Thread profile modification for controlled stiffness

A technology of thread and external thread, applied in the field of thread pattern of clamping load holding force, can solve problems such as material deterioration, reduce bending stiffness and achieve the effect of fatigue resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The following description is merely exemplary in nature, and is not intended to limit the disclosure, application, or use. It should be understood that throughout the drawings, corresponding reference numerals indicate like or corresponding parts and features (eg, 22, 122, 222, etc.).

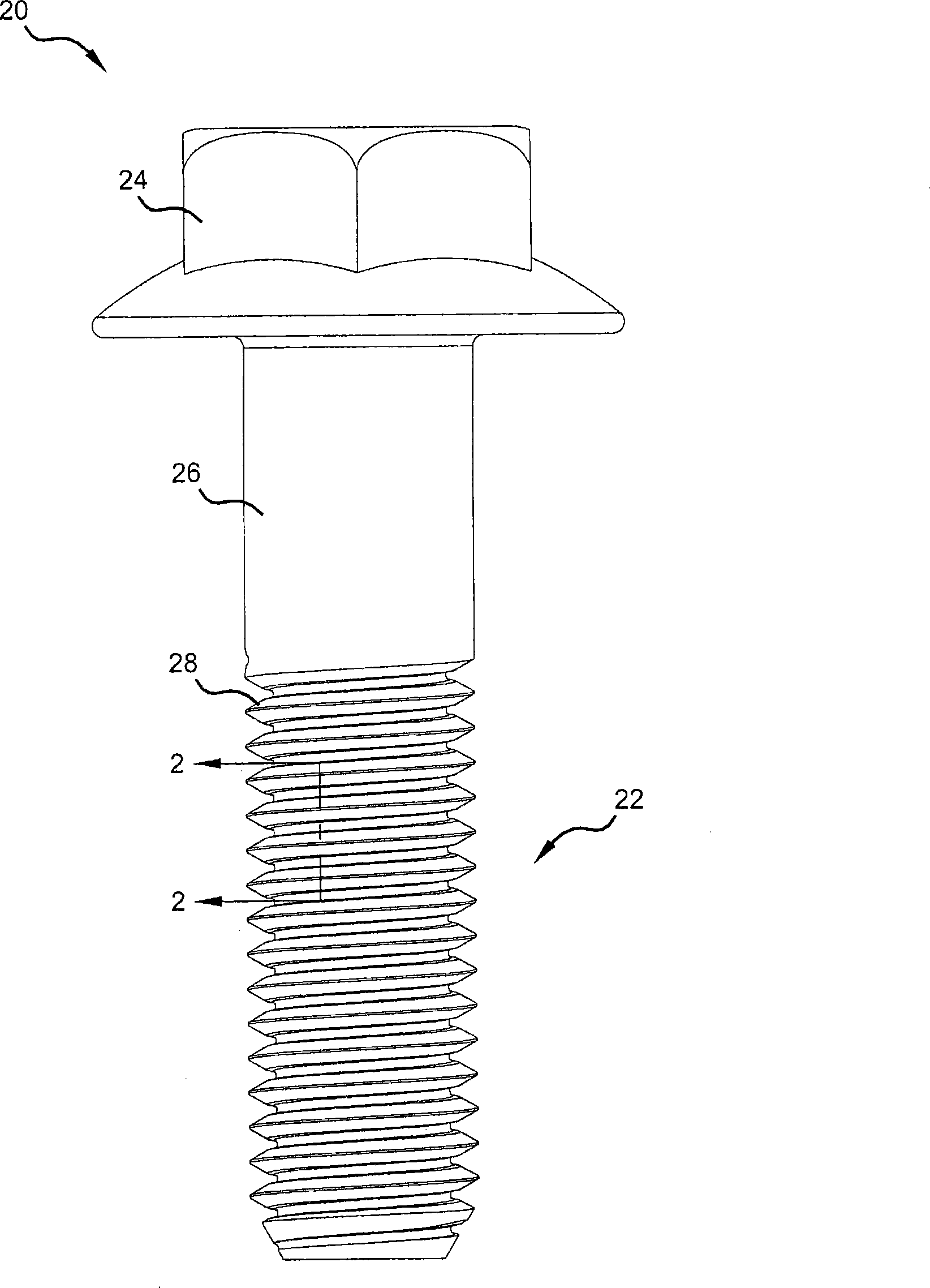

[0025] figure 1 A bolt 20 is shown having a thread form or pattern 22 in accordance with the present teachings. The bolt 20 includes a head 24 and a shank 26 between the head 24 and the threaded form 22 . However, it should be understood that the thread form 22 may extend all the way to the head 24 .

