Acrylic acid macroscopic adsorptive resin for removing organic matter in solution and production method thereof

A technology of pore adsorption and acrylic acid, applied in chemical instruments and methods, other chemical processes, etc., can solve the problems of insignificant adsorption effect of macromolecular organic matter humic acid and fulvic acid, difficulty in removable ion exchange, loss of ion exchange function, etc. , to achieve good effluent water quality, high organic matter removal rate and good effluent repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

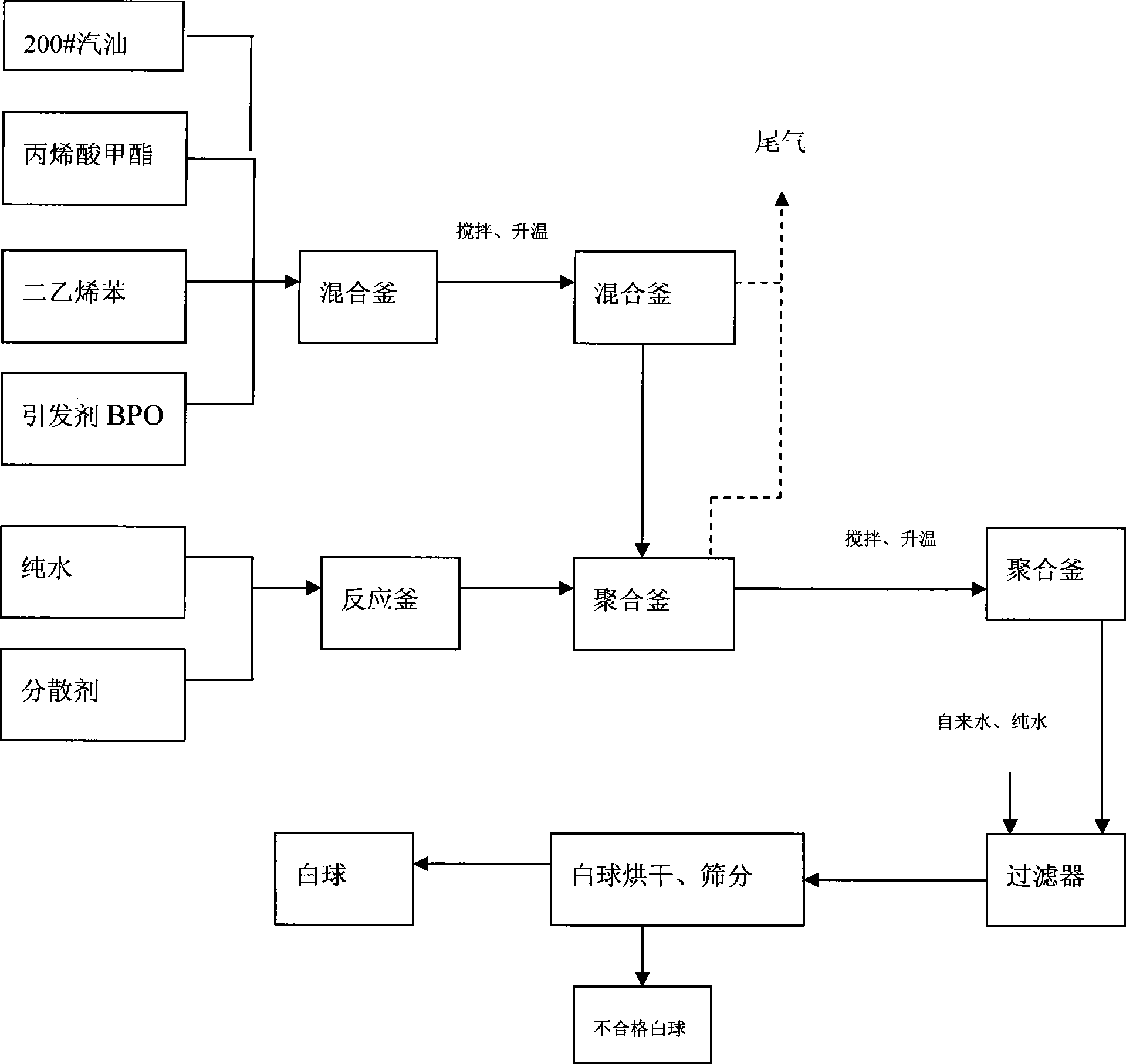

[0040] Embodiment 1: with reference to attached figure 1 . Method for producing acrylic macroporous adsorbent resin for removing organic matter in solution,

[0041] (1) Production process of acrylic white ball:

[0042]

[0043] Put 200# gasoline, methyl acrylate, divinylbenzene and initiator BPO into No. I mixing tank for stirring, raise the temperature to 40°C, put them into No. Put water and dispersant in the reaction kettle for mixing reaction, then put them into the polymerization kettle for polymerization reaction, react for 10 hours, the reaction produces white balls with different diameters, and after being washed with water, enter the filter for filtration, and dry the filtered white balls , sieve to get the desired white ball.

