Long-duration encapsulated flavors and chewing gum using same

A technology of duration and flavoring agent, applied in the direction of chewing gum, food ingredients as encapsulants, food ingredients as odor improvers, etc., can solve complex and expensive problems, and achieve effective encapsulation, long-lasting fragrance, and low-cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

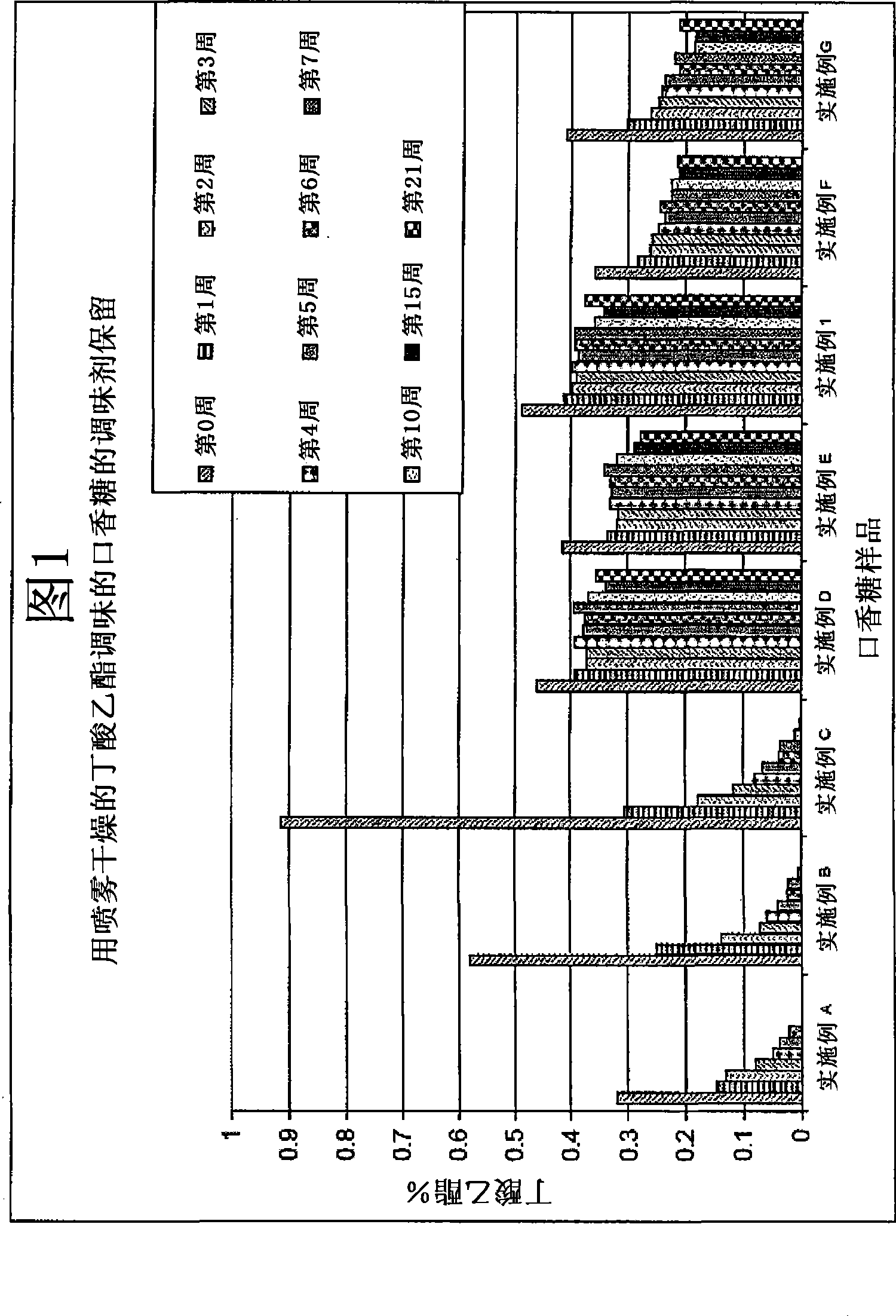

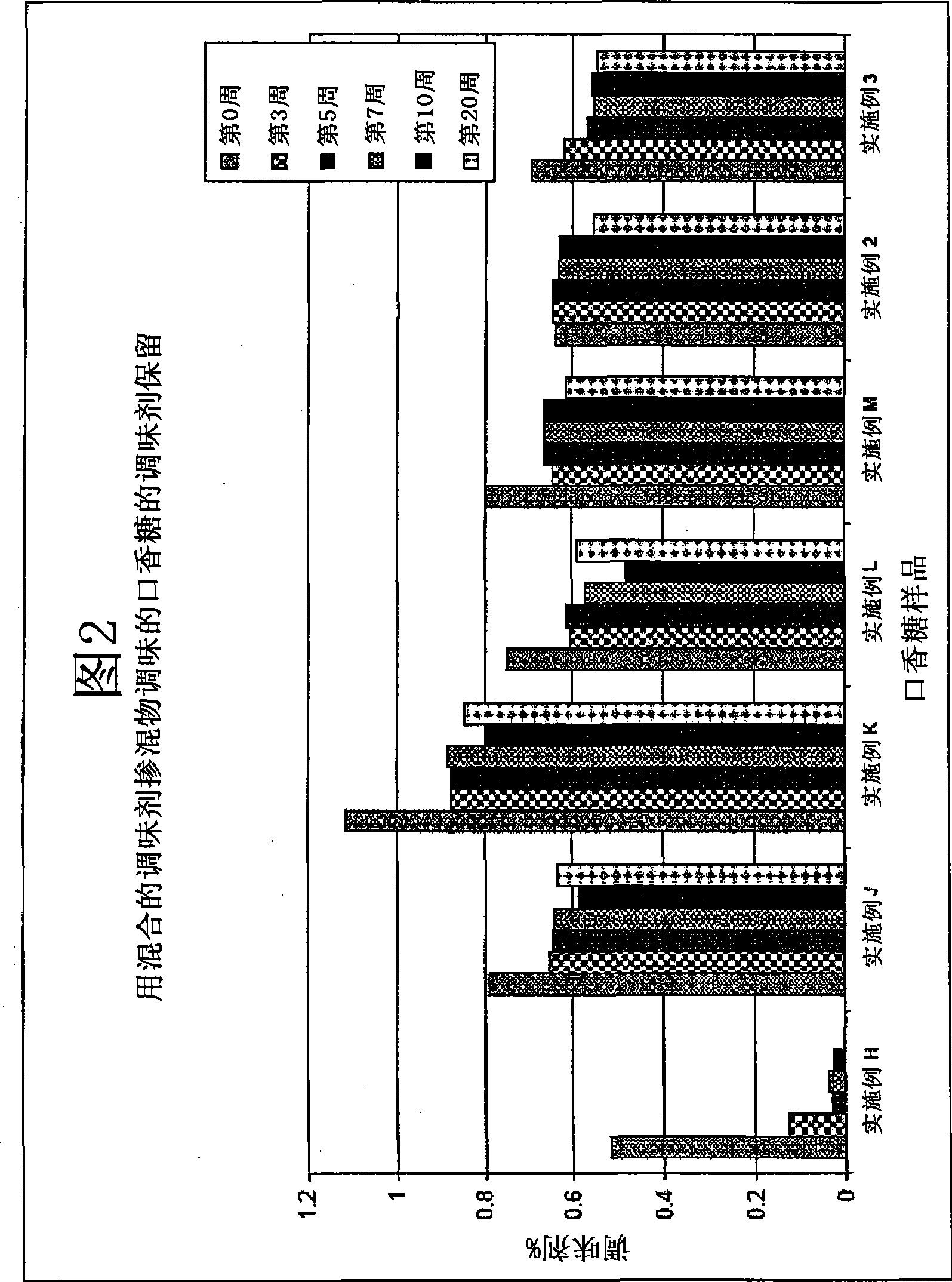

[0078] Example - Flavor Retention

[0079] The first step of the present invention is to create an encapsulated flavor that prevents the flavor from volatilizing and retains the flavor over time. One of the most common fruits is ethyl butyrate (pineapple flavoring). This material is used in various fruit flavor blends for chewing gum. Because it is very volatile, it will disappear from chewing gum formulations, which often changes the overall fruit flavor of the final product. By spray drying the ethyl butyrate, the flavor will remain in the chewing gum base for an extended period of time. However, it is very important to spray dry the encapsulant, since the flavor must be kept in the encapsulation matrix for as long as possible. Many standard encapsulants are not sufficiently effective at retaining volatile flavorants such as ethyl butyrate. Therefore, experiments were performed to determine the extent of ethyl butyrate loss in various encapsulants. A chewing gum composi...

Embodiment 5

[0154] Comparative Examples 5, 6, N, P and Q

[0155] Element (%) (%)

[0156] Sugar 57.42 48.23

[0157] Gum base 19.30 19.30

[0158] Corn syrup (39 DE, 45.5 Be) 13.91 13.91

[0159] Dextrose 7.28 7.28

[0160] Glycerin 1.15 1.15

[0161] Liquid flavoring 0.81 -

[0162] Encapsulated Flavor - 10.00

[0163] Lecithin 0.13 0.13

[0164] Sensory evaluation

[0165] Flavor loading was determined by gas chromatography. The control sample flavored with liquid fruit flavor had a flavor loading of about 0.63% by weight of the chewing gum. The flavor loading of the chewing gum using the long duration flavor material of the present invention described above was about 0.69%.