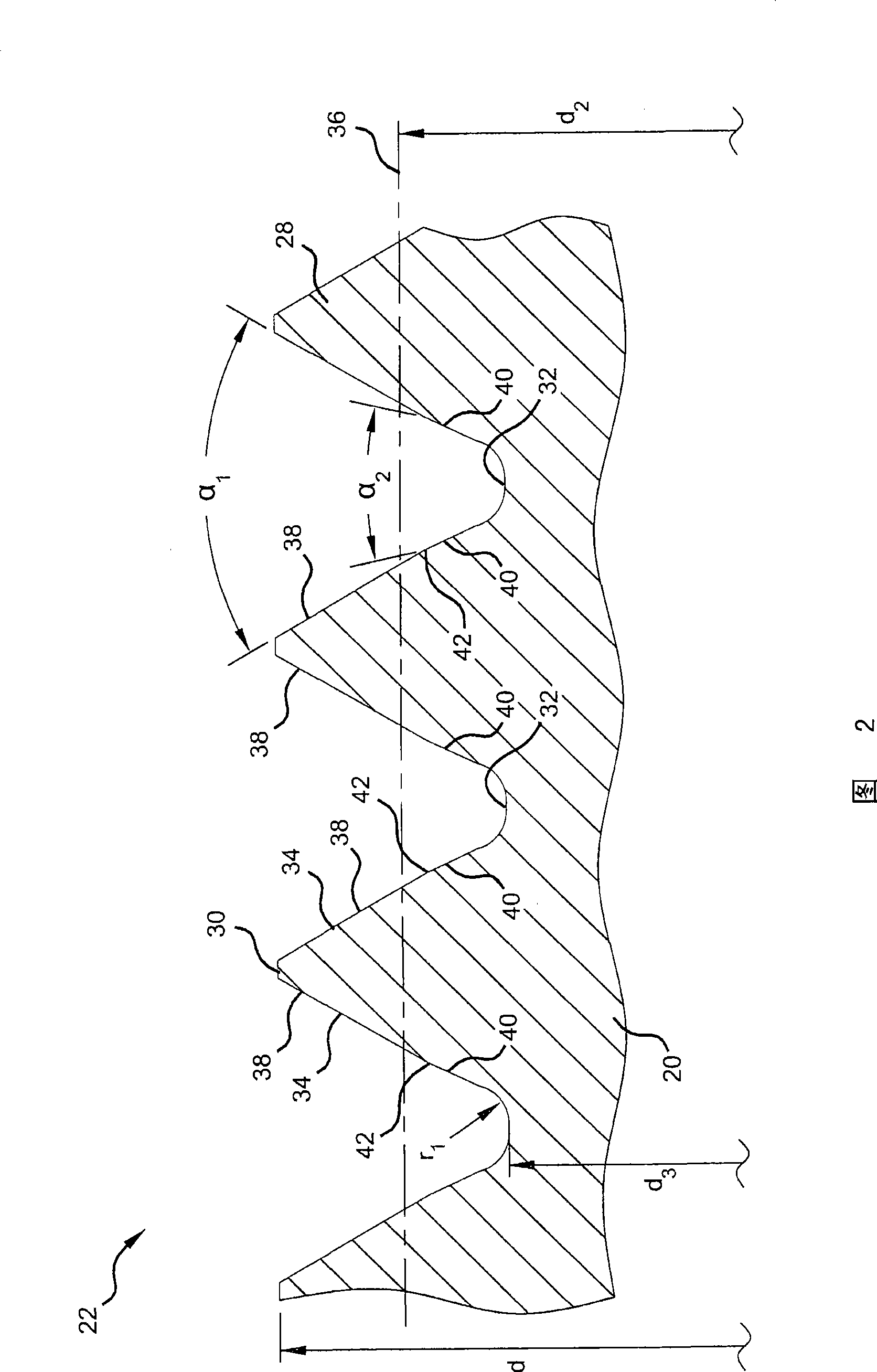

[0026] Referring now to Figure 2, which shows the figure 1 An enlarged fragmentary cross-sectional view of a portion of the thread form 22. The thread form 22 includes threads 28 extending helically along the bolt 20 . Thread 28 includes crests 30 and roots 32 . The crests 30 define the major diameter d of the bolt 20 and the bases 32 define the minor diameter d of the bolt 20 3 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com