Turbine type flow sensor for oil field well cementing

A flow sensor and turbine-type technology, applied in the field of flow sensors, can solve problems such as measurement errors and affecting cementing quality, and achieve the effects of small measurement errors, ensuring cementing quality, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

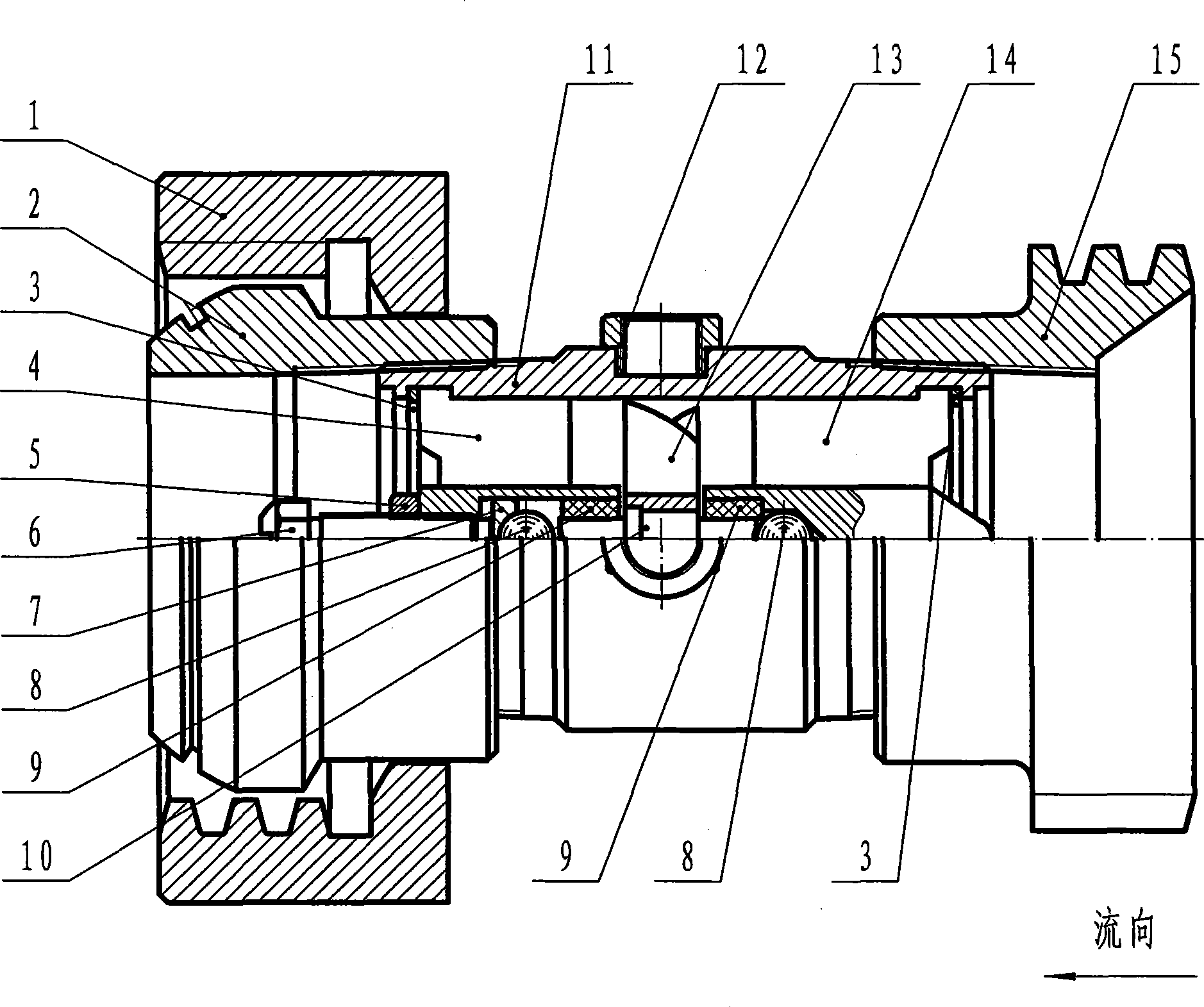

[0013] A turbine-type flow sensor for oil field cementing, consisting of a body 11, a shaft-through turbine assembly, an inlet guide frame 14, an outlet guide frame 4, an inlet joint and an outlet joint; the body 11 is a cylindrical metal tube The shaft-through turbine assembly includes a turbine 13, a turbine shaft 10, a shaft sleeve 9, a steel ball 8, a steel ball pad 7, an adjusting bolt 6, a spring retainer ring 3 and a lock nut 5, and the turbine 13 is fixed to the turbine shaft 10, two The bushings 9 are located on both sides of the turbine 13 and are closely matched with the inner holes of the inlet and outlet guide frames 14 and 4 respectively. Two steel balls 8 are respectively located at the two ends of the turbine shaft 10 and limit the turbine shaft 10. The steel ball 8 on the side is positioned by the round hole on the inlet guide frame 14, the steel ball 8 on the outlet side is located in the round hole of the outlet guide frame 4 and the position of the steel bal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com