Piston pump for thick matter

A technology of mud and piston pumps, which is applied in the direction of pumps, liquid displacement machines, machines/engines, etc., to achieve the effect of improving the filling degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

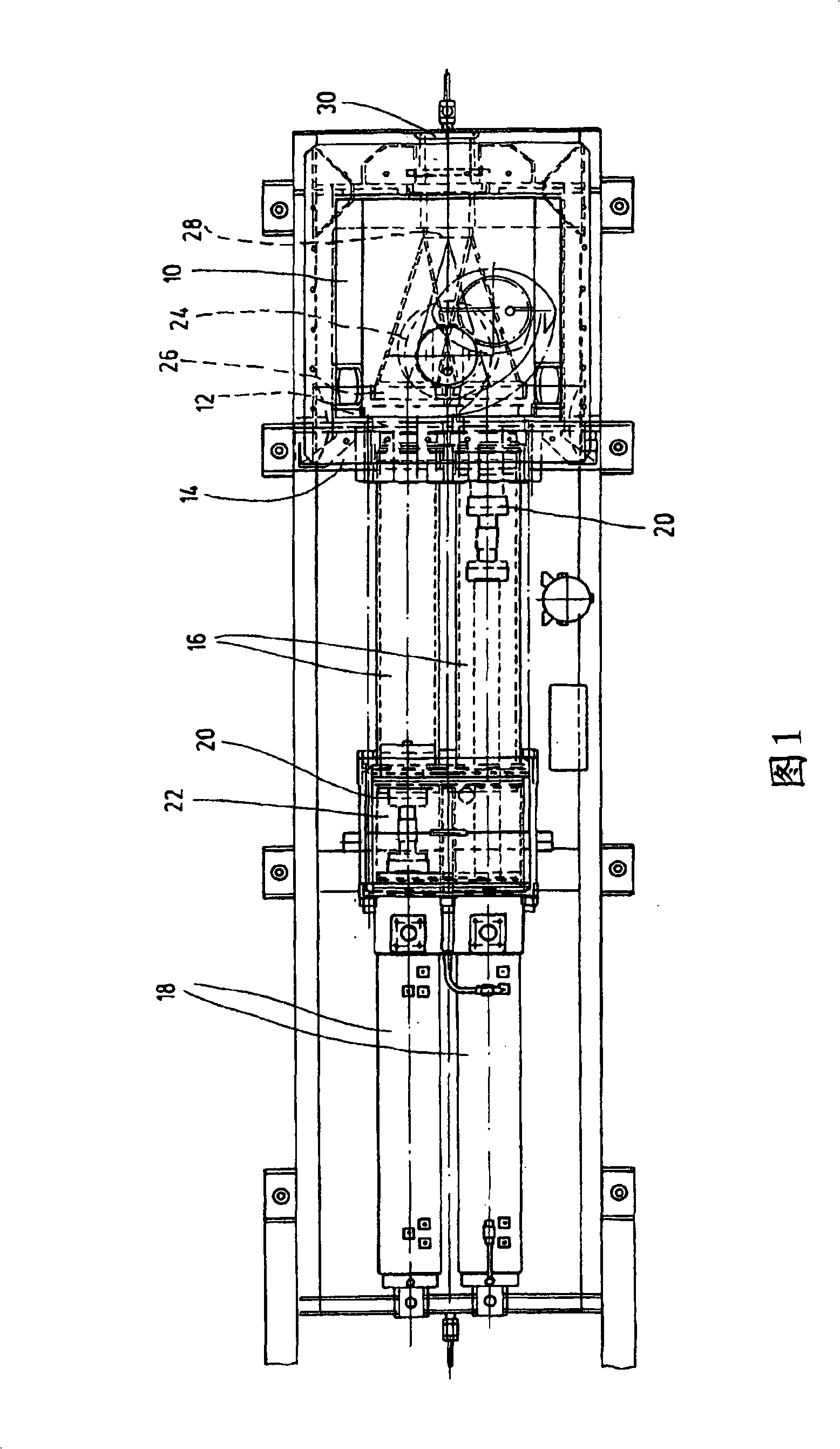

[0018] The twin-piston pump shown schematically in FIG. 1 is intended for conveying slurries with a large amount of solid matter, such as partially downed slurries, auger slurries or concrete.