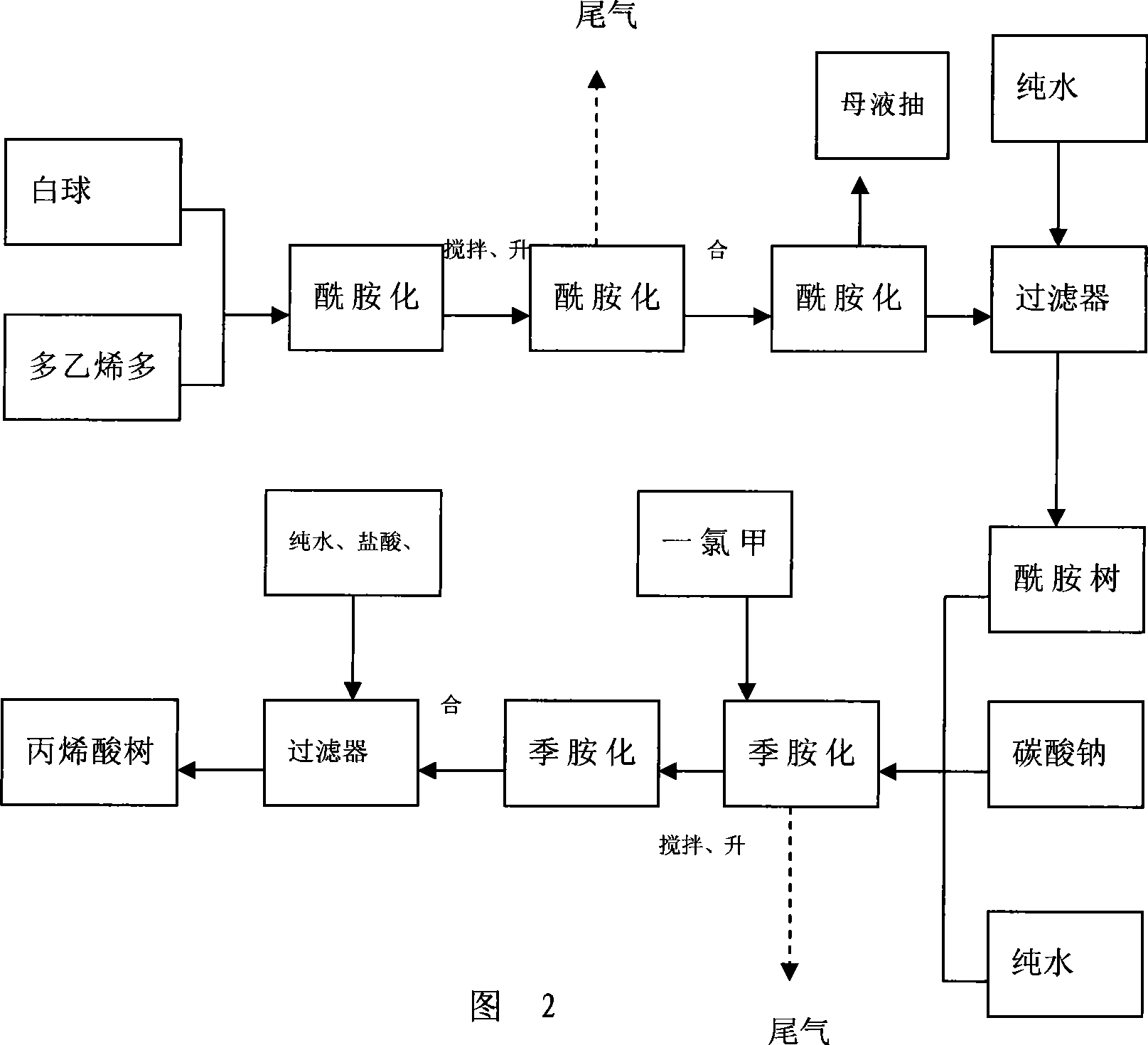

[0044] (2) Production process of acrylic macroporous adsorption resin:

[0045]

[0046] Put the white ball and polyethylene polyamine into the amidation kettle, stir, heat up to 100°C-165°C for 20 hours, discharge the tail gas, dr...