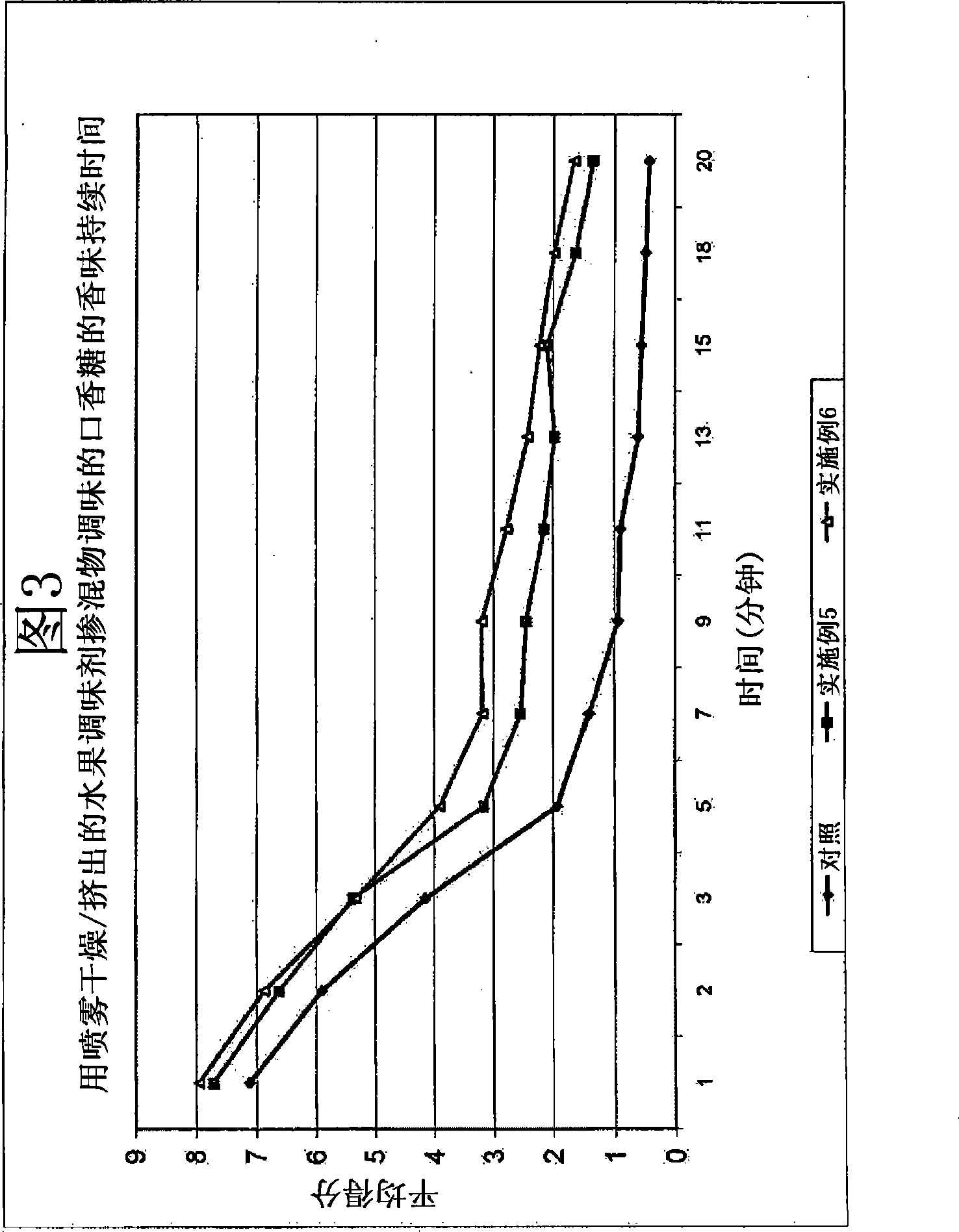

[0166] Control, Example 5 (100 μ average particle size), Example 6 (1000 μ average particle size) and two other samples (Comparative Examples N and P) were evaluated using the 20 minute time-intensity metho...

Embodiment 6

[0169] Control Example 5 Example 6 Comparative Example N Comparative Example P

[0170] 100μ 1000μ 1000μ 1000μ

[0171] 1 minute 7.12 7.72 7.96 7.35 7.61

[0172] 2 minutes 5.91 6.63 6.88 6.33 6.20

[0173] 3 minutes 4.14 5.38 5.34 4.97 4.33

[0174] 5 minutes 1.93 3.16 3.90 3.21 2.46

[0175] 7 minutes 1.41 2.54 3.18 2.59 1.74

[0176] 9 minutes 0.94 2.45 3.19 2.04 1.54

[0177] 11 minutes 0.90 2.15 2.77 1.92 1.41

[0178] 13 minutes 0.60 1.97 2.42 1.65 1.19

[0179] 15 minutes 0.55 2.09 2.22 1.70 1.18

[0180] 18 minutes 0.48 1.62 1.98 1.45 0.99

[0181] 20 minutes 0.43 1.35 1.65 1.11 0.84

[0182] Table 6

[0183] sweetness duration

[0184] Control Example 5 Example 6 Comparative Example N Comparative Example P

[0185] 100μ 1000μ 1000μ 1000μ

[0186] 1 minute 8.32 8.79 9.53 8.55 8.75

[0187] 2 minutes 6.54 7.84 8.38 7.33 7.26

[0188] 3 minutes 4.71 6.25 6.67 5.77 5.01

[0189] 4 minutes 3.22 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com