Slug catching system

A technology of breaking plugs and swirl tubes, which is applied in the field of multiphase fluid transportation in oil and gas fields, can solve problems affecting the safety and normal operation of downstream equipment, equipment impact force and pressure fluctuations, etc., achieve good separation effects, reduce pressure fluctuations, reduce gas The effect of liquid entrainment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

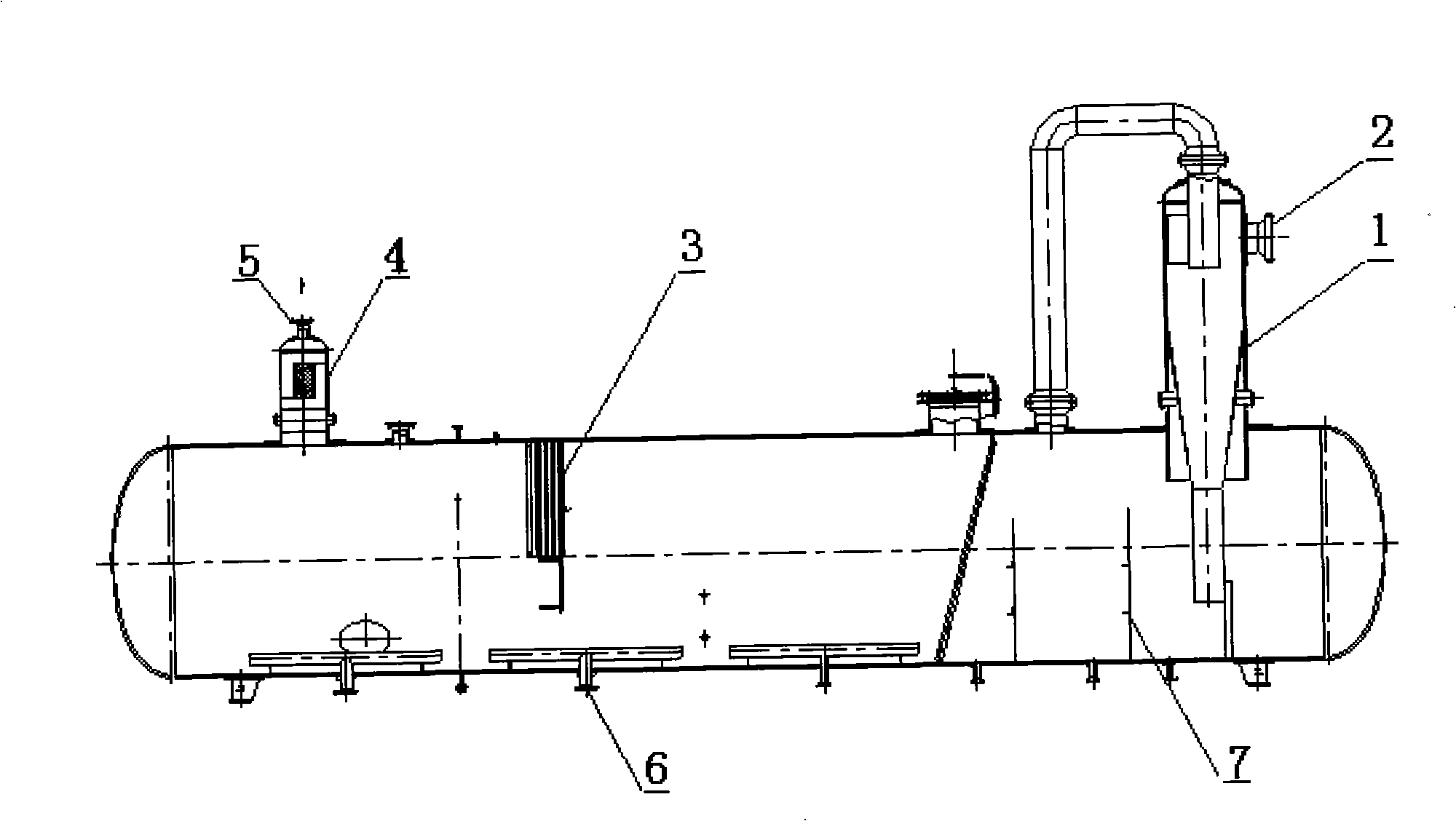

[0018] Example figure 1 As shown, the slug flow trapping device includes a cyclone device 1 , a gas rectifying device 3 , a vertical mist trapping and separating device 4 , and a buffer partition 7 . A swirl device 1 is installed vertically on the top of the right side of the tank, and the swirl device 1 is provided with a tangential inlet 2. There are two-stage buffer partitions 7 in the lower part of the swirl device 1, and the two-stage buffer partition 7 is close to the tank body to the left. An anti-vortex outlet 6 is provided at the bottom, a gas rectifying device 3 is provided near the top of the cylinder, a vertical mist trapping and separating device 4 is installed on the top of the left end of the cylinder, and the upper end of the vertical mist trapping and separating device 4 is a gas outlet 5.

