Method for preparing carbonaceous nano tube viscoelastic fluid

A carbon nanotube and viscoelasticity technology, applied in the field of new material preparation, can solve the problem of not being able to keep carbon nanotubes at the same time, achieve good stability and improve the effect of critical concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

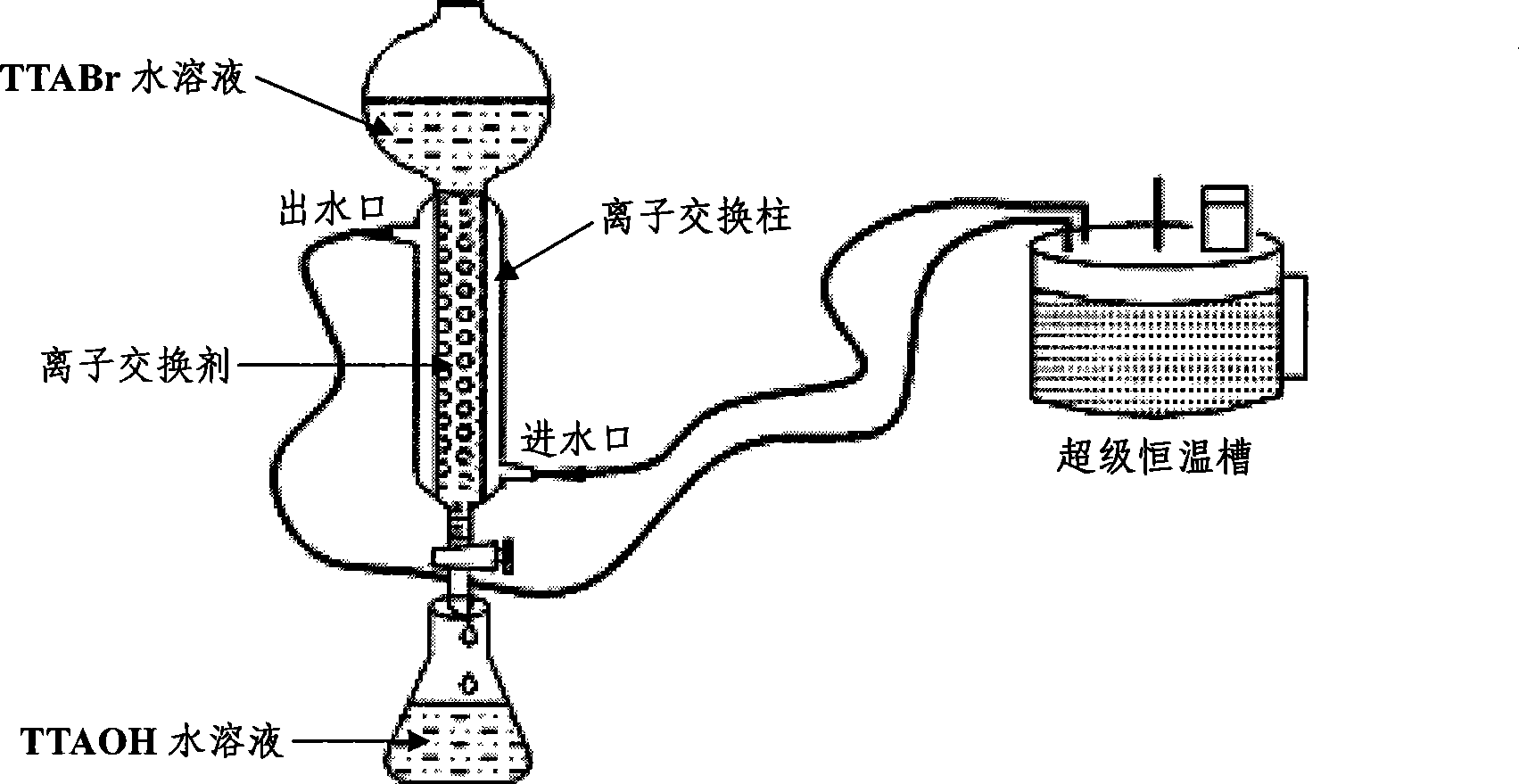

Method used

Image

Examples

Embodiment 1

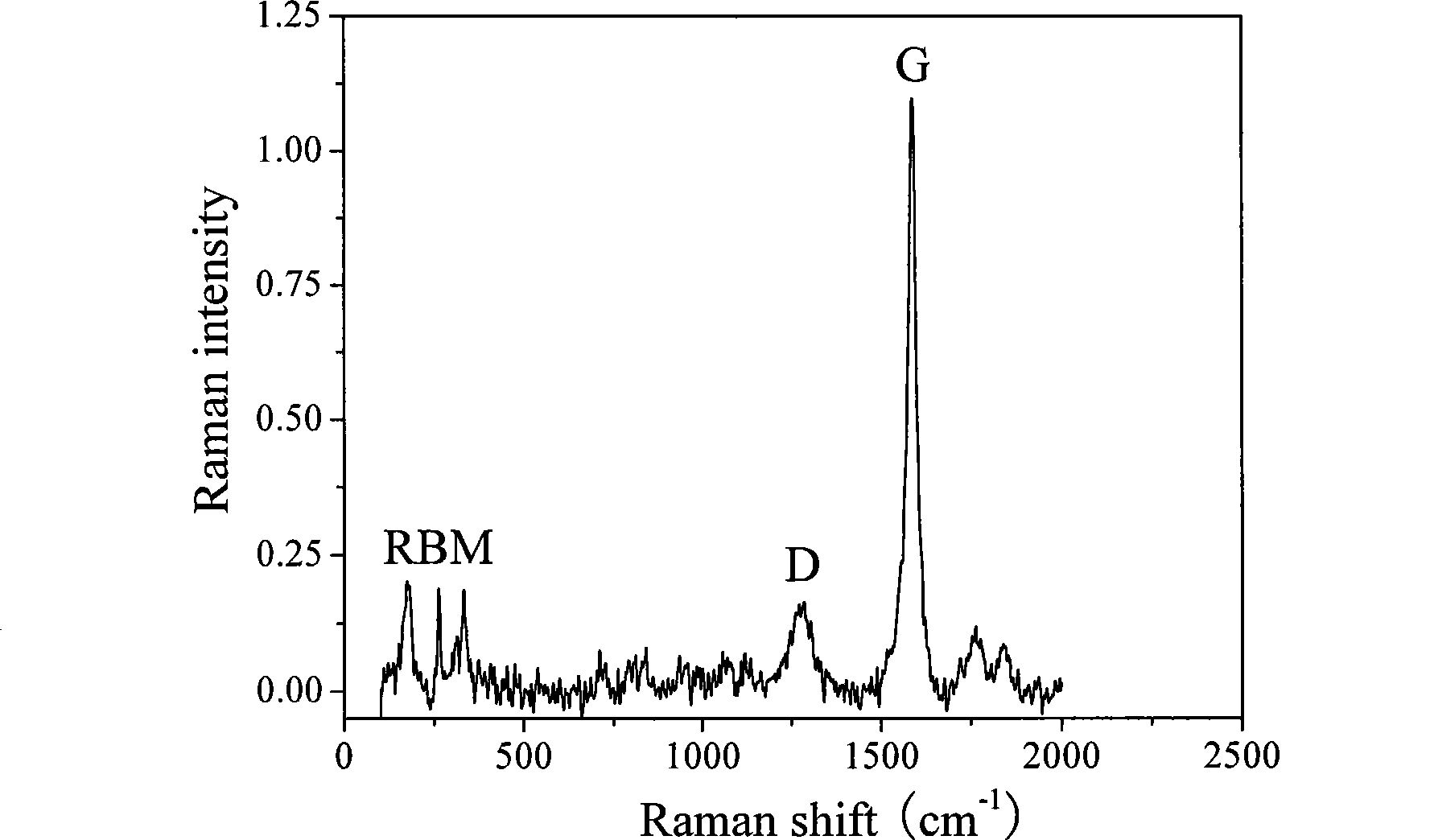

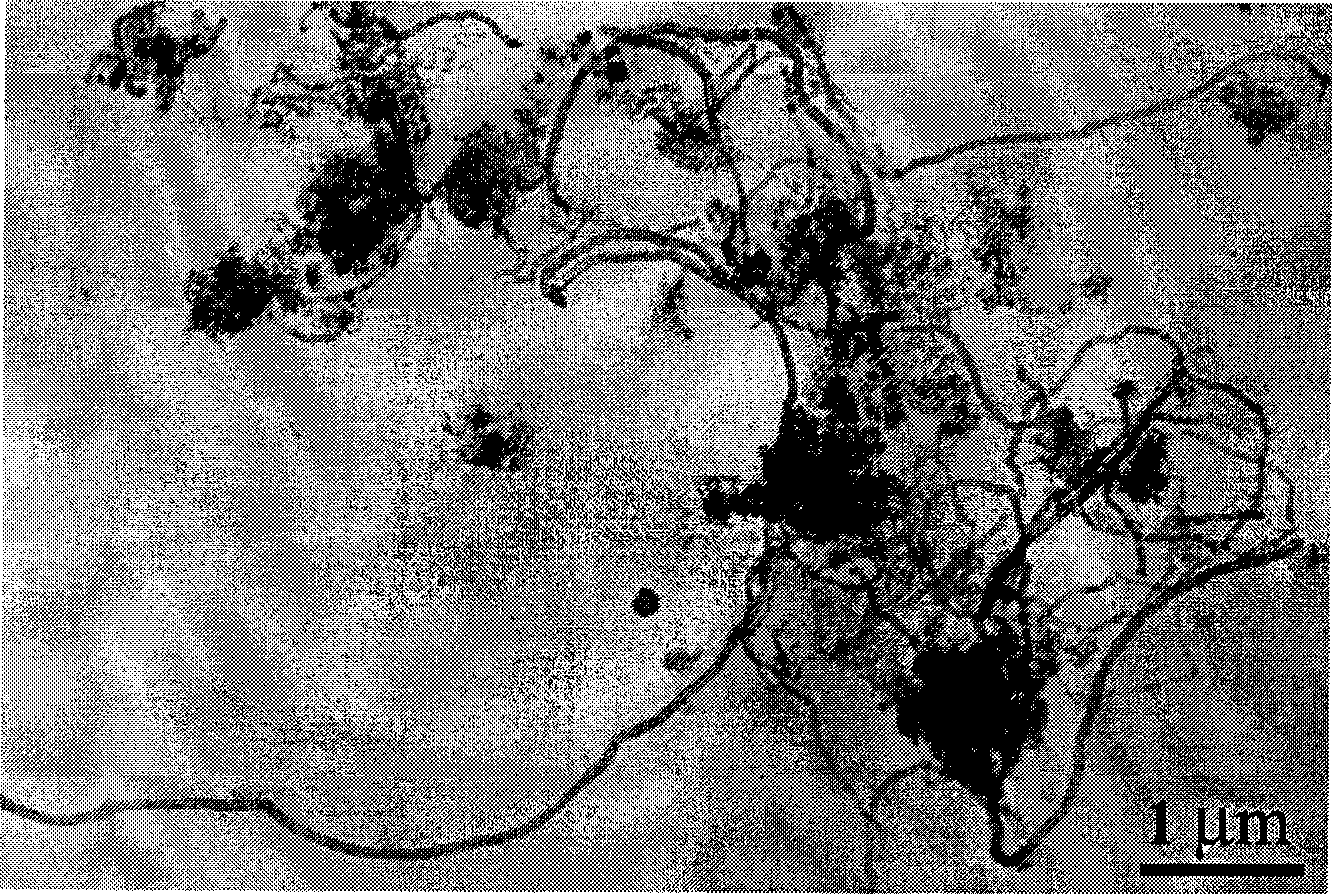

[0034] Embodiment 1: selected fatty acid is lauric acid (LA), and quaternary ammonium alkali cationic surfactant is tetradecyltrimethylammonium hydroxide (TTAOH), and