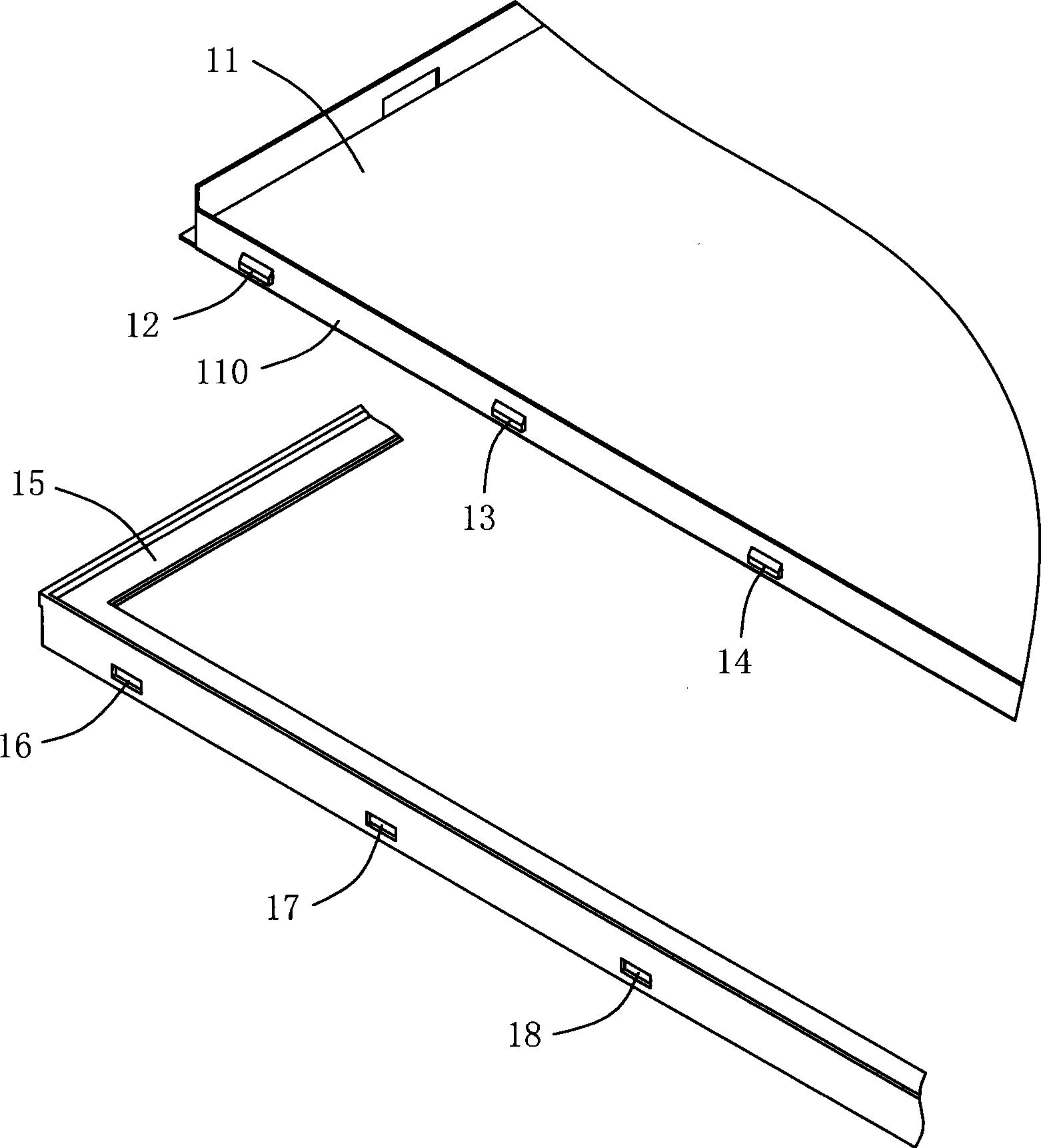

Outer frame of backlight module unit

A backlight module and frame technology, applied in optics, nonlinear optics, instruments, etc., can solve the problems of increased manufacturing costs, operator fatigue, collision and scratches, etc., to reduce the difficulty of disassembly and assembly, and improve the disassembly and assembly. Speed, the effect of reducing operation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The directional terms mentioned in the following embodiments, such as: up, down, left, right, front or back, etc., are only directions referring to the attached drawings. Accordingly, the directional terms are used to illustrate and not to limit the invention.

[0016] Please refer to FIG. 2 and FIG. 3, according to a preferred embodiment of the present invention, it provides an outer frame of a detachable backlight module, the outer frame includes an upper frame 20 and a back plate 21, with corresponding The shapes and sizes can be combined with each other to form the frame of the backlight module.

[0017] The upper frame 20 can be made of appropriate material and has an appropriate shape. In this embodiment, the upper frame 20 is made of plastic material. In this embodiment, the upper frame 20 is rectangular and has a first upper frame side 201, two second upper frame sides 202 and two pivot portions 26, wherein the two second upper frame sides 202 are parallel to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com