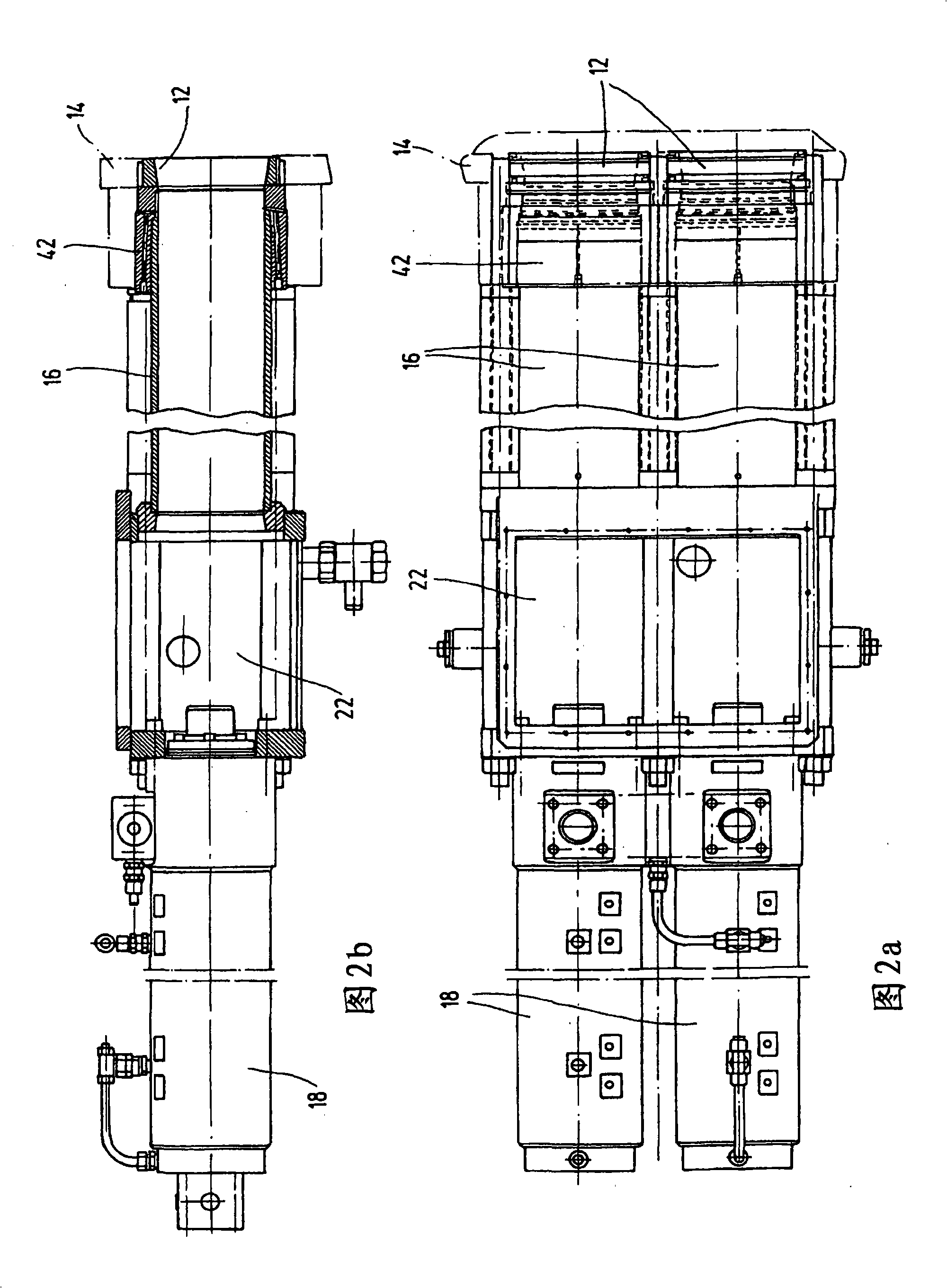

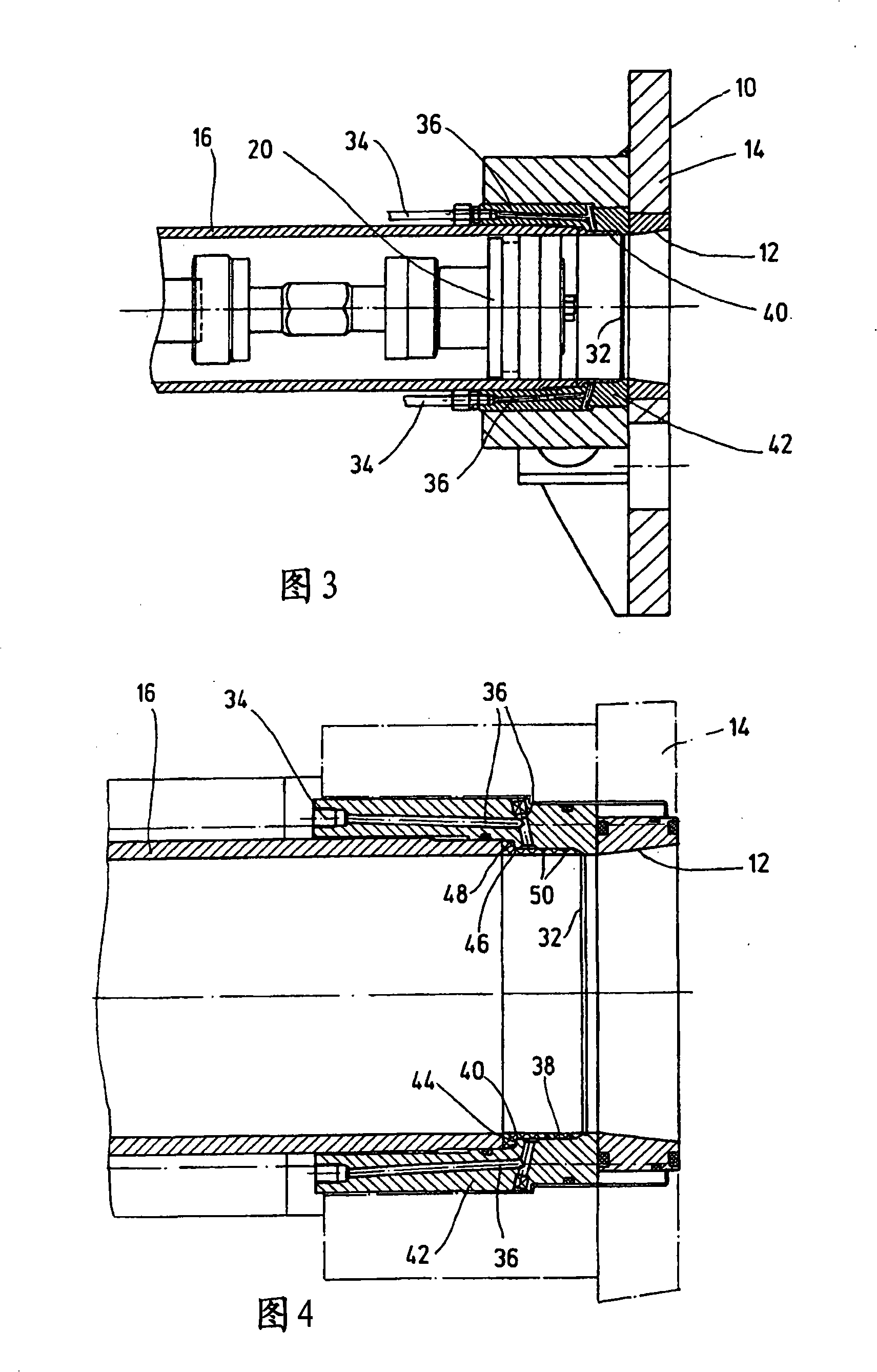

[0019] The piston pump basically comprises a feed container 10, two delivery cylinders 16 connected on the feed container 10 via wall holes 14 through two ports 12 on its end face, two push-pull hydraulically accessible pumps in the delivery cylinder 16. The delivery piston 20 driven by the drive cylinder 18 and a water tank 22 arranged between each drive cylinder 18 and each delivery cylinder 16 . A pipe slide valve 21 is arranged in the feed container 10, the pipe slide valve with its inlet 26 can be alternately connected to the port 12 of the conveying cylinder, the piston of which carries out a compression stroke and opens the other conveying cylinder The piston of the other delivery cylinder performs a suction stroke, and its outlet 28 is connected to a pressure delivery line not ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com