Light beam translation electric control device and method based on Goos-Hanchen displacement effect

A technology of beam translation and Gus-Hanchen, applied in the field of lasers, can solve the problems of high experimental conditions and environments for two-level atomic media, and difficulty in applying to general environments.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Such as figure 1 As shown, the electric beam translation control device based on the Gus-Hanchen displacement effect involved in this embodiment includes a prism 1, an upper metal film 2, a lithium niobate wafer 3, a lower metal film 4, an air gap 5, and a DC voltage source 6. The bottom surface of the prism 1 is coated with the upper metal film 2, and the lower surface of the lithium niobate wafer 3 is coated with the lower metal film 4. The bottom surface of the prism 1 is parallel to the surface of the lithium niobate wafer 3, and the two are rigidly fixed by a metal bracket. There is an air gap 5 between the lithium niobate wafers 3, forming a double-sided metal-clad waveguide structure composed of an upper metal film-air gap-lithium niobate wafer-lower metal film. The upper metal film 2 and the lower metal film 4 are coated with The electrodes are externally connected to a DC voltage source 6 .

[0040] The upper metal film 1 is made of gold or silver, with a thic...

Embodiment 2

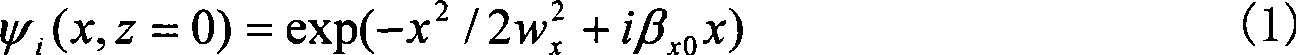

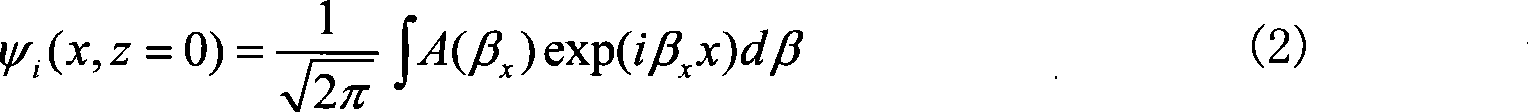

[0046]The beam translation electric control method based on the Gus-Hanchen displacement effect involved in this embodiment takes a wavelength of 860 μm as an example. At this wavelength, the optical refractive index of lithium niobate o is 2.392, and the electro-optic coefficient is γ 13 =8.27pm / V, the piezoelectric coefficient is d 33 =8pm / V.

[0047] In the first step, two layers of metal films 2 and 4 are respectively plated on the bottom surface of a polished prism 1 and the lower surface of a lithium niobate wafer 3, and the bottom surface of the prism 1 is adjusted to be parallel to the surface of the lithium niobate wafer 3, and the two are connected by a metal support. Rigidly fixed, there is an air gap 5 between the prism 1 and the lithium niobate wafer 3, forming a double-sided metal-clad waveguide structure composed of an upper metal film-air gap-lithium niobate-lower metal film.

[0048] In the second step, the light beam is incident on the upper metal film 2 on ...

Embodiment 3

[0055] The beam translation electric control method based on the Gus-Hanchen displacement effect involved in this embodiment takes a wavelength of 860 μm as an example. At this wavelength, the optical refractive index of lithium niobate o is 2.392, and the electro-optic coefficient is γ 13 =8.27pm / V, the piezoelectric coefficient is d 33 =8pm / V.

[0056] In the first step, two layers of metal films 2 and 4 are respectively plated on the bottom surface of a polished prism 1 and the lower surface of a lithium niobate wafer 3, and the bottom surface of the prism 1 is adjusted to be parallel to the surface of the lithium niobate wafer 3, and the two are connected by a metal support. Rigidly fixed, there is an air gap 5 between the prism 1 and the lithium niobate wafer 3, forming a double-sided metal-clad waveguide structure composed of an upper metal film-air gap-lithium niobate-lower metal film.

[0057] In this embodiment, gold is selected as the metal material, the refractive ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com