Apparatus and method for on-line detecting welding part of strip

A detection method and measurement device technology, applied in the direction of measurement devices, welding equipment, analysis materials, etc., can solve the problems of short light source life, difficult installation of light detection system, dust or foreign matter pollution, etc., to improve production efficiency, and accuracy In-line detection and resolution of scratches and chipping effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings.

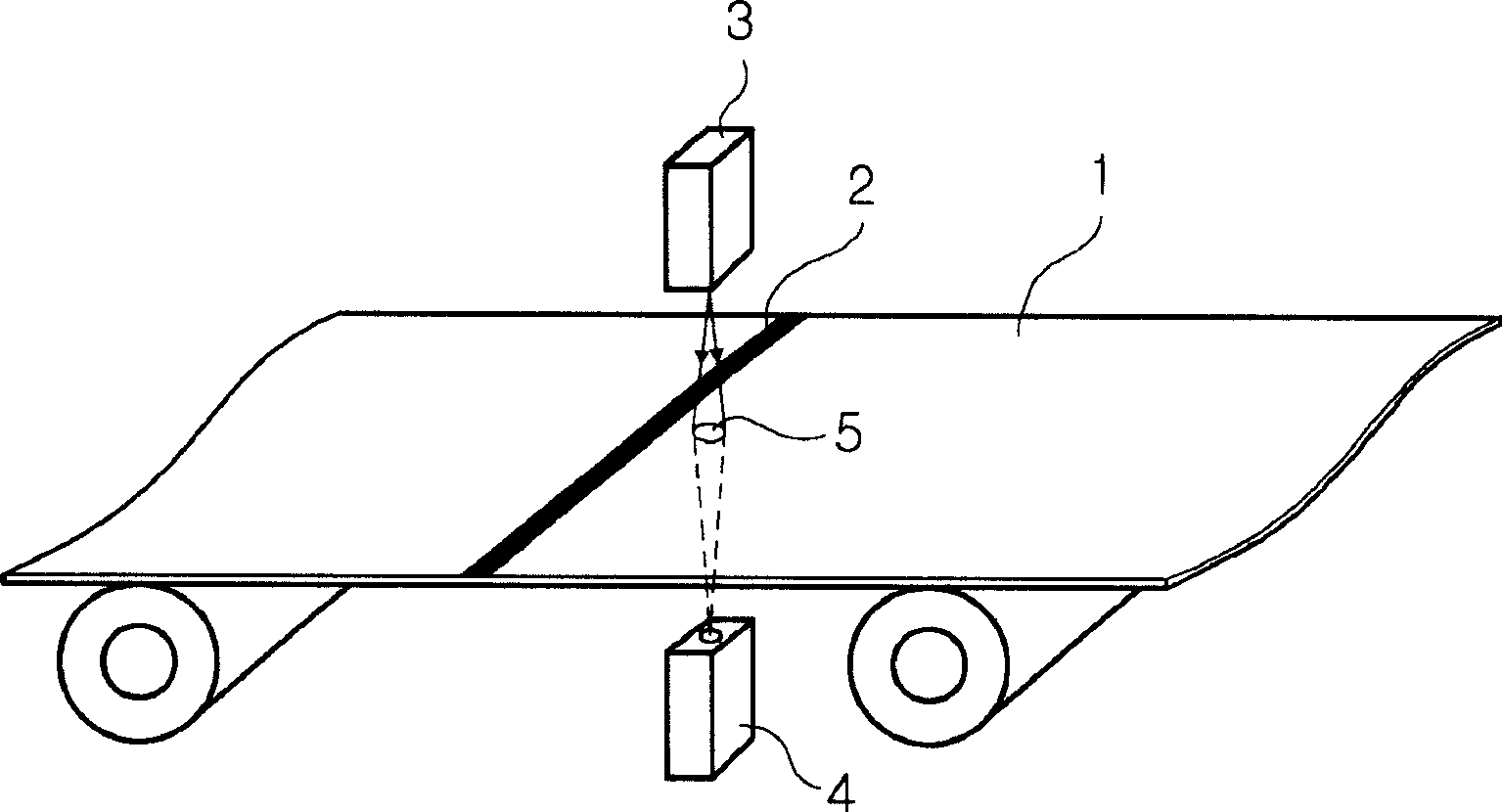

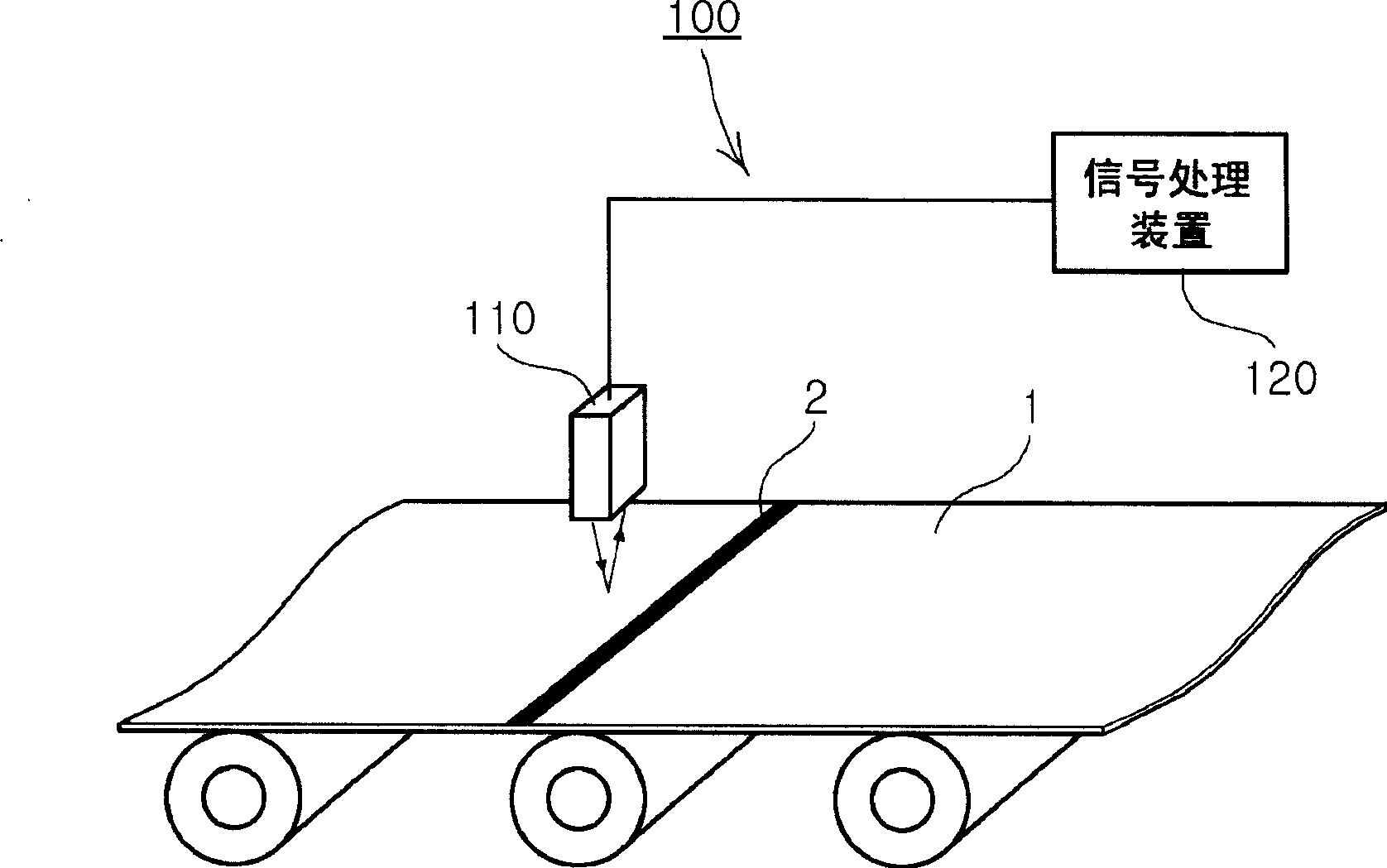

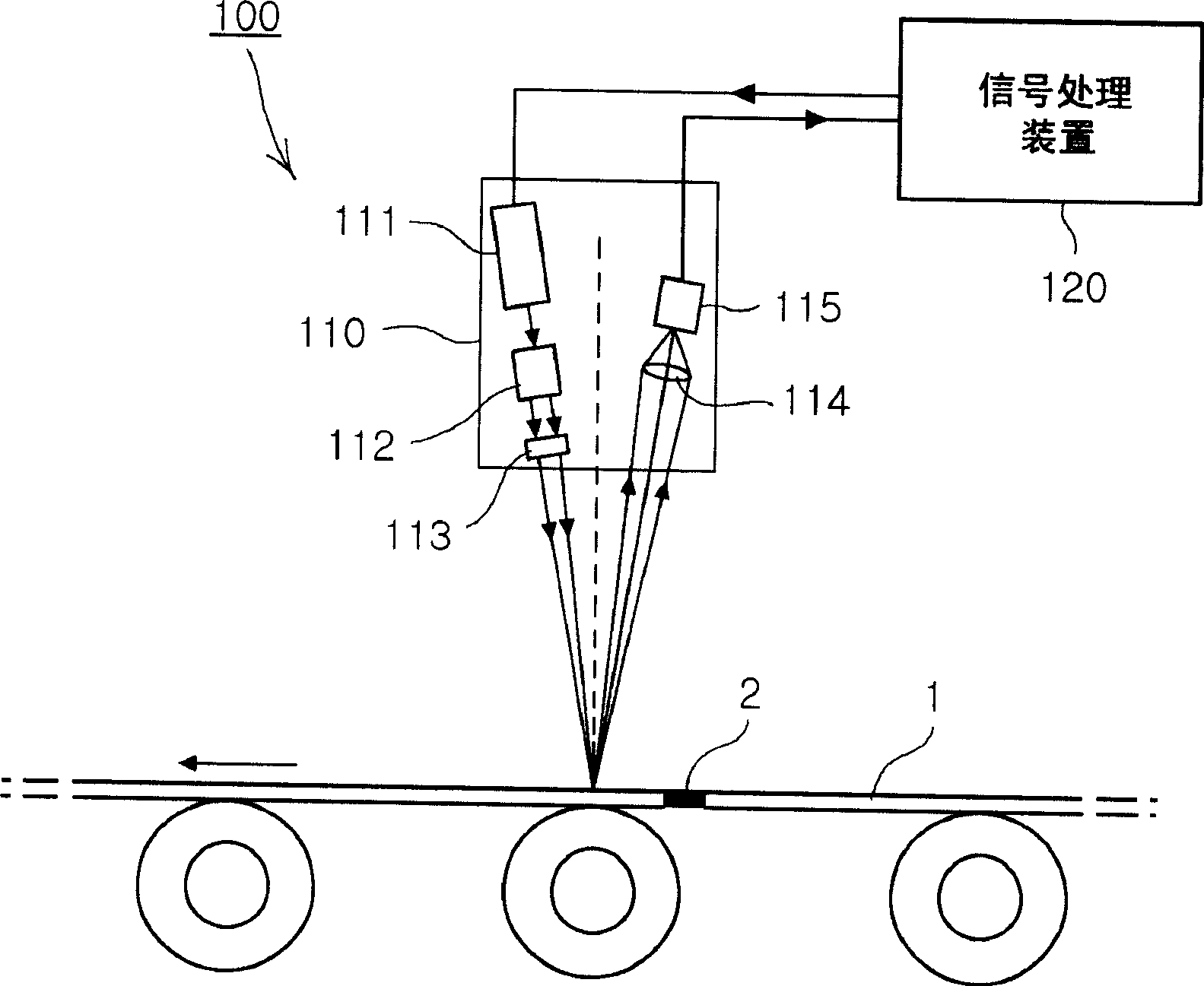

[0034] figure 2 The schematic diagram of the structure describes an online detection system for steel strip welds according to a specific embodiment of the present invention.

[0035] see figure 2 , the online detection system 100 for steel strip welds of the present invention includes a laser reflectance measurement device 110 and a signal processing device 120 . Although only one laser reflectance measuring device 110 is shown in the figure, this is only an exemplary embodiment of the present invention. In another specific embodiment of the present invention, two or more laser reflectance measuring devices may be provided according to the width of the steel strip 1 .

[0036] The laser reflectance measuring device continuously emits a laser beam onto the moving steel strip in conveyance, and continuously measures the reflectivity ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com