Method for cooking a starchy material with a high solids content for the preparation of an adhesive composition

A technology for cooking starch and starch, applied in the direction of binder type, starch binder, fiber raw material processing, etc., can solve the problems of insufficient rheology and adhesion performance, and achieve the effect of easy drying and raw material saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0105] The device structure is shown in FIG. 3 . The start-up of the device is at point 2, providing delivery of powdered starch in the form of corn dextrin at a rate of 100 kg / h. At the same time, the flow rate of water (points 11, 12 and / or 13) is 100 l / h.

[0106] The amount of steam provided at 150°C (6) is distributed through the bottom of the cooking chamber (6-4). A temperature of 90° C. can be reached and ensured during the start-up phase.

[0107] At 150° C., the same mass of steam is supplied via point 8 to the colloidal suspension (glue) obtained by setting an average residence time in the cooking chamber of 15 minutes.

[0108] The resulting solution was passed through the coiled tube in 4 minutes, benefiting from a count-pressure set at about 5 bar and corresponding to an internal temperature of about 150°C.

[0109] Then, different recirculation conditions are determined at point 10 so that 10, 20 and 40 liters of solution are recirculated respectively, and th...

Embodiment 2

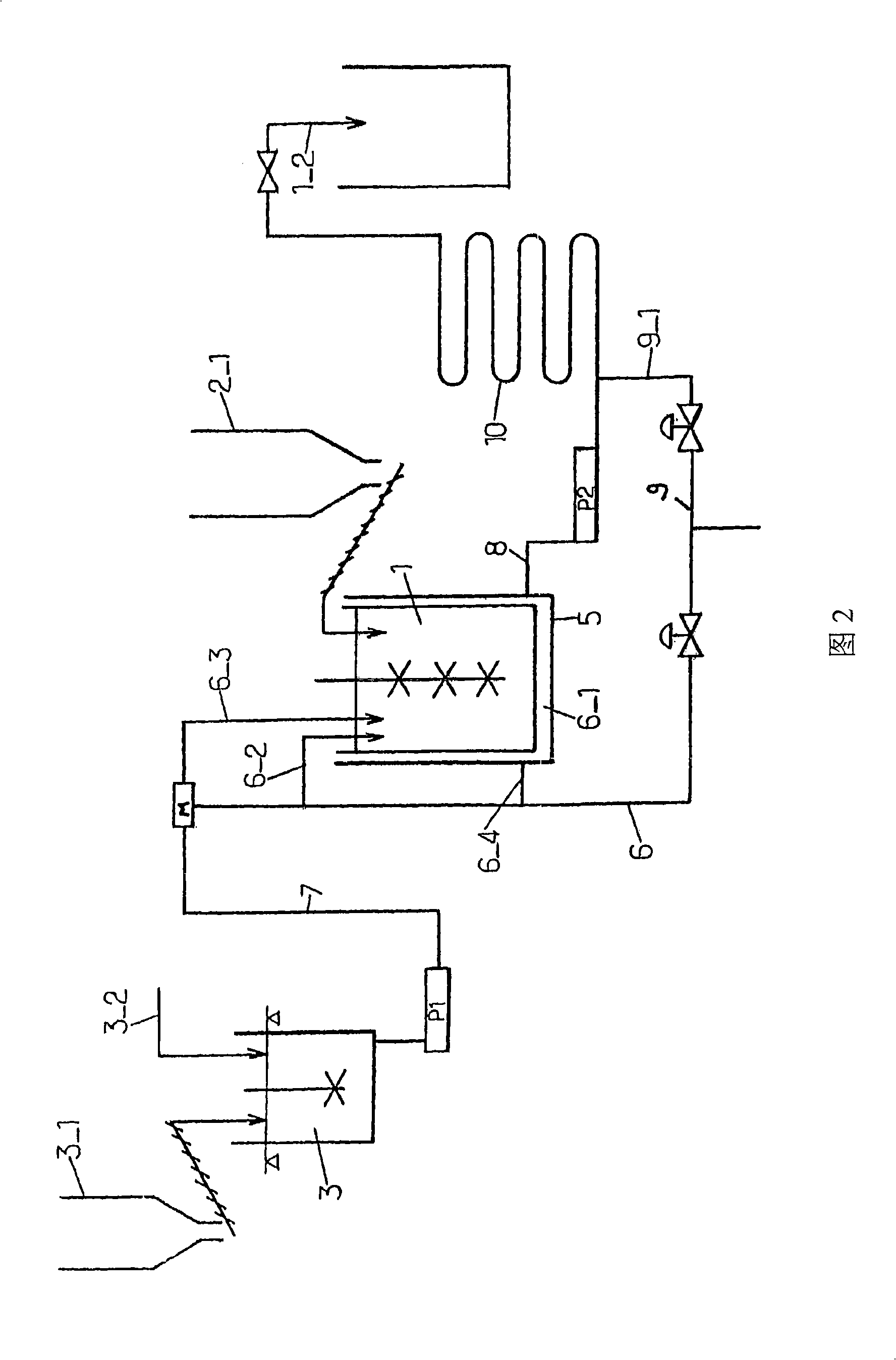

[0112] As illustrated by Figure 2, this situation corresponds to a device that does not provide glue recirculation. The corn dextrin emulsion of Example 1 obtained starting with a starch flow rate of 473.8 kg / h and a water flow rate of 710.6 kg / h was prepared continuously. The milk, having a density of 1.184 at 20°C and 40°C, received a steam flow of 110.5 kg / h at 150.4°C and a pressure of 5.4 bar (construction 6-3). The gum was produced in this way at a rate of 1294.9 kg / h at a dry matter level of 36.59% (821.1 kg / h of water + 473.8 kg / h of starch).

