Al-Zn-Mg-Cu-Zr-Er alloy

A technology of alloys and rare earths, which is applied in the field of alloys, can solve problems such as the influence of alloy properties that have not been reported in any reports, and achieve the effect of increasing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

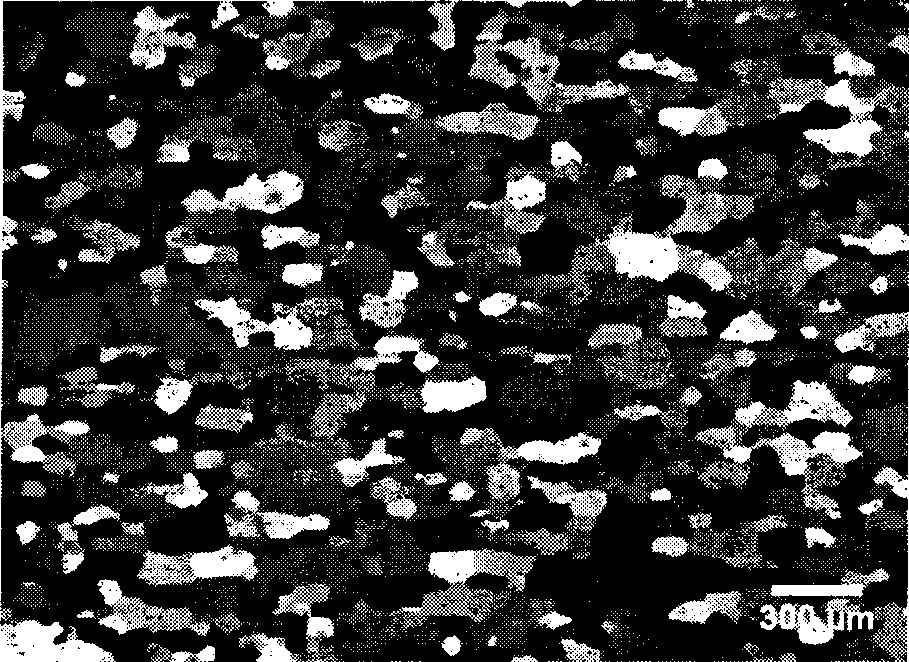

Embodiment 1

[0026] Firstly, pure Zn, pure Mg, Al-50Cu master alloy, Al-10Zr master alloy and high-purity aluminum ingot (purity up to 99.99%) are used as raw materials;

[0027] Use commercially available refining agents and slag removers for degassing and slag removal, and melt aluminum with a composition of 5.7-6.9% Zn-1.9-2.7% Mg-1.9-2.6% Cu-0.08-0.15% Zr in a crucible resistance furnace Alloy ingots, after ingot sampling, after uniform annealing at 470°C / 24h, cut the head and tail and mill the surface, heat through (380°C-430°C / 2-3h) and then hot-roll, the final thickness of the hot-rolled plate is 4mm, The total deformation is up to 90%. After the hot-rolled plate is solution treated at 470°C / 1h, it is subjected to aging heat treatment at 100°C to 150°C for different times, and various properties are measured.

