Conductive and continuous casting type electroslag remelting furnace for crystallizer

A technology of electroslag remelting furnace and crystallizer, which is applied in the field of crystallizer conduction and continuous casting electroslag remelting furnace, can solve the problems of complex production process, high production power consumption and high production cost, and achieve low production cost and electricity consumption The effect of increasing consumption and yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

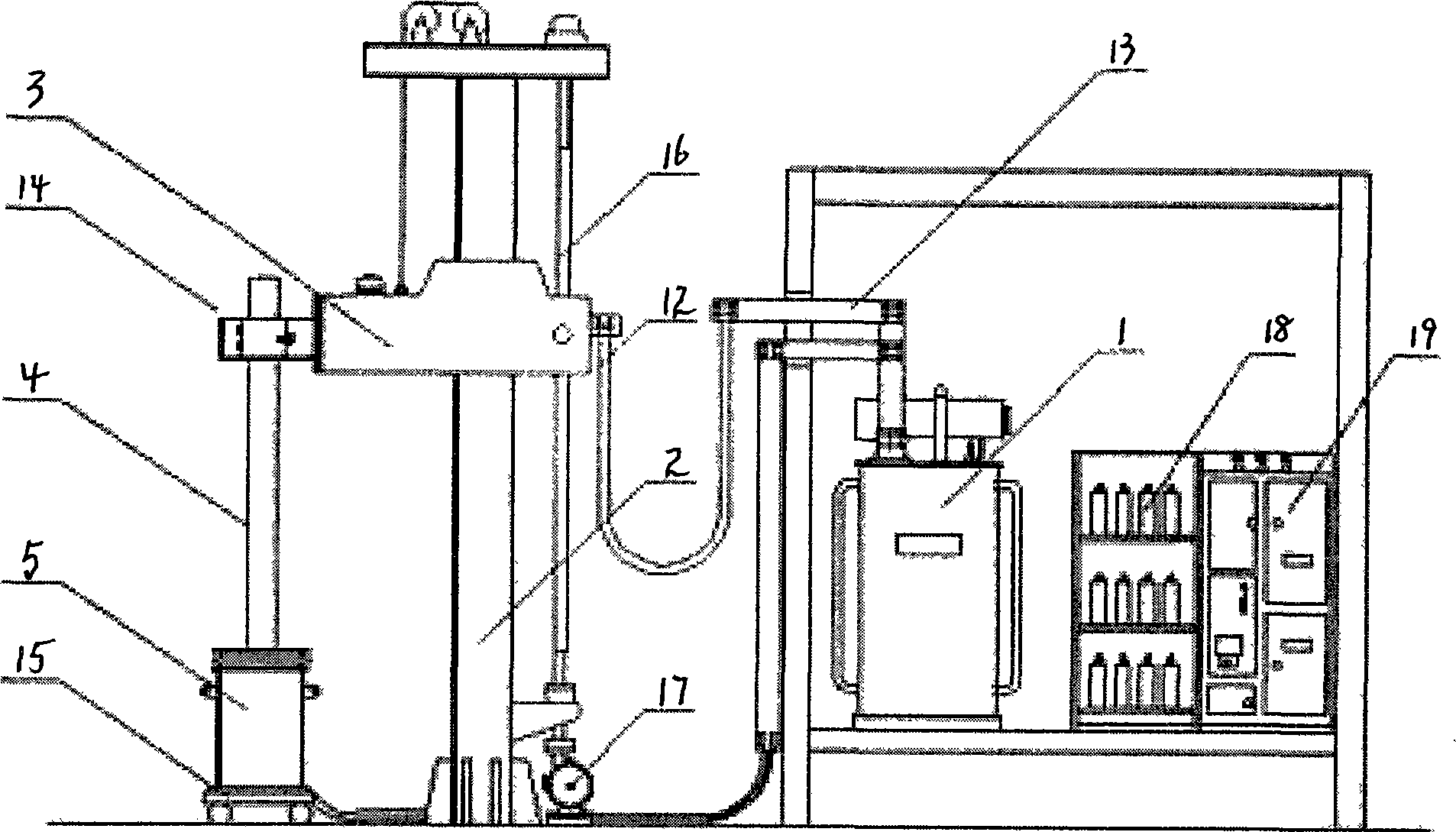

[0047] See figure 1 , The mold conductive, continuous casting type electroslag remelting furnace involved in the present invention is mainly composed of an ingot extraction system, a mold system, an electrode, an electrode lifting system, a power supply system, a control system, and cooling water.

[0048] The spindle pumping system is mainly composed of a spindle pumping column 7, a spindle pumping platform 8 and a bottom water tank 10. The spindle pumping platform 8 is sleeved on the spindle pumping column 7, and the bottom water tank 10 is installed on the spindle pumping platform 8.

[0049] The crystallizer system is mainly composed of a crystallizer platform 6 and a crystallizer 5. The crystallizer platform 6 is fixed on the top of the ingot pumping column 7, the crystallizer 5 is fixedly arranged on the crystallizer platform 6, and the crystallizer 5 is placed directly above the bottom water tank 10. The crystallizer 5 adopts a water-cooled barrel-type conductive crystalliz...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com