Soap-free core-shell emulsion type amphiphilic polymer resin and preparation and application thereof in preparation of function humidity controlling coating

An amphiphilic polymer, core-shell emulsion technology, applied in the polymer field, can solve the problems of high minimum film-forming temperature, increased product cost, affecting coating performance, etc., and achieves low product cost, low film-forming temperature, ultra-high The effect of strong permeability

Inactive Publication Date: 2011-01-05

NORTHWEST NORMAL UNIVERSITY

View PDF0 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, the minimum film-forming temperature of emulsion-type and soap-free emulsion-type resins is relatively high, generally above 15°C, and it is difficult to form a good film at low temperature without adding film-forming aids, which will affect the coating performance.

However, the film-forming aid is a kind of temporary plasticizer that is easy to disappear and has a certain volatilization rate. The price is relatively high, and the cost of the product will increase after addition. Bioresin is more realistic

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

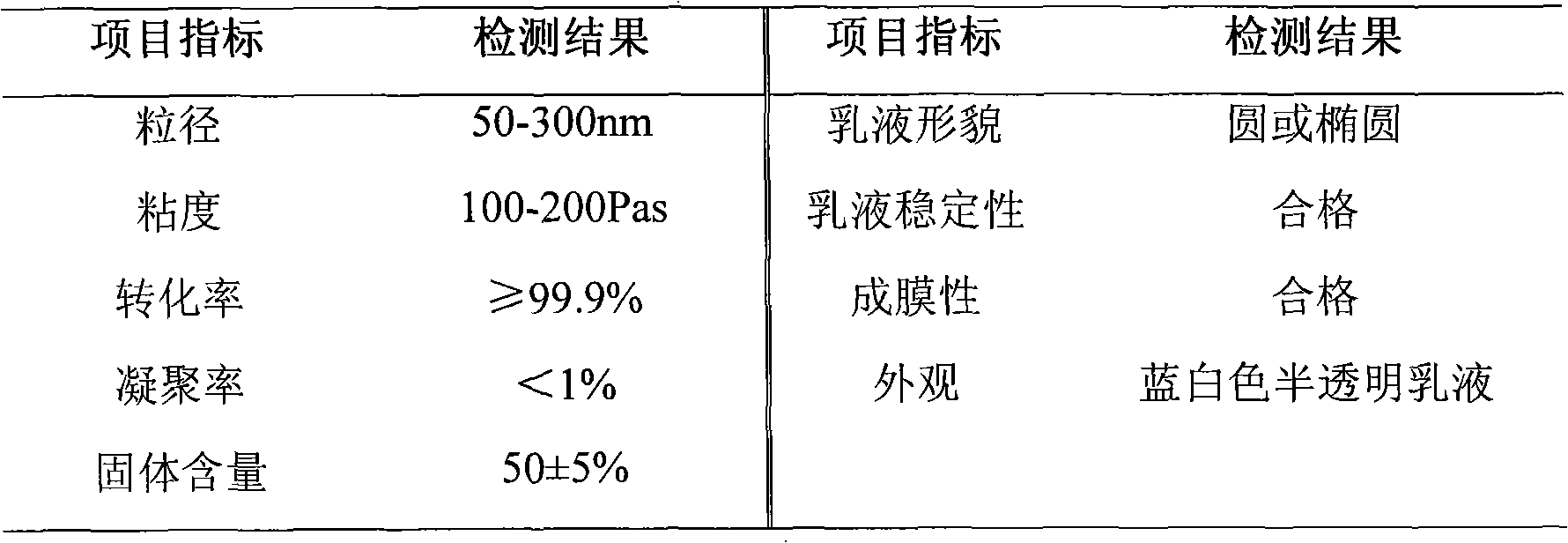

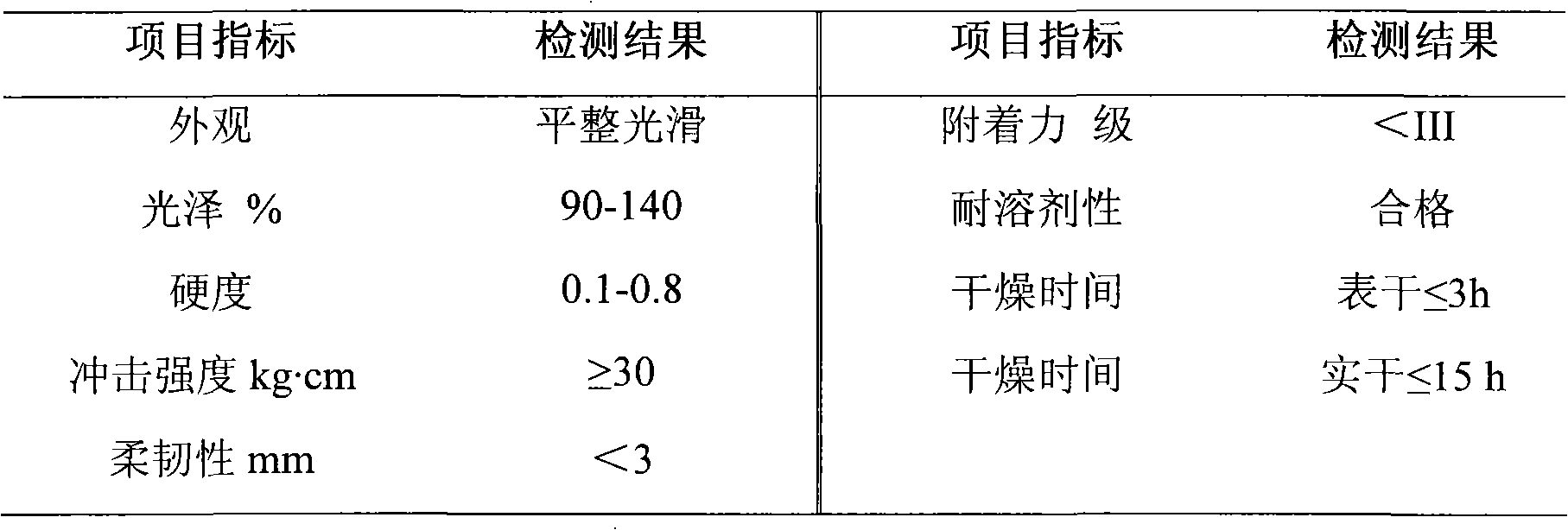

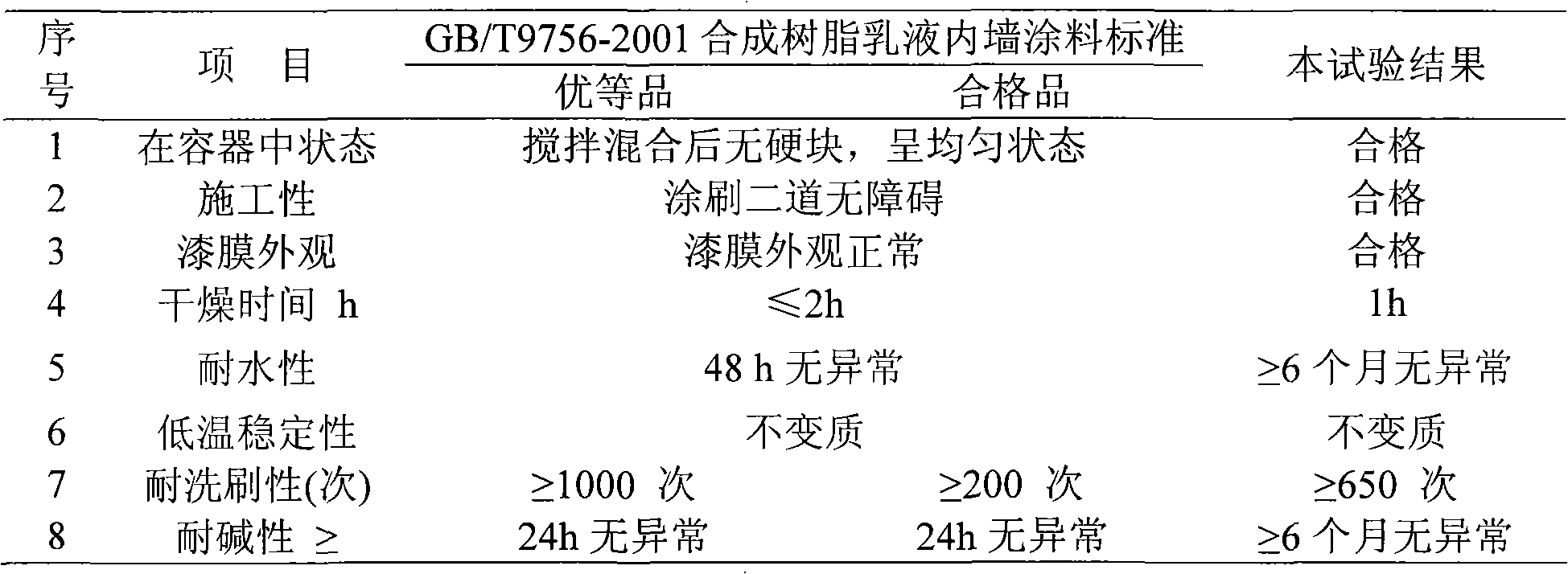

The invention provides a nonsoap nuclear shell latex type amphipathic polymer resin, which is polymerized from methyl methacrylate, styrene, methyl methacrylate, butyl methacrylate, butyl acrylate, hydroxypropyl methacrylate, hydroxyethyl methacrylate, acrylamide, diacetone acrylamide and other monomers. The nonsoap nuclear shell latex type amphipathic polymer resin is used as a main film formingmaterial for a paint and is combined with various inorganic macromolecular fillers to