Slice type bobbin feeler for pipe

A technology of pipe piece and weft finder, which is applied in the direction of textile, textile, papermaking, loom, etc., and can solve the problems that there is no weft finder for pipe piece air-jet loom

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

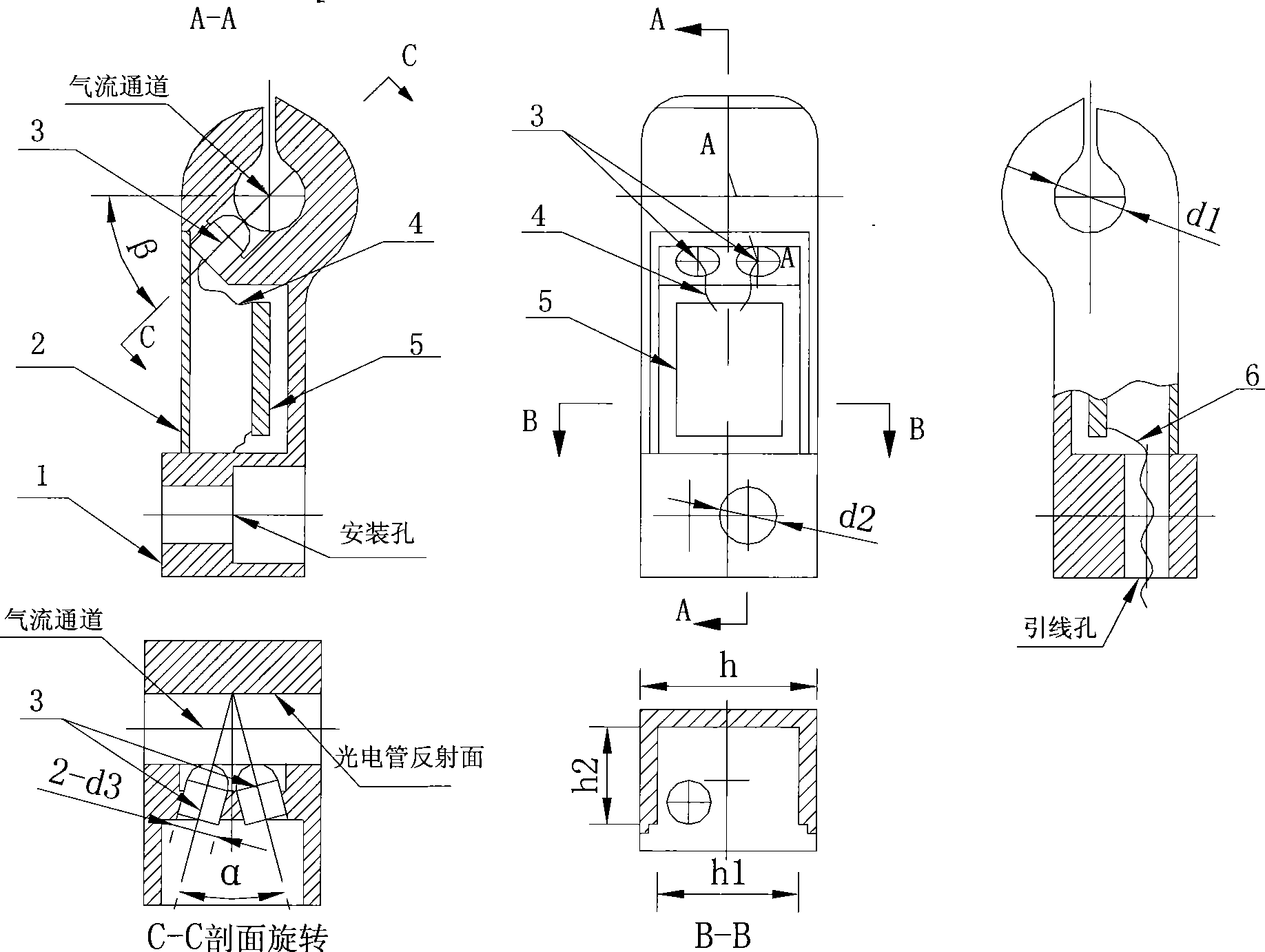

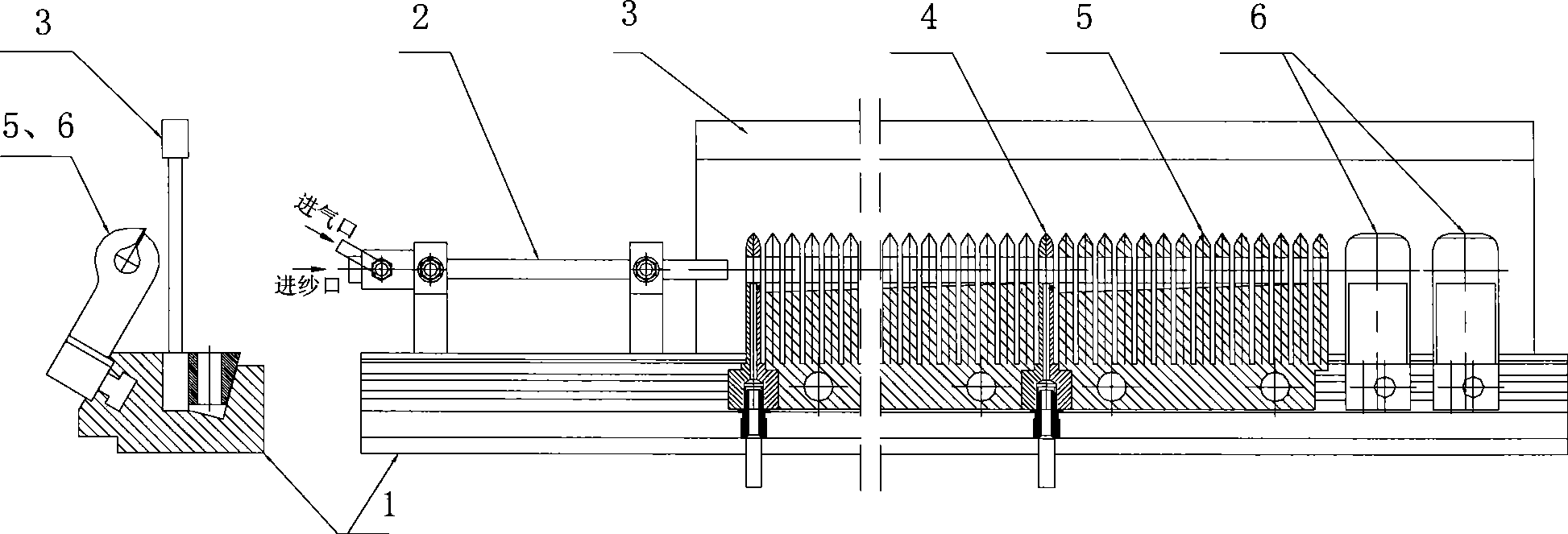

[0007] Such as figure 1 As shown, the pipe-type weft detector consists of the weft detector casing (1), the casing cover (2), the photoelectric cell (3), the photoelectric cell connection line (4), the control circuit board (5), the cable (6) composed of. The shape of the casing (1) of the weft finder is the same as that of the pipe piece (see A-A view), and it is formed by one-time pressing, and there is an "E"-shaped groove in the middle G pressing, which is used to accommodate the photoelectric cell connection line and the control circuit board and cables; two round holes with a diameter of d3 are processed on the top of the groove, which are used to install photoelectric tubes (one for the light-emitting tube and one for the receiving tube). The included angle is β to ensure that the reflective point is located on the inner arc surface of the "O" airflow channel of the casing; the two photocells do not expose the "O" shaped airflow channel and are hidden outside the chann...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com