Two-phase integral column as well as preparation and application thereof

A monolithic column and monolithic material technology, applied in other chemical processes, chemical instruments and methods, material separation, etc., to achieve the effects of easy fabrication, increased column length, and efficient separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

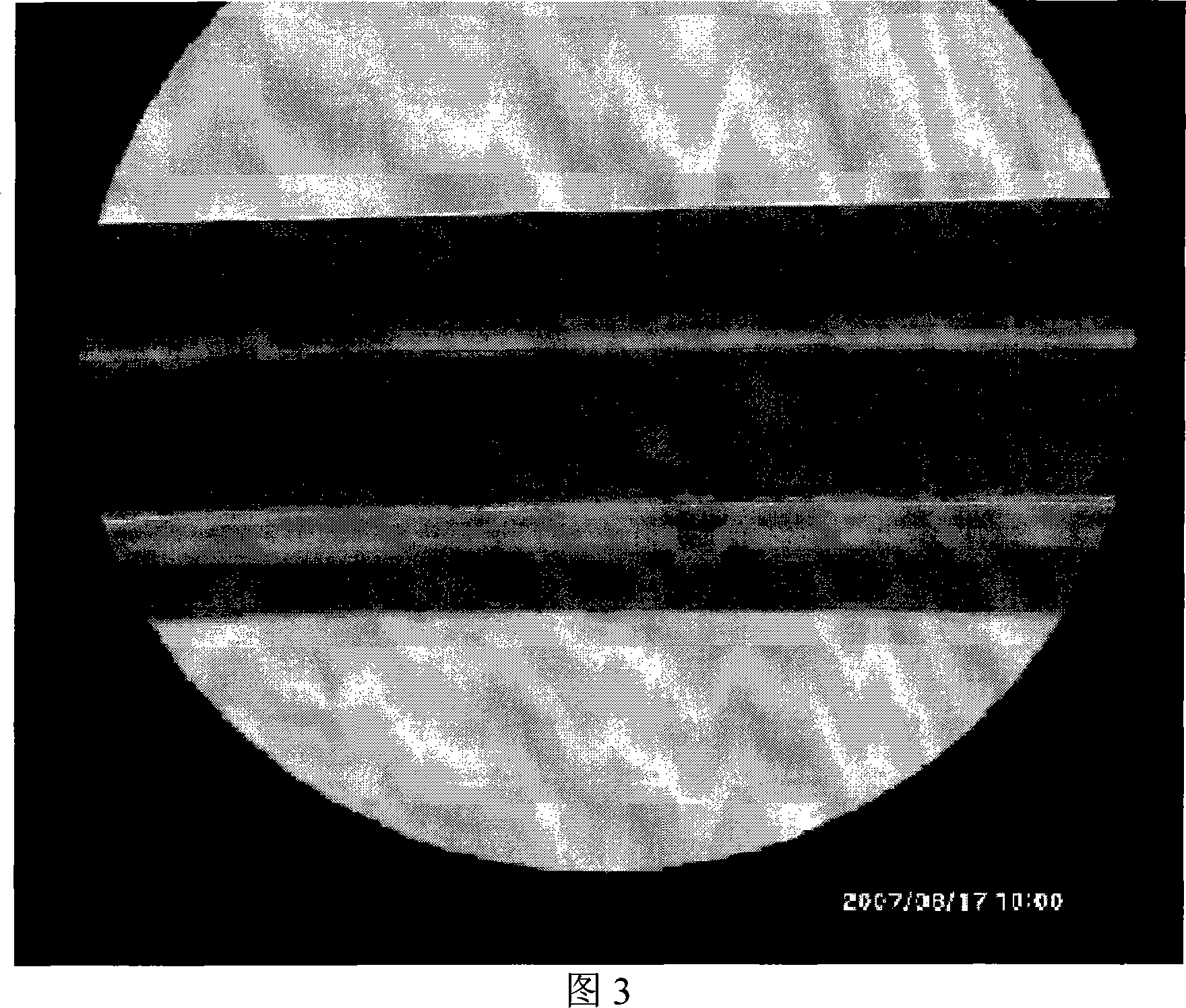

[0023] 1. Preparation of two-phase capillary monolithic column

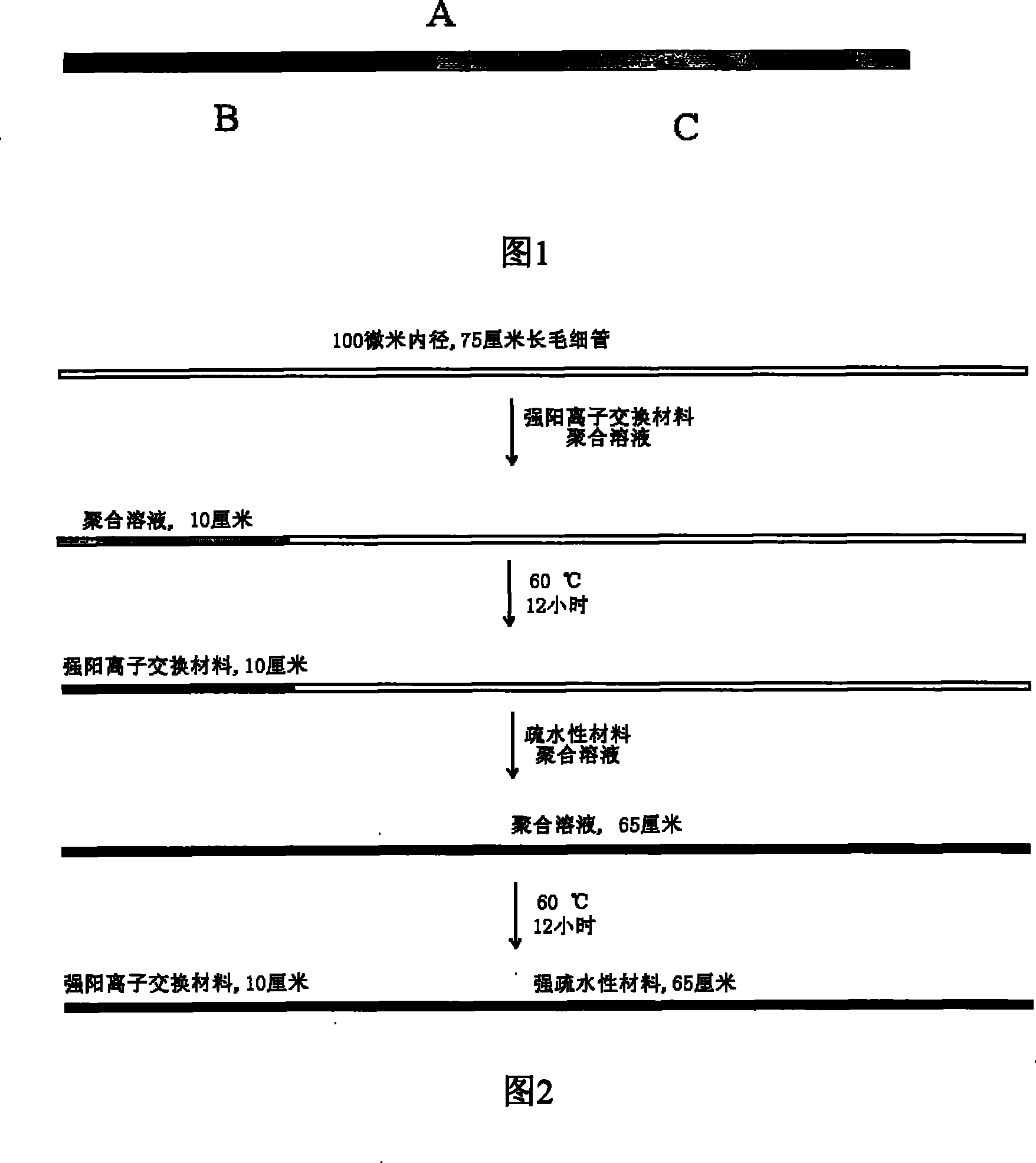

[0024] Such as figure 2 As shown, a 10 cm long strong cation exchange material and a 65 cm long strong hydrophobic material were successively synthesized in a capillary with an inner diameter of 100 microns and a length of 75 cm.

[0025] 1. Capillary Pretreatment

[0026] First wash the capillary empty column with 0.1M NaOH solution for 1h, then rinse the capillary with deionized water until the pH of the effluent liquid is 7.0, then rinse the capillary with 0.1M HCl solution for 4h, and then rinse the capillary with deionized water until the pH of the effluent liquid is 7.0, then rinse the capillary column with methanol solution for 10 min, and dry it with nitrogen. A mixture of methanol and methacryloxypropyl-trimethoxysilane was injected into the capillary. React at a temperature of 20°C to 70°C for 5-24 hours. Then rinse with methanol and water. Finally, dry it with nitrogen gas.

[0027] 2. Synthesis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com