prepare the paint; the prepared paint integrates decoration, dampness regulation, permeability, heat insulation, dewing resistance, water and alkali resistance, antisepsis and the like, and can also prevent a coating film from falling off caused by various leakage and water condensation of a wall body so that the coating film is more lasting and durable; and the paint contains no organic solvent and no emulsifier, is safer and more environment-friendly, and has more superior coating property.

Description

Soap-free core-shell emulsion type amphiphilic polymer resin and its preparation and application in the preparation of functional moisture-regulating coatings technical field The invention belongs to the technical field of macromolecules, and relates to a polymer resin, in particular to a soap-free core-shell emulsion type amphiphilic polymer resin with hydrophilicity and lipophilicity and a preparation method thereof, and the invention also relates to the soap-free core-shell emulsion type amphiphilic polymer resin Application of shell emulsion type amphiphilic polymer resin in the production of functional moisture-regulating coatings. technical background Relative air humidity is an important parameter to measure the indoor environment. It is closely related to human health and work and life. If it is too high or too low, it will affect people's normal life. Considering various factors such as microbial growth, human disease, item deterioration, and comfort, it is recogn...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C08F220/14C08F212/08C08F220/18C08F2/22C08F2/44C08K3/36C09D133/12C09D133/08C09D125/08C09D5/00C08F220/06C08F220/28C08F220/56C08F222/02

Inventor 王荣民吕维华何玉凤熊玉兵王俊峰

Owner NORTHWEST NORMAL UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com