System and method for managing roller

A management system and management method technology, applied in the control field of rolled steel products, can solve the problems of inability to collect from the site, poor roll information, and less data processing, and achieve the effect of a good authority management mechanism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

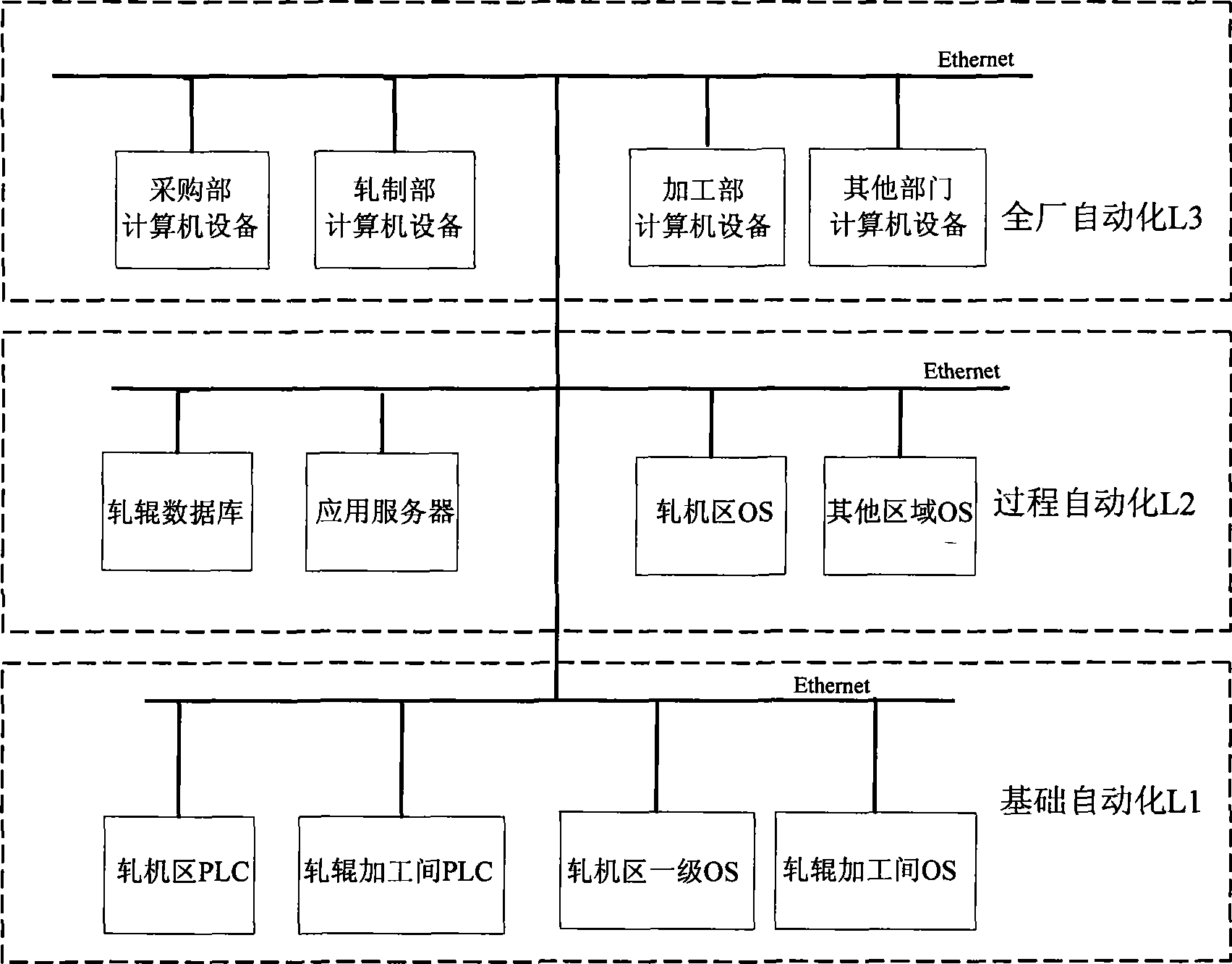

[0043] At first, explain the basis of the present invention:

[0044] The departments that use this system in the rolling mill mainly include purchasing department, processing department and rolling department. The main responsibilities of these departments are as follows:

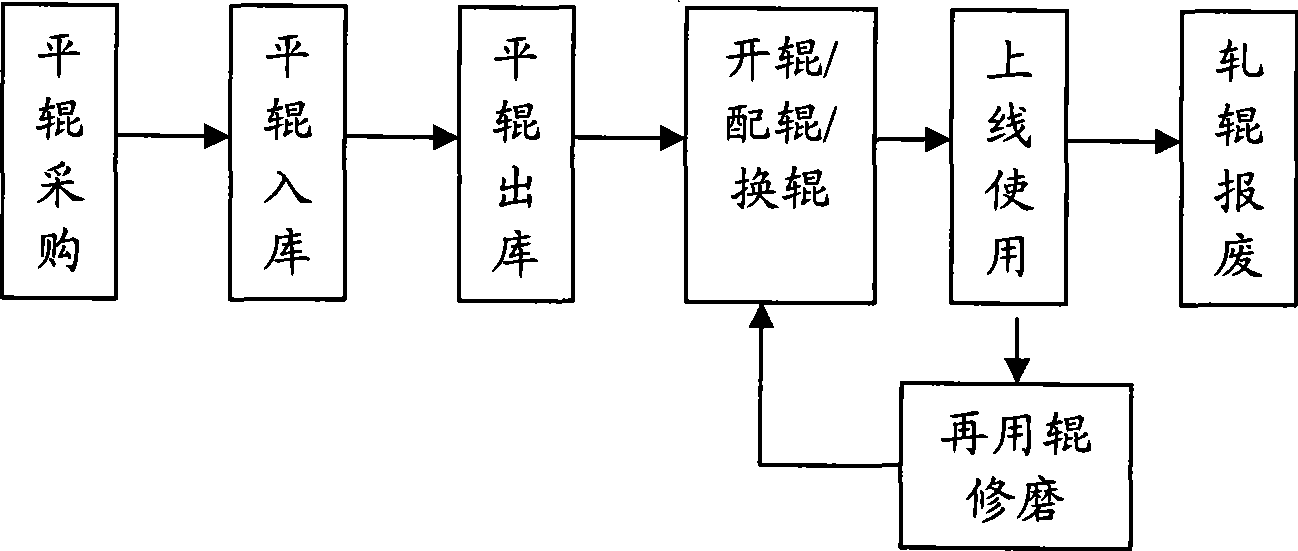

[0045] 1) Purchasing Department: mainly responsible for the summary and compilation of roll purchase plans, ordering, and storage of flat rolls;

[0046] 2) Processing Department: Responsible for inventory management of flat rolls such as roll opening, storage, and delivery, as well as regrinding of reused rolls;

[0047] 3) Rolling Department: Submit the flat roll order plan, be responsible for the roll configuration, use, and roll replacement of the rolls, and record the relevant information of the rolls during use.

[0048] Depending on the management model of the enterprise, the composition and functions of the above departments may be different.

[0049] The second step describes the system of the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com