Producing method of shuttlecock

A manufacturing method and technology for badminton, which can be applied to sports accessories and other directions, and can solve the problems of overweight and unbalanced badminton balls, and the inability to ensure the same angle of feather blades.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

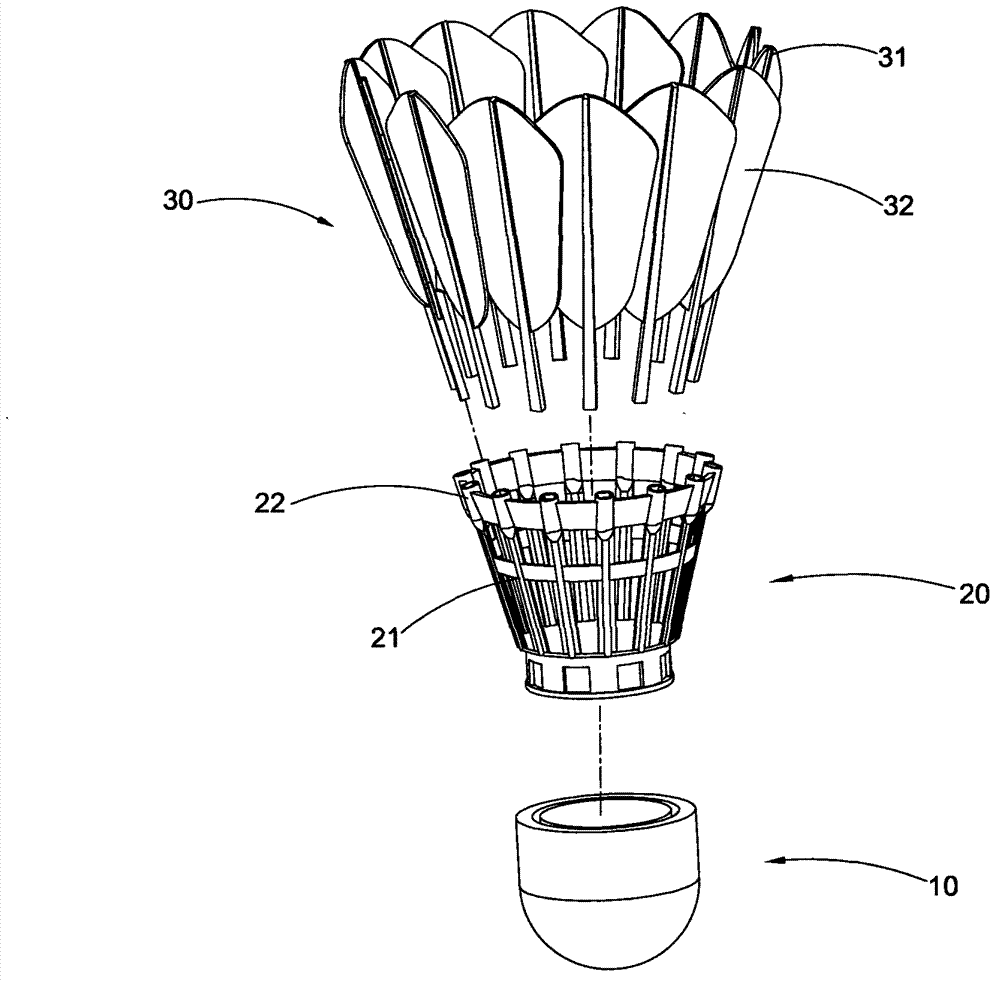

[0037] The invention provides a method for manufacturing a shuttlecock, the shuttlecock is a three-stage shuttlecock, such as figure 1 and figure 2 As shown, it includes a ball head 10, a hair-planting frame 20 and a group of feathers 30, and its structure has been disclosed in the applicant's previous Chinese patent applications 200910044168.1, 201010226568.7, 201110028436.8, and 201110418724.4, the entire content of these patents This application is incorporated by reference in its entirety.

[0038] The shuttlecock of the present invention is significantly different from the shuttlecock in the prior art. The traditional shuttlecock does not have a hair planting frame, and the hair stem of the feather is directly inserted on the ball head. The traditional shuttlecock belongs to the two-stage shuttlecock, that is to say, the traditional shuttlecock only Includes feather and ball head. It also requires winding to maintain the shape and taper of the shuttlecock.

[0039] Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com