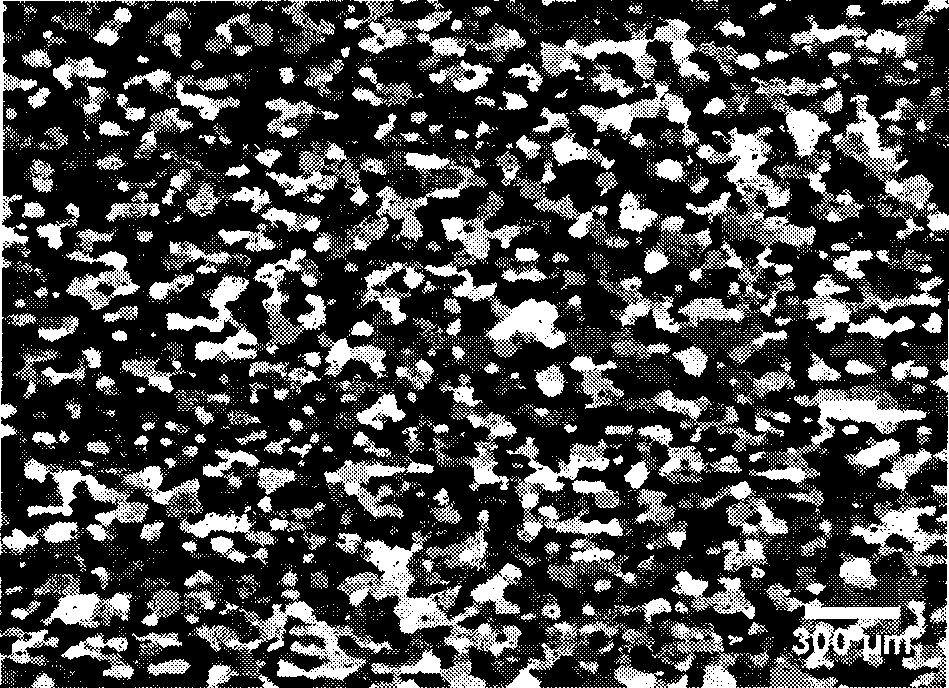

Embodiment 2

[0029] Using pure Zn, pure Mg, Al-50Cu master alloy, Al-10Zr master alloy, Al-10Er master alloy and high-purity aluminum ingot (purity up to 99.99%) as raw materials;

[0030] Use commercially available refining agents and slag removers for degassing and slag removal, and melt in a crucible resistance furnace with a composition of 5.7-6.9% Zn-1.9-2.7% Mg-1.9-2.6% Cu-0.08-0.15% Zr-0.1 %Er aluminum alloy ingot, after ingot sampling, after uniform annealing at 470°C / 24h, cut head and tail and face milling, heat through (380°C-430°C / 2-3h) and then hot-roll, and finally hot-rolled plate The thickness is 4mm, and the total deformation reaches 90%. After the hot-rolled plate is solution treated at 470°C / 1h, it is subjected to aging heat treatment at 100°C to 150°C for different times, and various properties are measured.

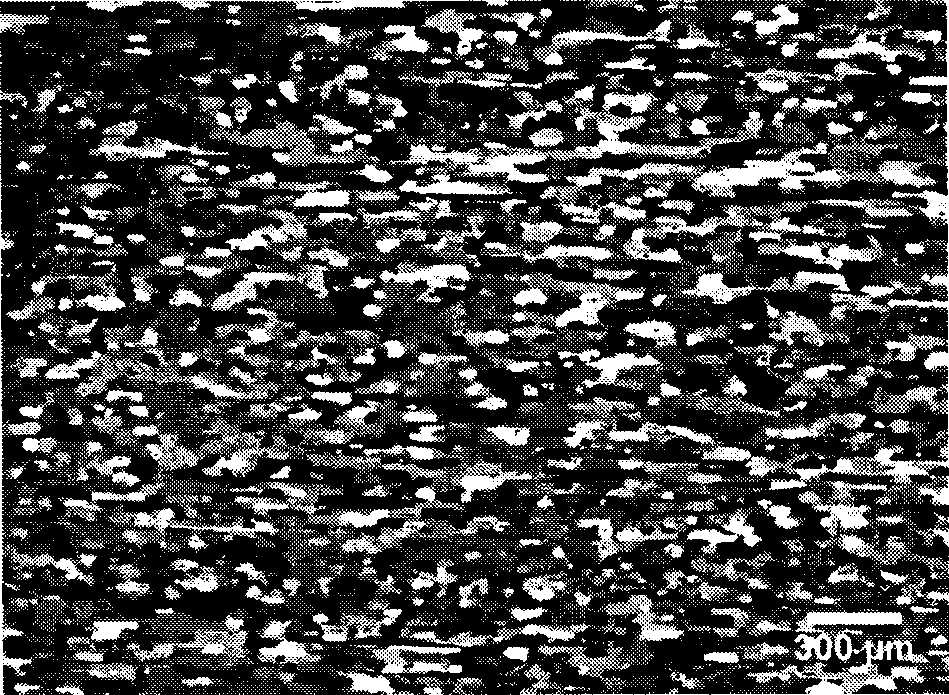

Embodiment 3

[0032] Using pure Zn, pure Mg, Al-50Cu master alloy, Al-10Zr master alloy, Al-10Er master alloy and high-purity aluminum ingot (purity up to 99.99%) as raw materials;

[0033] Use commercially available refining agents and slag removers for degassing and slag removal, and melt in a crucible resistance furnace with a composition of 5.7-6.9% Zn-1.9-2.7% Mg-1.9-2.6% Cu-0.08-0.15% Zr-0.3 %Er aluminum alloy ingot, after ingot sampling, after uniform annealing at 470°C / 24h, cut head and tail and face milling, heat through (380°C-430°C / 2-3h) and then hot-roll, and finally hot-rolled plate The thickness is 4mm, and the total deformation reaches 90%. After the hot-rolled plate is solution treated at 470°C / 1h, it is subjected to aging heat treatment at 100°C to 150°C for different times, and various properties are measured.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com