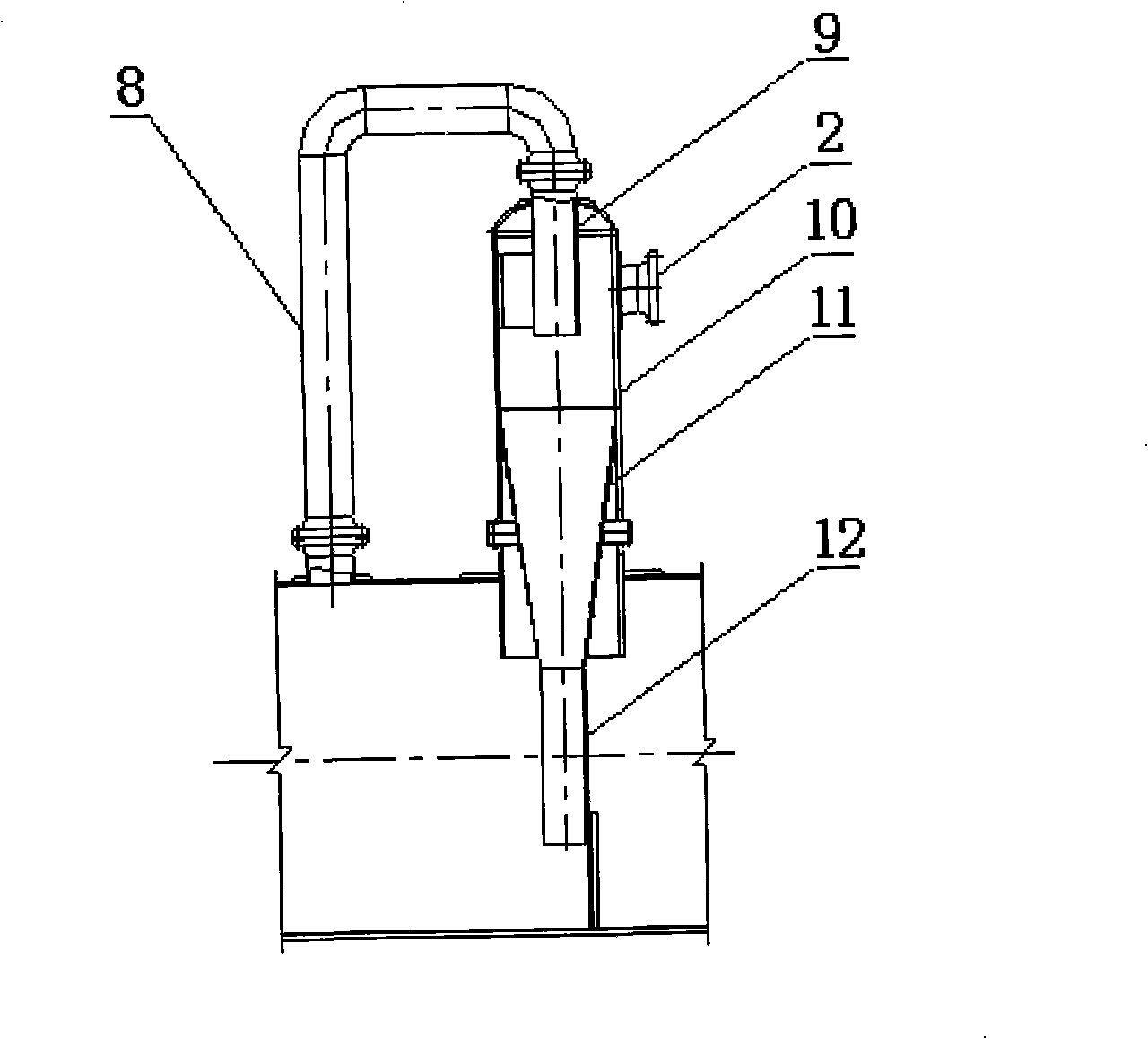

[0019] like figure 2 As shown, the cyclone device 1 includes a cyclone cylinder 10, a gas ascending section 9, a gas passing section 8, a swirl cone cylinder 11 and a li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com