the mol ratio of LA and TTAOH is 0.825, and surfactant total concentration The content of carbon nanotubes in the target sample is 0.8mg / mL, the content of polyvinylpyrrolidone is 10mg / mL, and the carbon nanotubes used are a mixture of single-walled and multi-walled carbon nanotubes, wherein the single-walled carbon nanotubes The tube content is about 50%, and the total content of impurities, including catalysts and amorphous carbon, etc., does not exceed 7%. Its Raman spectrum and transmission electron microscope photos are as follows figure 2 and image 3 shown.

Embodiment 2

[0035] Example 2: On the basis of Example 1, reduce the content of polyvinylpyrrolidone in the target sample, and adjust it to 8mg / mL, 6mg / mL, 4mg / mL and 2mg / mL in turn. With the decrease of polyvinylpyrrolidone content, the viscoelasticity of the mixed system is getting closer and closer to the situation without polyvinylpyrrolidone, such as Figure 4 and Figure 5 shown. However, the system still has a good ability to disperse carbon nanotubes. Sample photos and Raman spectra of typical samples are shown in Figure 6 and Figure 7 middle.

Embodiment 3

[0036] Example 3: On the basis of Example 1, increase the total concentration of surfactants in the target sample and adjust to 20mg / mL, 25mg / mL, 30mg / mL, 40mg / mL and 50mg / mL in turn.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com