Metal gravity casting automatic production line

An automatic production line and gravity casting technology, which is applied in foundry workshops, casting equipment, metal processing equipment, etc., can solve the problems of increased labor costs, production costs, inability to adapt to the development of enterprise production, and inability to significantly improve production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

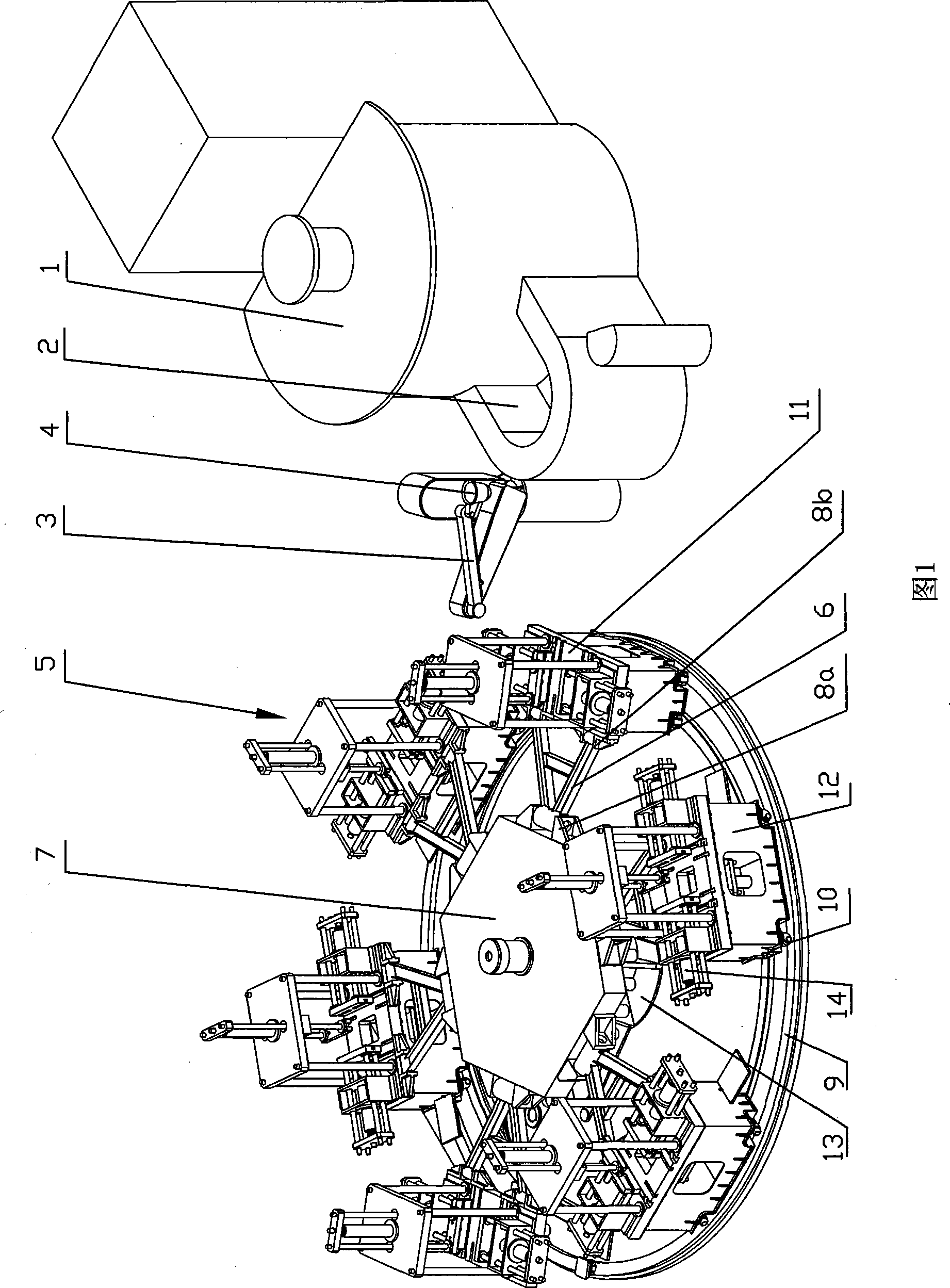

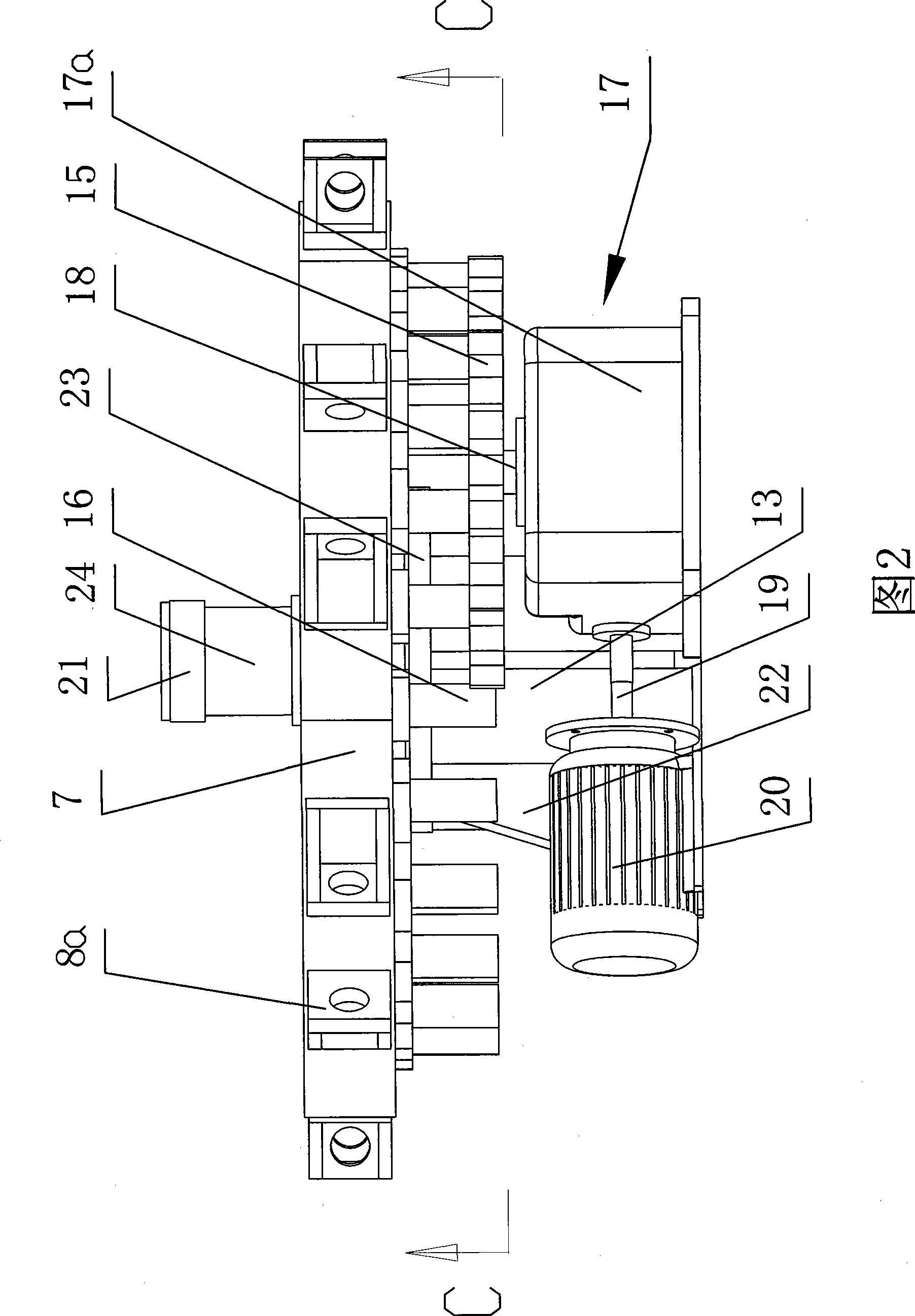

