High pressure membrane anchor double uniform stream chilled glass furnace

A glass furnace and film-piercing technology, applied in glass tempering, glass manufacturing equipment, manufacturing tools, etc., can solve the problems of thermal insulation cotton slag, fly ash, etc. improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

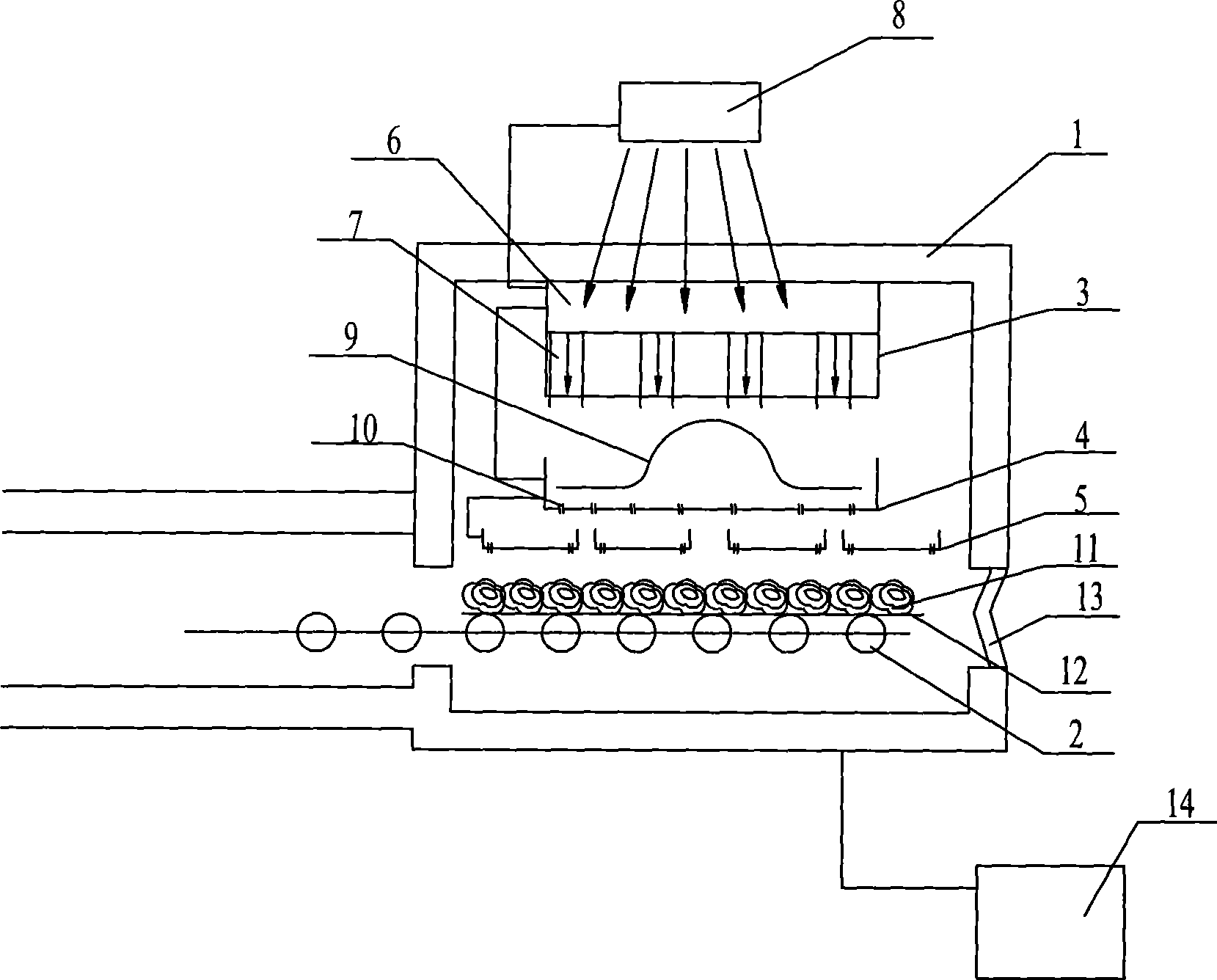

[0018] The present invention will be described in further detail below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited thereto.

[0019] As shown in the accompanying drawings, a high-pressure film-penetrating double uniform flow tempered glass furnace includes a furnace body 1 and a roller table composed of rotating rollers 2. A roller table is set at the furnace door 13 in the inner cavity of the furnace body 1. In the inner chamber space of the upper furnace body 1, the super-grade convection equation 3, the first-level convection equation 4, and the second-level convection equation 5 are arranged in sequence from top to bottom, and each equation is connected with a circuit to form a high-pressure membrane-penetrating double uniform flow system . Further, the super-grade convection equation 3 is made of heat-insulating material, and a Tai Chi vortex device 6 is arranged on its top, and a convection heat-resistan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com