Environment simulating sustained-release storage system and preparation method thereof

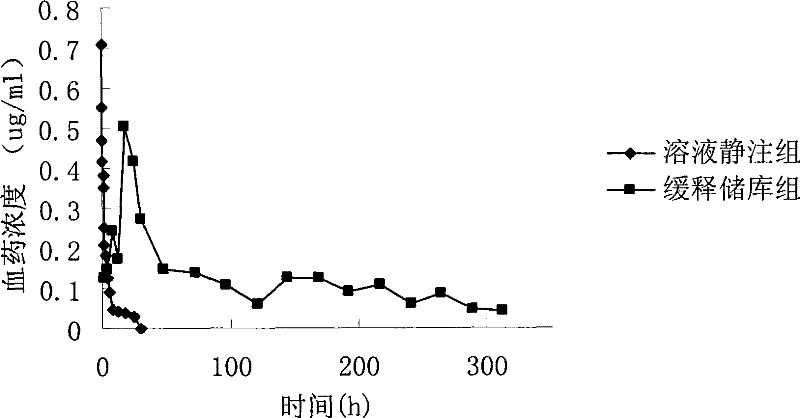

A slow-release and storage technology, which is used in pharmaceutical formulations, medical preparations with non-active ingredients, and emulsion delivery to achieve sustained and smooth drug release, solve the problem of sudden release, and improve temperature-sensitive and phase-sensitive properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Weigh 25g of poloxamer 407, add 100ml of water for injection to make a solution with a certain concentration, and let it stand in a refrigerator at 4°C overnight to fully dissolve it. Observe its appearance at 4°C; then place it in an environment of 37°C for 10 minutes to observe its appearance.

[0042] Results: The poloxamer 407 solution prepared at low temperature was transparent and had a certain consistency. As the temperature increases, the viscosity increases until it becomes a transparent solid (gel), which does not flow when the container is tilted. When the gel was brought to low temperature again, it regained its fluidity.

[0043] Weigh 150g of poloxamer 407, add 500ml of water for injection, and configure a solution with a certain concentration as the water phase. Dissolve 30 g of PLGA (molecular weight: 50,000, LA:GA=70:30) and 1 g of risperidone in 100 ml of triethyl citrate, then add 3 g of stearic acid and shake to form the oil phase. The water phase...

Embodiment 2-11

[0045] Repeat the steps of Example 1 with different types of thermosensitive hydrophilic materials, biodegradable polymers, solid lipids, and organic solvents, as shown in Table 1:

[0046] Table 1 Description of reservoir morphology composed of different types of thermosensitive hydrophilic materials, polymers, solid lipids, and organic solvents

[0047] Reality

Embodiment 12

[0049] Get 50ml benzyl alcohol (BA) and 50ml glyceryl triacetate (GT) and mix evenly, accurately take methotrexate 2g and 10g glyceryl monostearate and mix and dissolve in the above-mentioned mixed solvent, then take 10gPLGA (molecular weight 20,000 , LA:GA=50:50) was added to the above mixed solution, and shaken at 37°C until it was completely dissolved to form a transparent and uniform solution, which was used as the oil phase.

[0050] Dissolve 100 g of poloxamer 407 in 500 ml of water for injection as the water phase.

[0051] Under the condition of ice bath, the oil phase was added dropwise into the water phase, and stirred at a high speed of 16000r / min for 3min to form an O / W emulsion. That is, the environment-promoted sustained-release storage system is prepared.

[0052] Observe the state of the emulsion at 4°C and 37°C, and observe the morphology of the emulsion under an optical microscope.

[0053] Results: The prepared O / W emulsion was in liquid state at 4°C. As t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com