Closed type loading apparatus of SiC tank kiln car

A closed, kiln car technology, applied in furnaces, lighting and heating equipment, furnace components, etc., can solve the problems of difficult unloading, high labor intensity, reduced work efficiency, etc. The effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

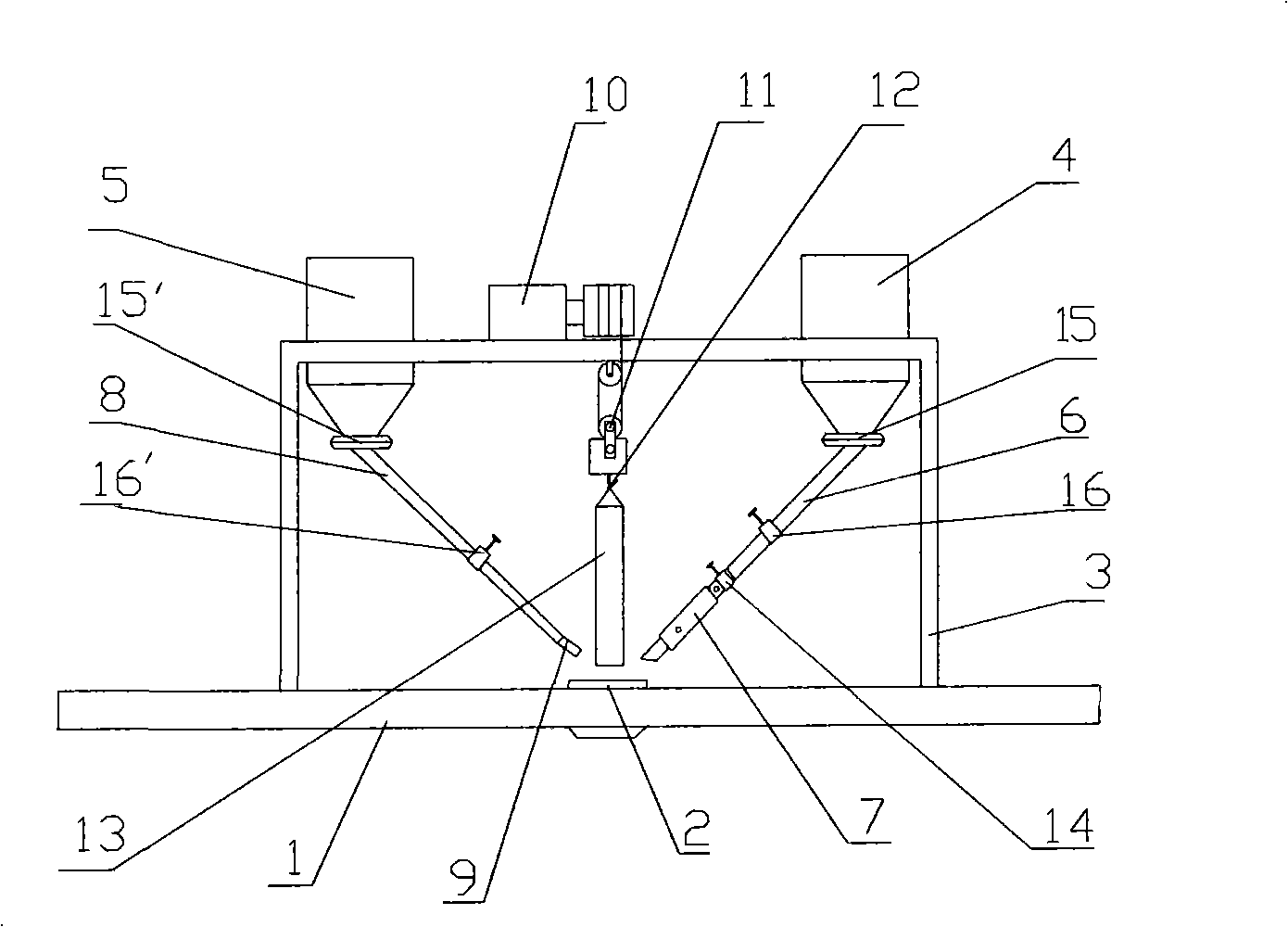

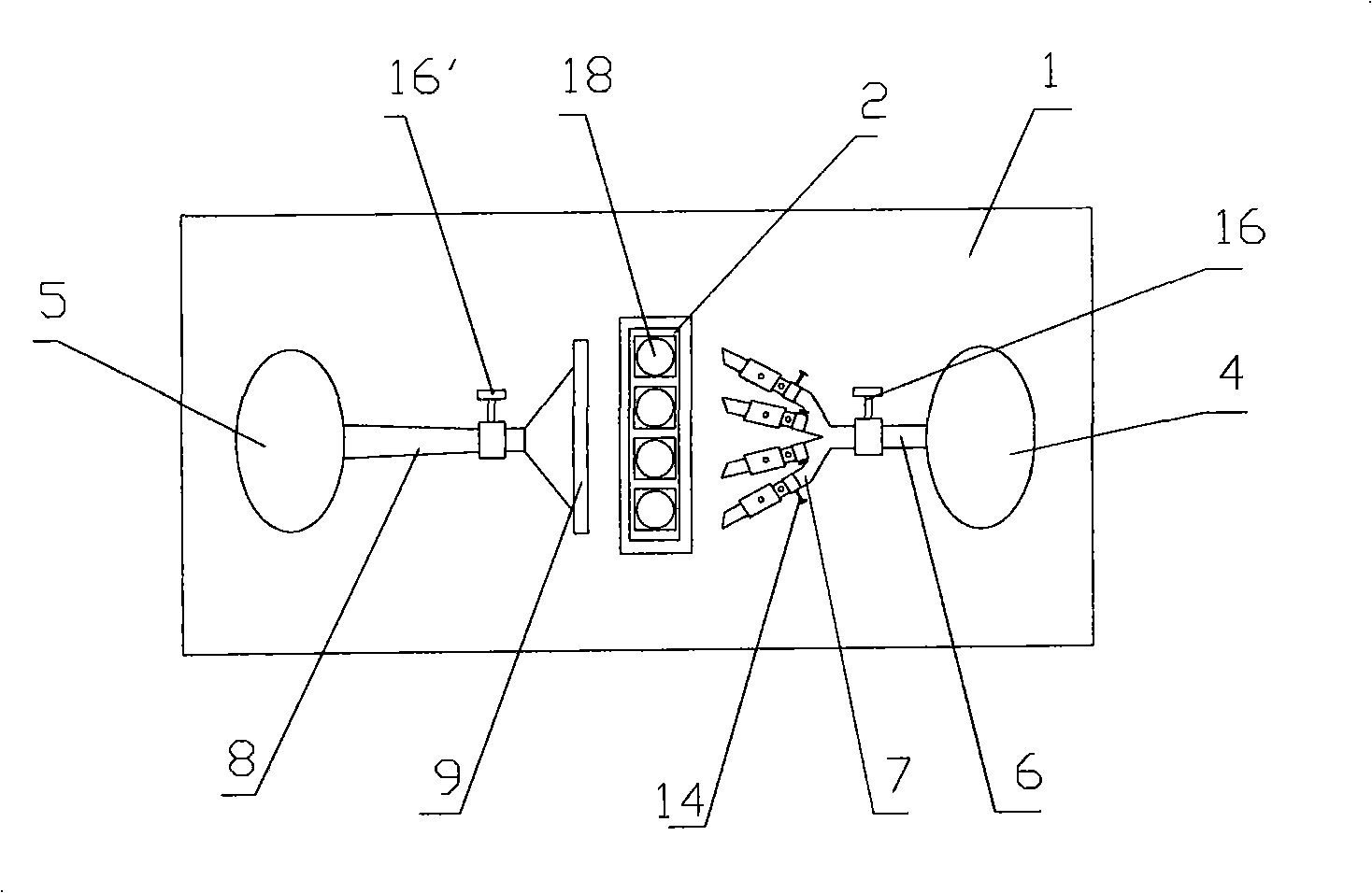

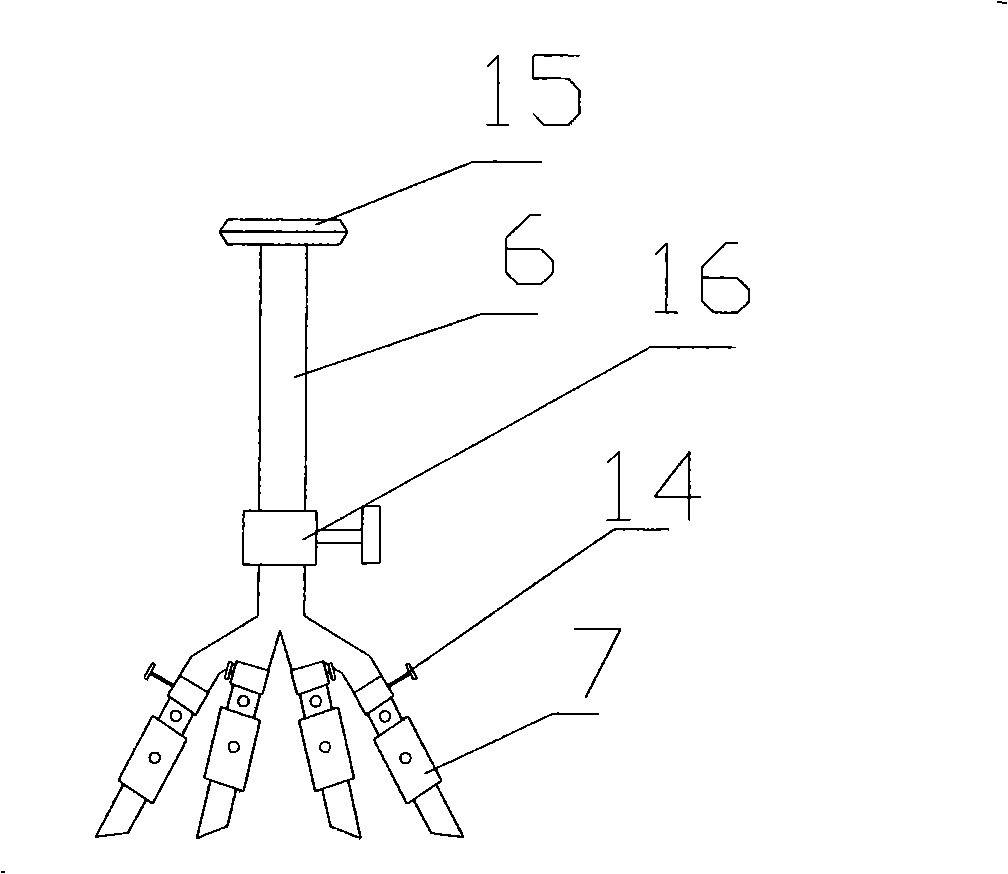

[0017] Refer to attached figure 1 , 2, 3, 4, 5, 6, 7, 8, 9 make the present invention. The SiC tank kiln car closed loading device is composed of a loading operation platform 1 and a charging tank 2. The charging tank 2 is rectangular. Corresponding to the round hole 18, the width of the charging tank 2 is consistent with the outer diameter of the SiC tank, and its length is consistent with the total length of a row of SiC tanks entering the bottom of the charging tank 2. One row is four stacks of SiC tanks, and each stack is set to five Four SiC tanks, that is, the SiC tanks arranged on the kiln car once enter the bottom of the charging tank 2 to form a stack of four stacks of SiC tanks, which are characterized in that a fixed frame 3 is set on the loading console 1, and The upper rear side of the upper part of 3 fixes the iron scale silo 4, fixes the upper coke powder silo 5 on the front side of the fixed frame 3 top, fills the iron scales in the iron scale silo 4, and in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com