Method for preparing tert-butanol by extraction of carbon 4 hydrocarbon containing isobutene

A carbon tetrahydrocarbon and tert-butanol technology, applied in the field of continuous production of tert-butanol, can solve the problems of high energy consumption, reduced equipment utilization rate, etc., and achieves the advantages of reducing energy consumption, improving conversion rate and selectivity, and saving equipment investment costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

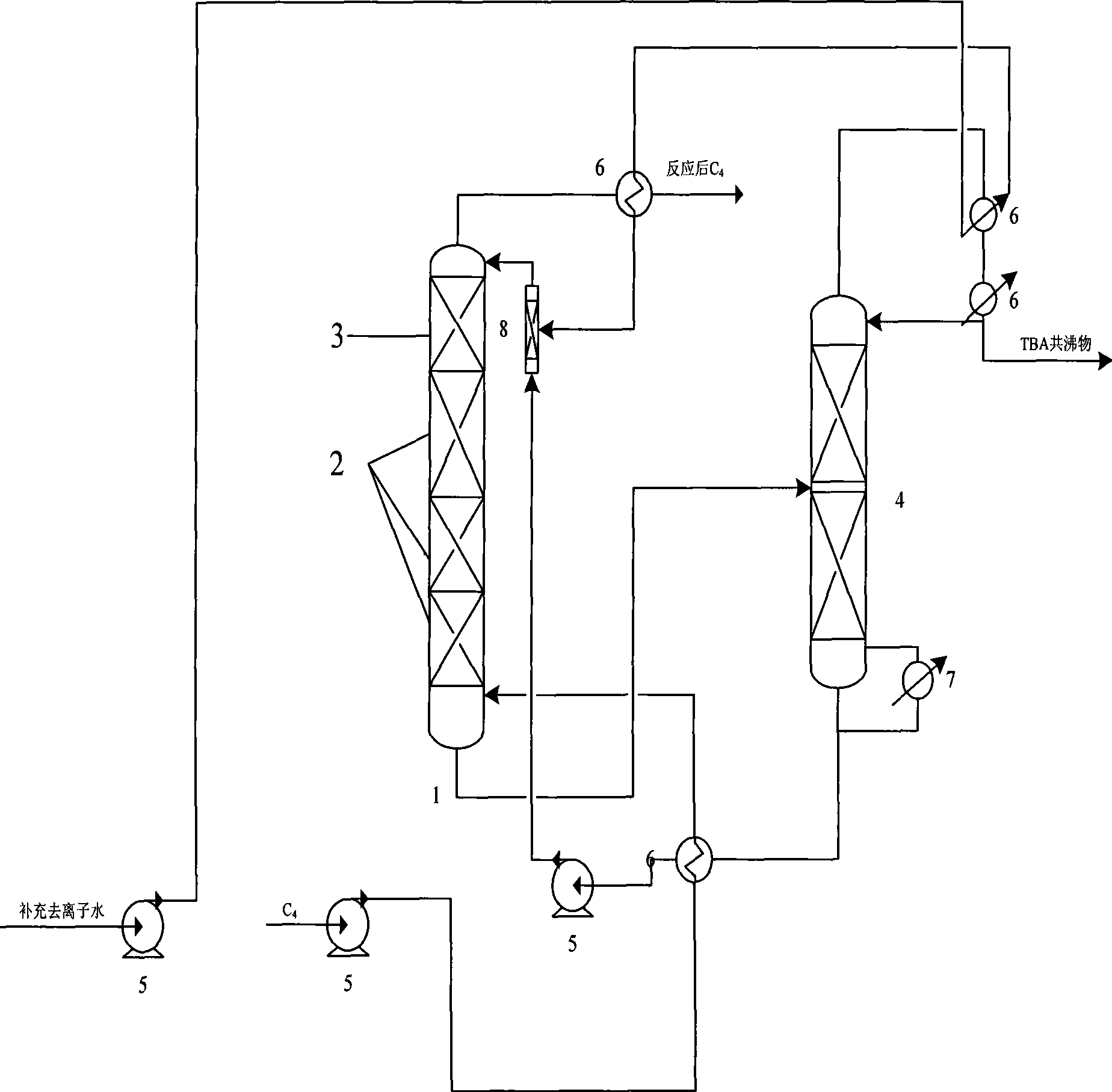

Image

Examples

Embodiment 1

[0021] exist In the 100×11000mm reactive extraction tower, it is loaded in four sections in bulk 5×5mm cylindrical cation exchange resin catalyst, the total height of the catalyst is 10 meters, and the loading capacity of the catalyst is 70L. The specific surface area of the catalyst is 42m 2 / g, the exchange equivalent is 4.3mmol / g (dry basis), the porosity of the catalyst bed is 50%, and the top of the catalyst bed is filled 6×6mm porcelain Raschig ring 0.5m. At a pressure of 2.0MPa, a reaction temperature of 85°C, water / C 4 = 4(v / v), C 4 The isobutene concentration in the medium is 38.35wt%, C 4 At a flow rate of 0.4mm / s, C 4 The isobutene in the process is operated through continuous reaction extraction, the conversion rate of isobutene is 94.2%, the selectivity is 100%, and the C 4 Does not contain TBA.

Embodiment 2

[0025] Composition with the same raw material of embodiment 1, in the reactive extraction tower among the embodiment 1, the catalyzer and the ceramic Raschig ring filler of packing same same amount, at pressure 2.0MPa, under 85 ℃ of temperature, C 4 At a flow rate of 0.5mm / s, C 4 Continuously carry out reactive extraction operation with water in the tower, when water / C 4 =8(v / v), C 4 The conversion rate of isobutene in the medium can reach 95.0%, and the selectivity is 100%; when water / C 4 =10(v / v), C 4 The conversion rate of isobutene can reach 99.4%, and the selectivity is 100%.

Embodiment 3

[0027] Adopt temperature of reaction in embodiment 1, pressure, water / C 4 (v / v) ratio and containing isobutene are 18.72wt% C4 hydrocarbons as raw material, in In the reactive extraction tower of 32 * 8000mm, the catalyst 6L identical with embodiment 1 is charged in 4 sections, in C 4 When the flow rate is 0.45mm / s, the continuous reaction extraction, the conversion rate of isobutene reaches 90.21%, and the selectivity is 100%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com