Gluer, temperature control device and heat conduction mechanism

A technology of temperature control device and gluing machine, which is applied in lamination device, temperature control by electric mode, control of lamination, etc. It can solve the problems of loss, affecting the quality of gluing, overcooling, etc., and increase the contact area , Guarantee the quality of the glue and avoid the effect of being invalid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the objectives, technical solutions, and advantages of the embodiments of the present invention clearer, the present invention will be described in further detail below with reference to the accompanying drawings and the embodiments.

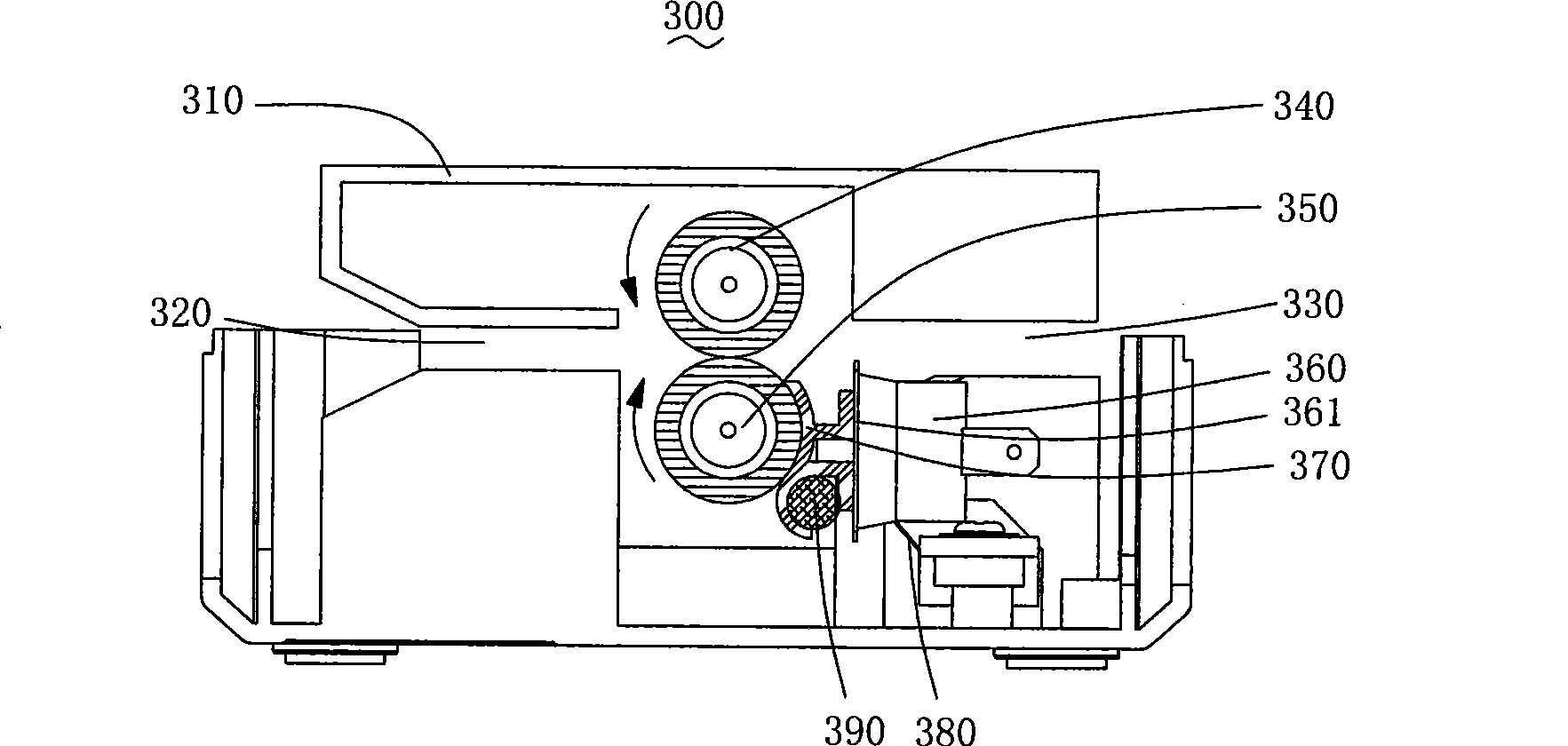

[0027] refer to image 3 , is a schematic cross-sectional view of the first embodiment of the gluing machine of the present invention. The gluing machine 300 includes a housing 310 , an inlet 320 , an outlet 330 , an upper rubber roller 340 , a lower rubber roller 350 , and a temperature control device 360 . The upper rubber roller 340 and the lower rubber roller 350 are arranged in parallel and next to each other, and are driven to rotate by motors and gears (not shown).

[0028] The upper rubber roller 340 and the lower rubber roller 350 are inner heating silicone rollers, which can be referred to figure 2 , The upper rubber roller 340 or the lower rubber roller 350 respectively includes a heating wire in the middl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com