Full-automatic spot welding machine

A spot welding machine, fully automatic technology, applied in welding equipment, welding equipment, resistance welding equipment and other directions, can solve the problems of high labor cost, low work efficiency, different welding points, etc., to reduce production costs and improve points The effect of welding quality and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

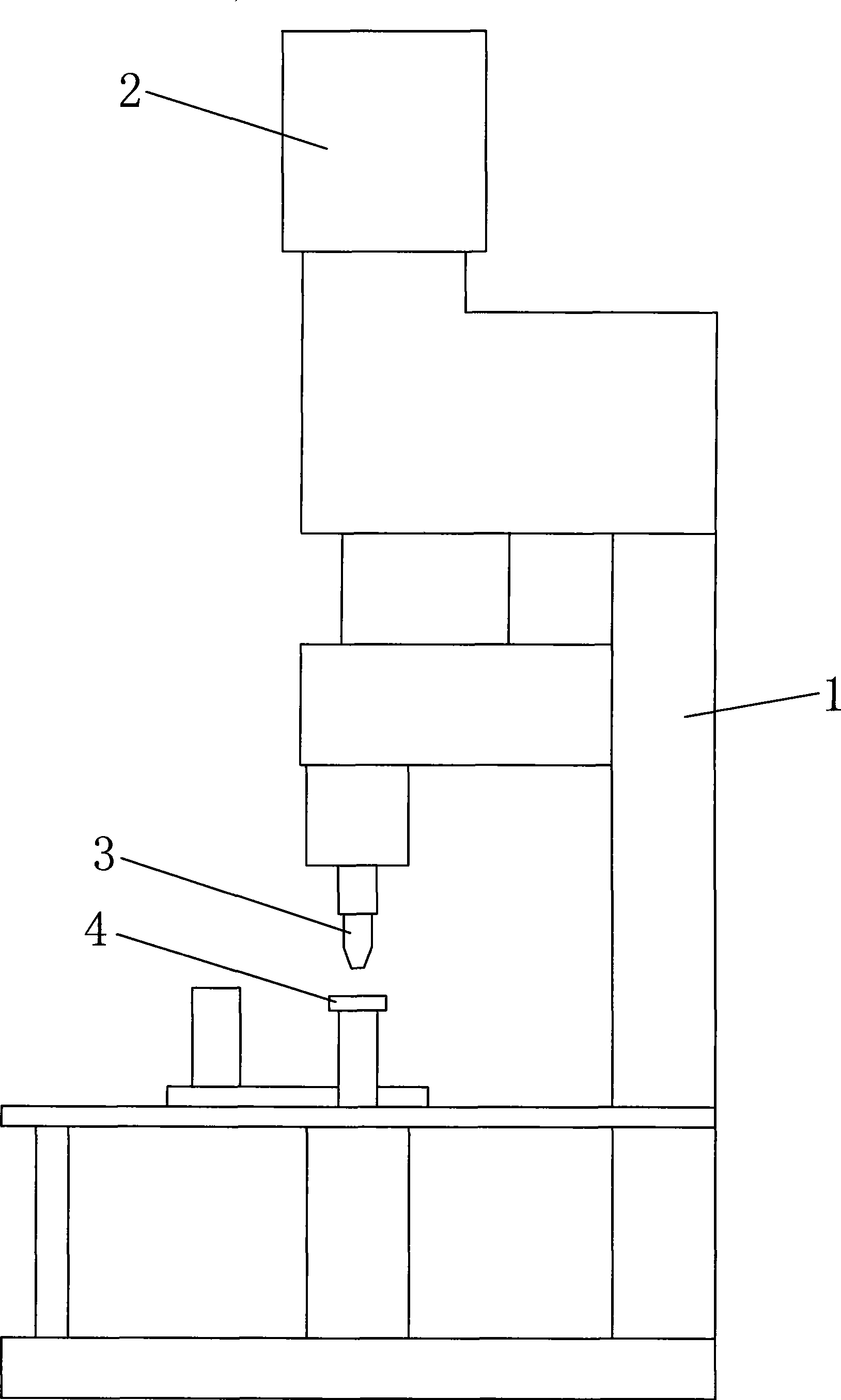

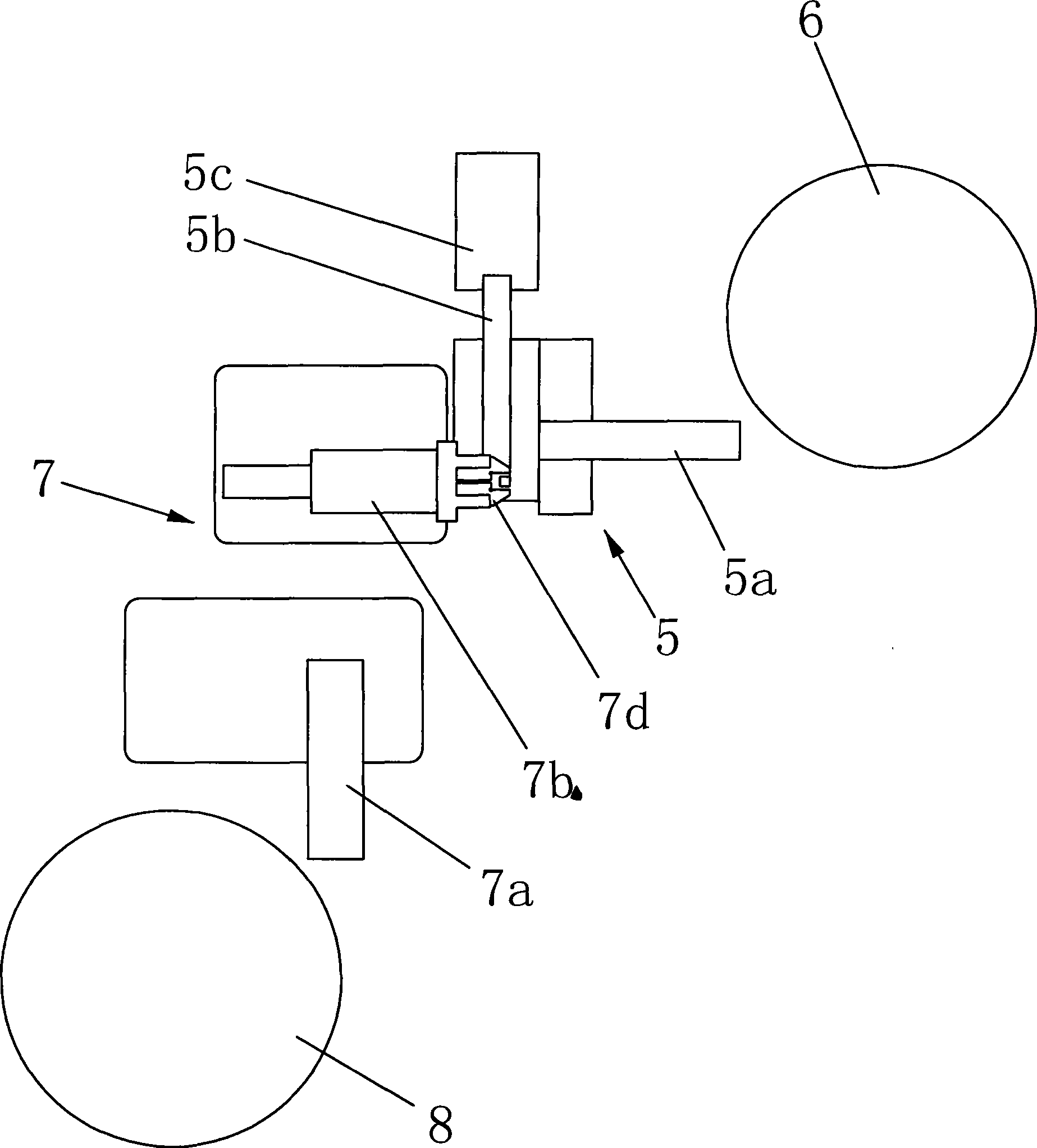

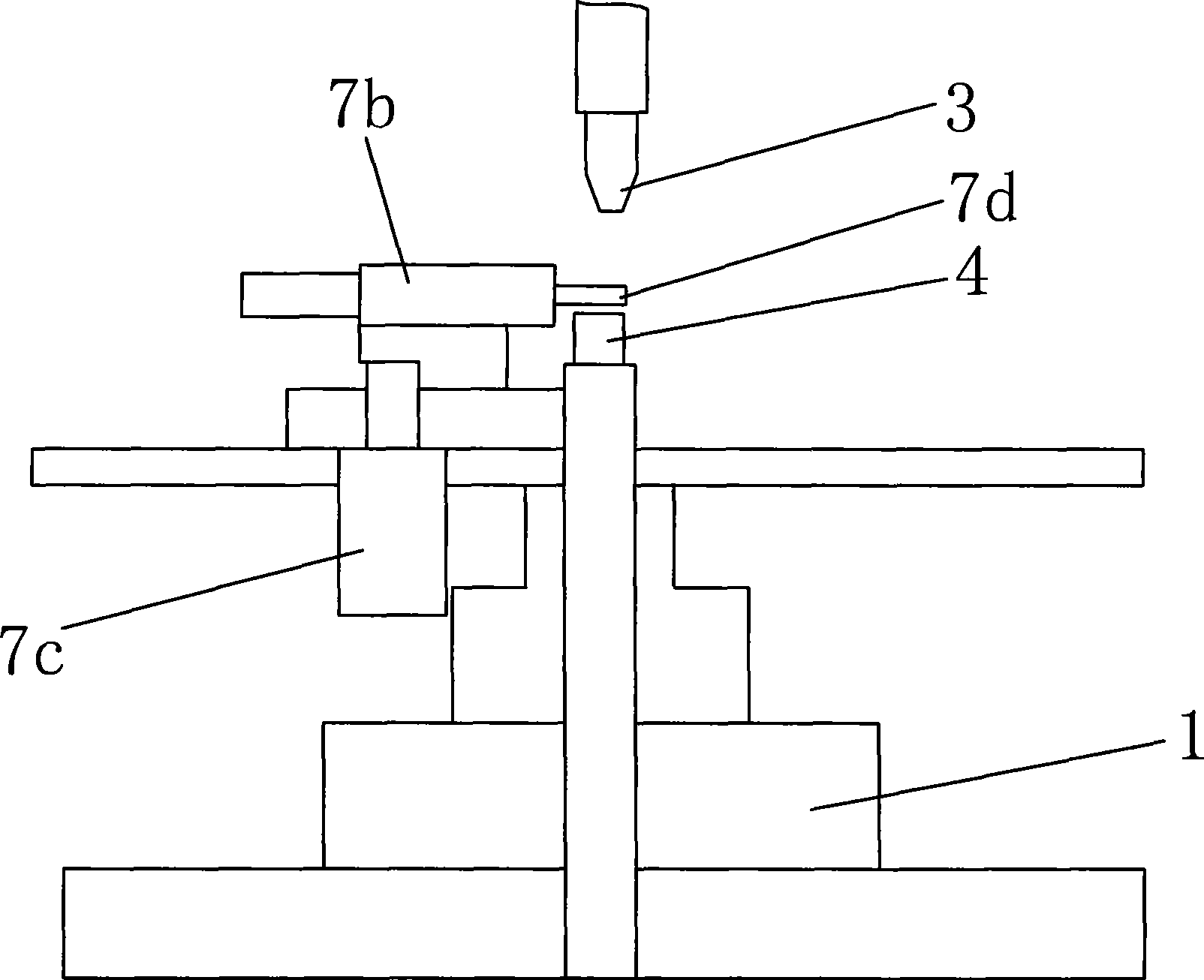

[0022] Full automatic spot welding machine see attached Figures 1 to 3 , it includes a spot welding machine body 1, the spot welding machine body 1 is a vertical machine tool, and the spot welding machine body 1 is used for installing and fixing various components.

[0023] Working cylinder 2, working cylinder 2 is fixed on the upper end of spot welding fuselage 1, and working cylinder 2 is installed vertically.

[0024] The upper electrode 3 is installed on the spot welding body 1, the upper electrode 3 is connected to the working cylinder 2, and the working cylinder 2 drives the upper electrode 3 to move up and down to realize automatic spot welding processing.

[0025] The lower electrode 4, the lower electrode 4 is fixed on the spot welding body 1, the top surface of the lower electrode 4 has a fixing hole, the lower electrode 4 is located under the upper electrode 3, the upper electrode 3 and the lower electrode 4 are aligned up and down, the upper electrode 3 and the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com