Idle load controllable initiating and stepless speed regulating device used for overload mechanical apparatus

A technology of stepless speed regulation and mechanical equipment, applied in the direction of mechanical equipment, transmission device, gear transmission device, etc., can solve the problems of high price, high maintenance cost, complicated control, etc., to reduce difficulty and cost, prolong service life, The effect of shortening the impact time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

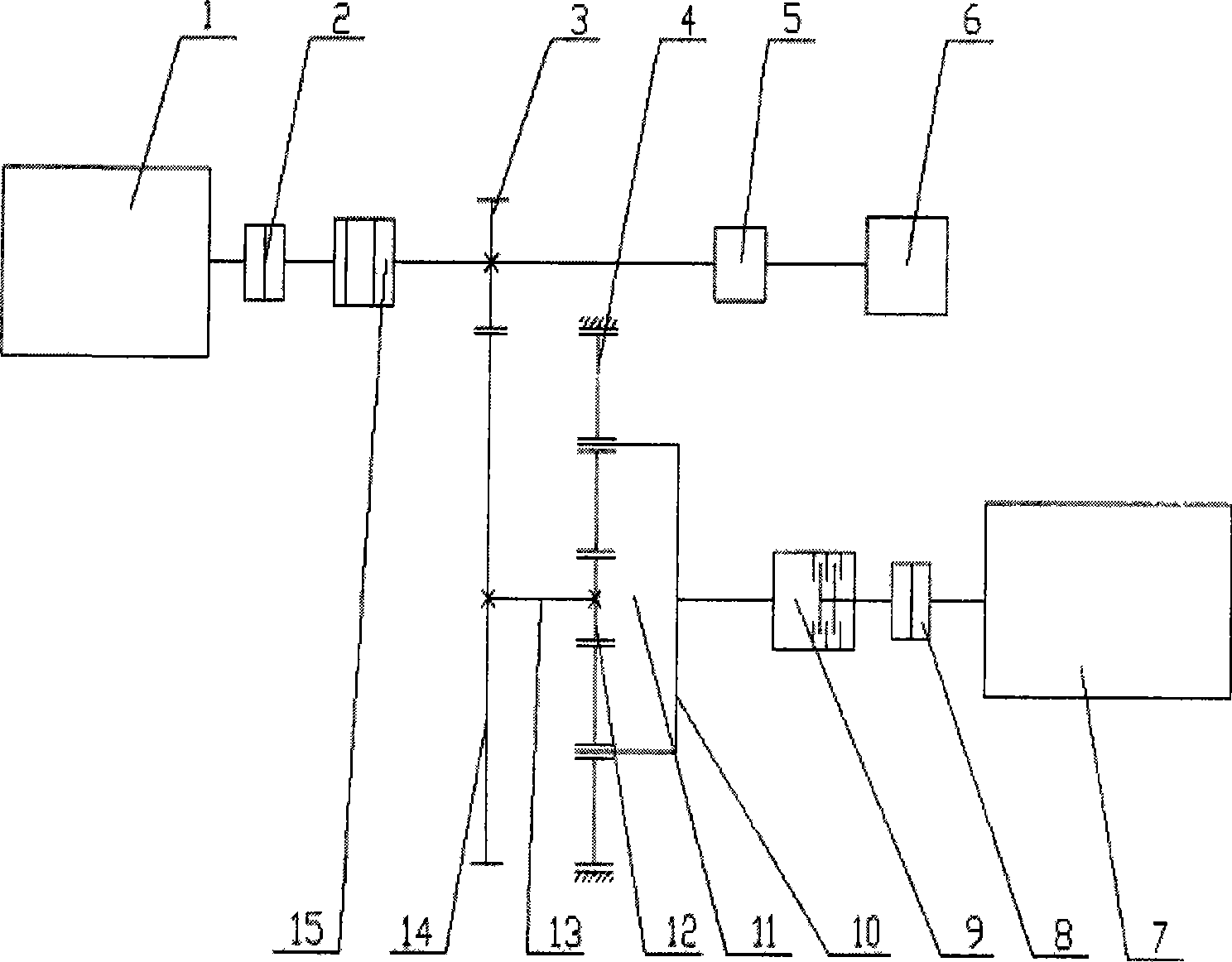

[0015] Below in conjunction with accompanying drawing, the present invention is described in further detail:

[0016] Such as figure 1 As shown, the no-load controllable start and stepless speed regulation device of heavy-duty mechanical equipment mainly includes no-load start system, deceleration system, hydraulic viscous speed regulation clutch and brake. Among them, the no-load starting system is composed of a main motor 1, an auxiliary motor 6 and a clutch 5 connected with the auxiliary motor 6; the reduction system is composed of a first-stage gear reduction mechanism and a first-stage planetary reduction mechanism 11; Speed clutch 9 is arranged on the reduction system output shaft. The brake 15 is arranged between the main motor coupling 2 and the reduction system. The planetary reduction mechanism 11 in this device includes a sun gear 12 as an input component, a ring gear, three planetary gears 4, and a planet carrier 10 as an output component, and the ring gear is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com