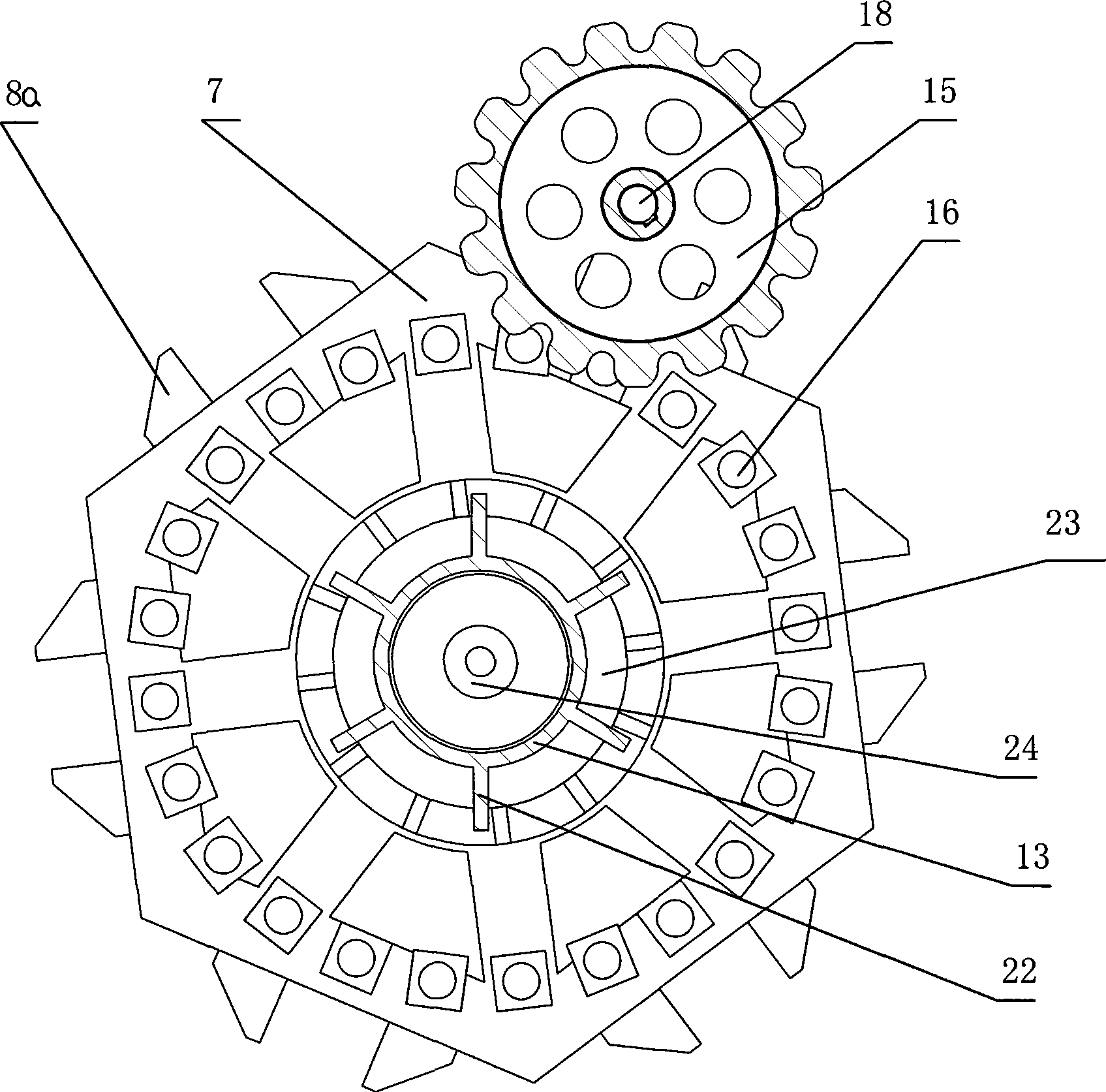

[0011] See Figure 1 to image 3 , an embodiment of an automatic production line for metal gravity casting, a circular orbit 9 is set on the ground, and a plurality of metal gravity casting machines 5 are placed on the circular orbit 9, and this embodiment is set as 6 metal gravity casting machines. Gravity casting machine 5, the frame 12 bottom of every metal gravity casting machine 5 is provided with four wheels 10 and contacts with track 9. The frame 12 of the metal gravity casting machine 5 is fixedly connected with a support 8b for installing the connecting arm, and the support 8b for installing the connecting arm is arranged on the frame 12 of the metal gravity casting machine 5 facing the circular surrounding One side of the center of the track 9 is located at the front and the rear of the frame 12 respectively. The two brackets 8b for installing the connecting arm are in a group, and there is a space for the connecting arm 6 to be inserted between the two brackets of ea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com