Embodiment 2

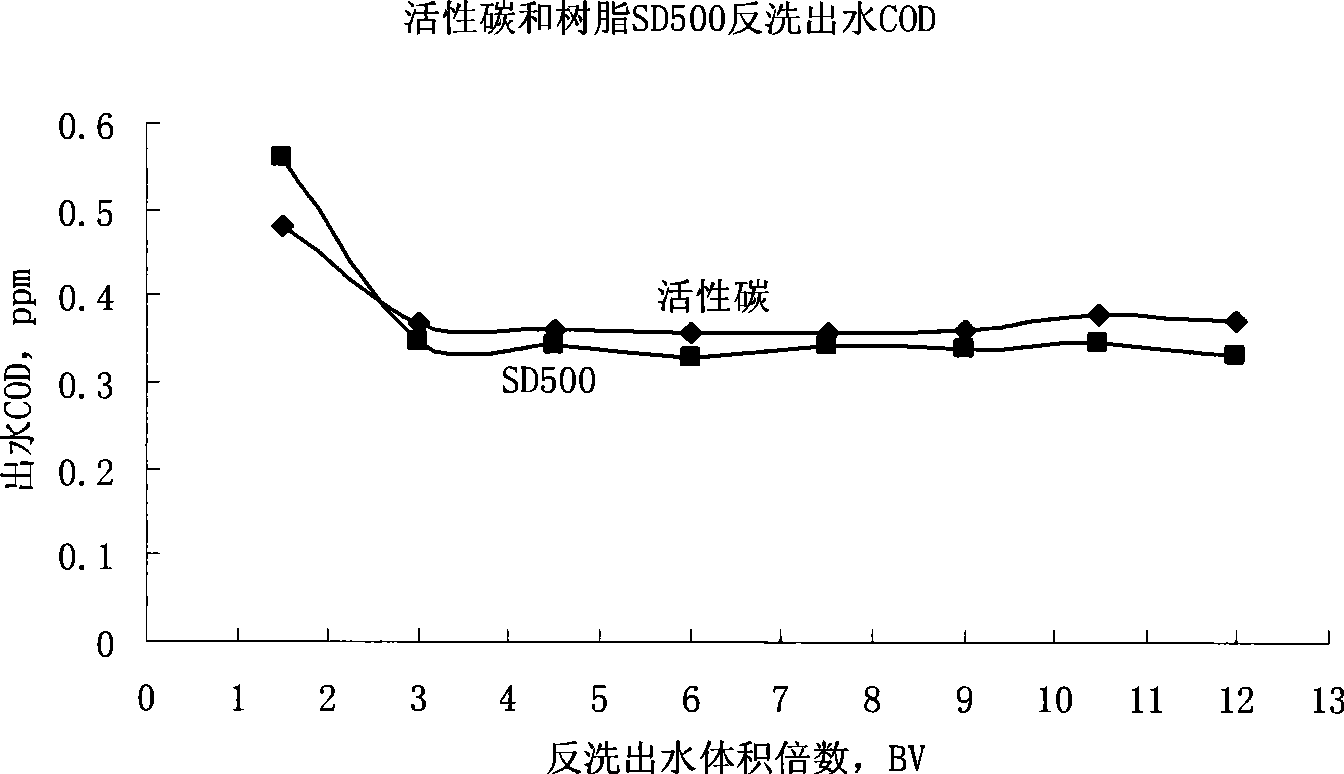

[0057] Embodiment 2: acrylic acid macroporous adsorption resin test comparison: the test device adopts two exchangers, wherein, the inner diameter of the exchanger is 37cm, and the height is 150cm; It is the clean water treated by the water station; the operation of the two exchangers adopts downstream operation, and the operating flow rate is 10m / h; the regeneration of the acrylic macroporous adsorption resin is downstream regeneration, the regeneration flow rate is 4m / h, and the amount of regenerant is 4BV; the determination method for organic matter is potassium permanganate method, the organic matter content of the influent water and the effluent water of activated carbon and acrylic macroporous adsorption resin are tested, and the regenerated effluent is tested, and the adsorption rate and adsorption capacity are calculated according to the test results , elution rate and periodic water production.

[0058] Outlet water quality testing:

[0059] 1. The determination meth...

Embodiment 3

[0077] Embodiment 3: the regeneration performance of acrylic acid macroporous adsorption resin:

[0078] 1. Different regeneration concentration tests: According to the previous test results, a flow rate of 20.4m / h was selected for different regeneration concentration tests. Regeneration test: Regeneration test with different concentrations of regeneration solutions (changing NaCl and NaOH concentrations). Divided into six groups of experiments, the six groups of experiments only have different regeneration conditions, and the other operating conditions are the same. The concentration of the regeneration agent in the six groups of experiments is as follows: (1) 2% NaCl+1% NaOH; (2) 2% NaCl+2% NaOH; (3) 4% NaCl+1% NaOH;

[0079] (4) 4% NaCl+2% NaOH; (5) 6% NaCl+1% NaOH; (6) 6% NaCl+2% NaOH;

[0080] The water in this test is tap water, and the conductivity of the tap water is 240-270μs / cm. Analyze the E of the resin in and out of the water every day 260 (Wavelength 254nm ul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com