[0113] On the other hand, powdery starch with a water content of 10% was introduced at a flow rate of 920.1 kg / h (828 kg / h dry starch + 92 kg / h water).

[0114] Starting from these conditions, the ratio of powder / glue is defined as 71.0%, and the ratio of powder / (glue+powder) is 41.54%.

[0115] Thus, the cooking chamber receives 913.1 kg / h of water and 1301.8 kg / h of starch in the form of glue or powder at a temperature of ab...

Embodiment 3

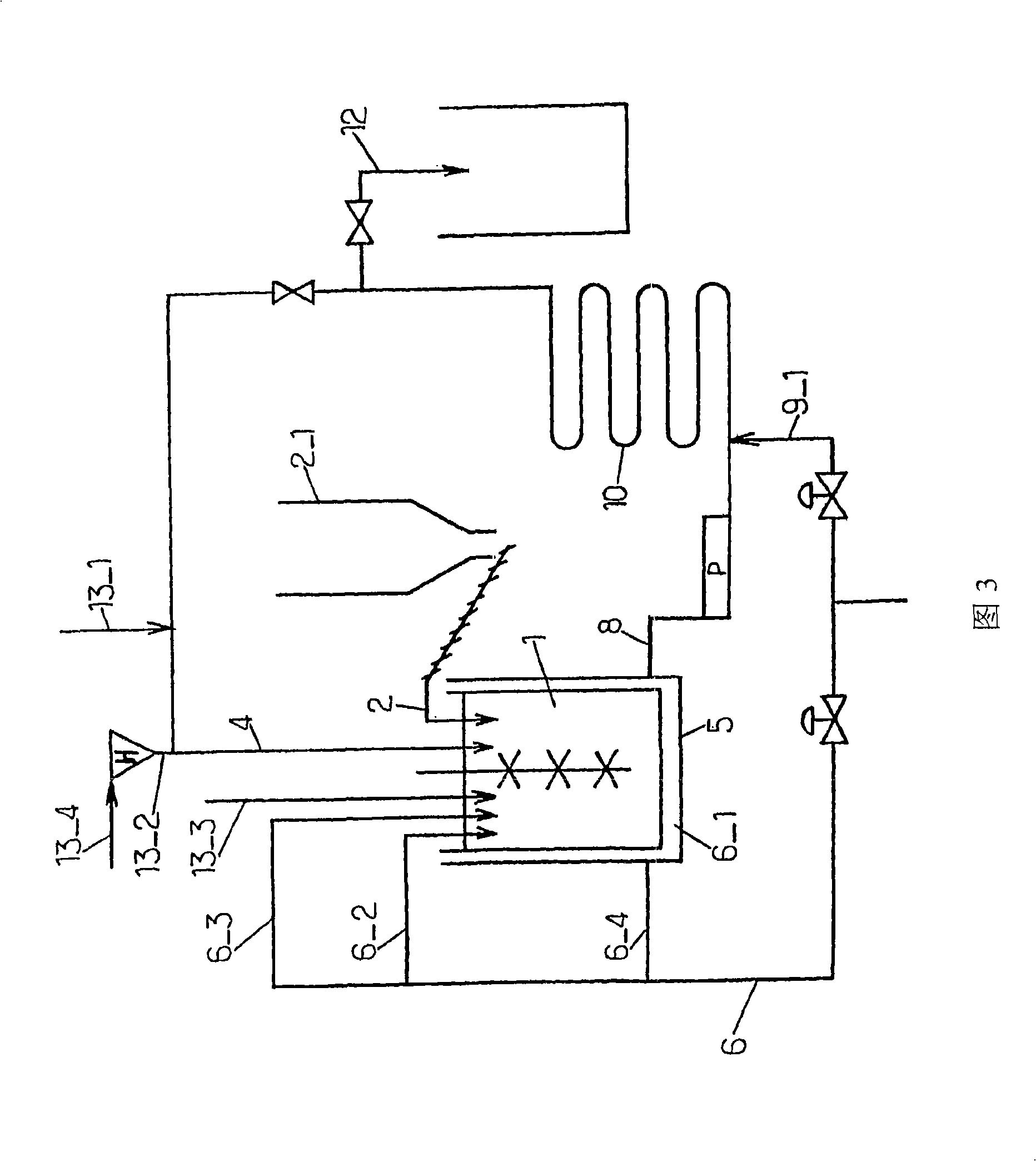

[0120] FIG. 1 illustrates the situation disclosed in this embodiment. This time, this example corresponds to a device that provides for the recycling of glue that has been added to the carrier fluid in the form of glue derived from the preparation of starch emulsions.

[0121] The flow rates of the gum and starch emulsions derived from this (structure 6-3) were those of Example 2.

[0122] On the other hand, the glue produced at the outlet of the coiled tube no longer leads fully to the machine. The majority (1500 kg / h) is diverted and recycled in order to constitute the carrier fluid for the envisaged cooking. This operation results in a significant increase in the flow rate of the powdered starch. In fact, it increased to 1559.2 kg / h (1403.3 kg / h dry starch + 155.9 kg / h water).

[0123] The established system was profoundly changed. In fact, the cooking chamber received a mixture with 63.09% dry matter at a total flow rate of 4354.15 kg / h (1607.1 kg / h of water + 2747.05 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com