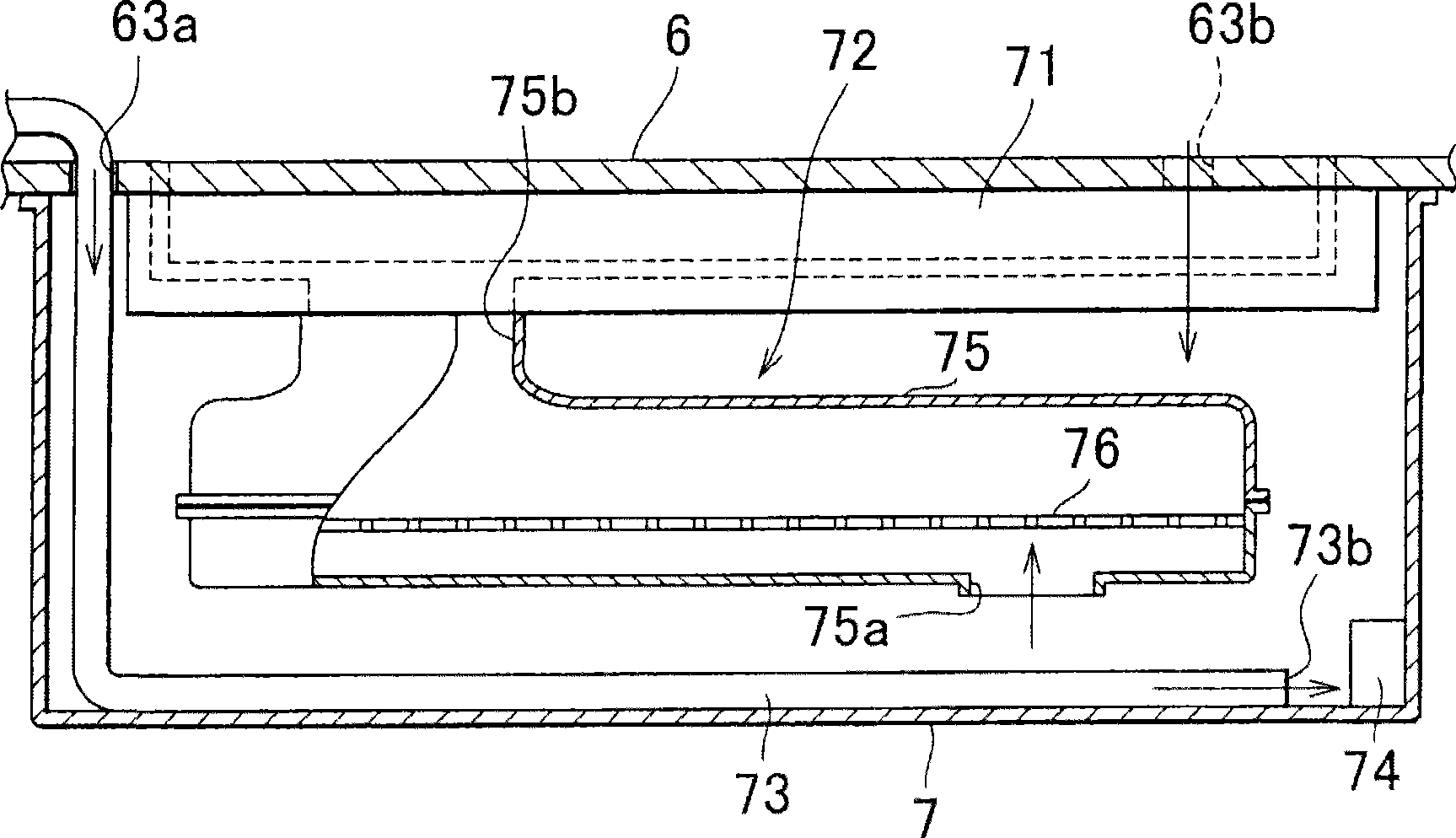

[0025] Figure 1 to Figure 5D is a diagram of a first exemplary embodiment of the oil lubricating structure of the present invention, and shows an example of the application of the present invention to a driving device of a hybrid vehicle.

[0026] First, this structure will be described. As shown in FIG. 1 , a hybrid electric vehicle driving device 1 is a dual-motor hybrid electric vehicle driving device. The front end portion shown on the left side of the figure is connected to an engine not shown via the crankshaft 11 , and the rear end portion shown on the right side of the figure is connected to a transmission shaft also not shown. The hybrid vehicle driving device 1 has a first motor generator 2, a power distribution device 3, a second motor generator 4, and a speed change device 5, all of which are supplied inside a housing 6 serving a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com