Assembly type puncture connection electrode

An electrode-connected and assembled technology, applied in ohmic resistance electrodes, ohmic resistance heating parts, floors, etc., can solve the problems of cumbersome connection methods, and it is not easy to ensure the insulation performance of electric heating floors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

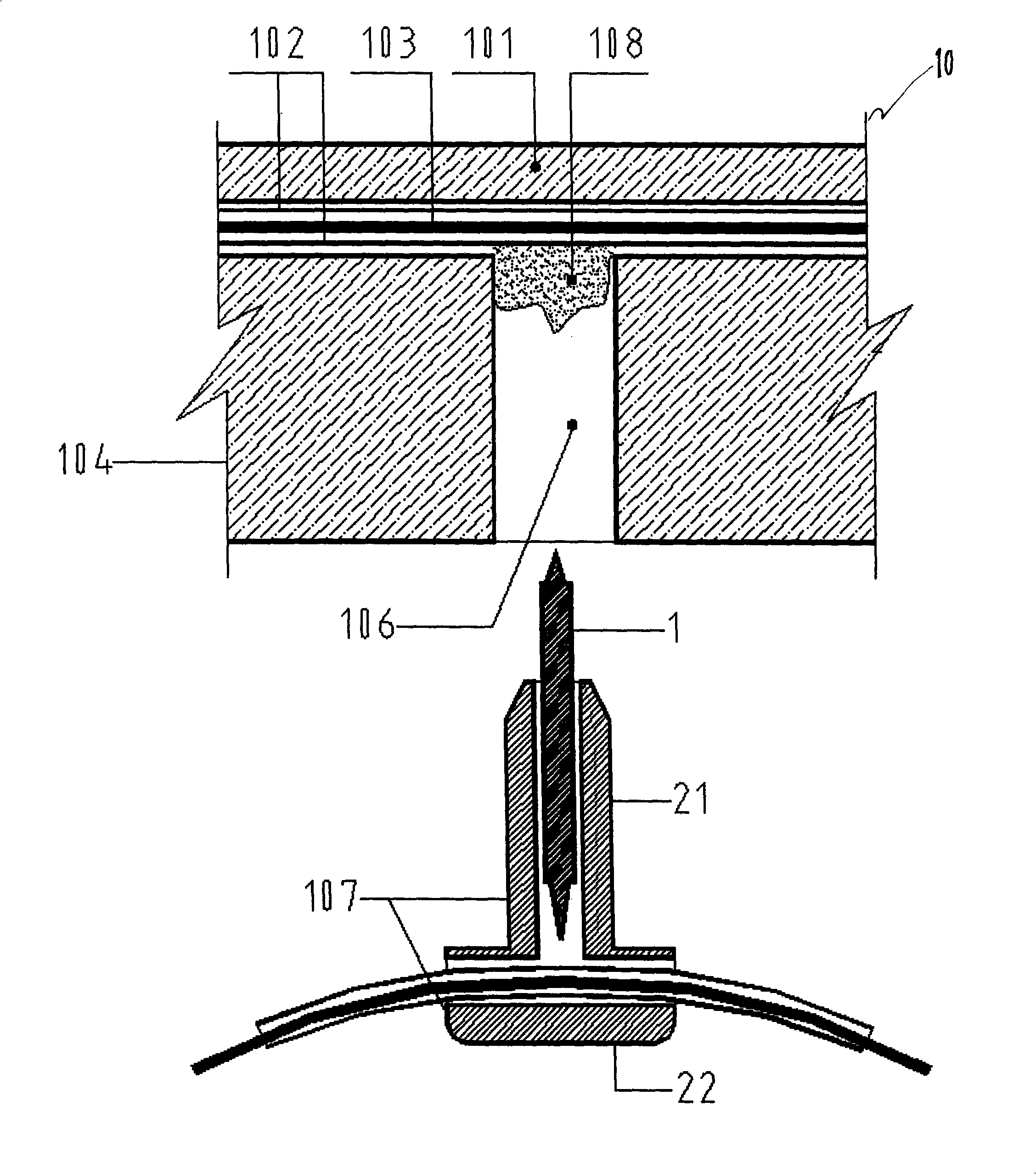

[0024] The present invention will be further described below in conjunction with the accompanying drawings. It should be clear that the specific embodiments of the present invention described in the drawings are only for illustrating the present invention, and do not constitute a limitation to the present invention. The protection scope of the present invention is defined by the appended claims.

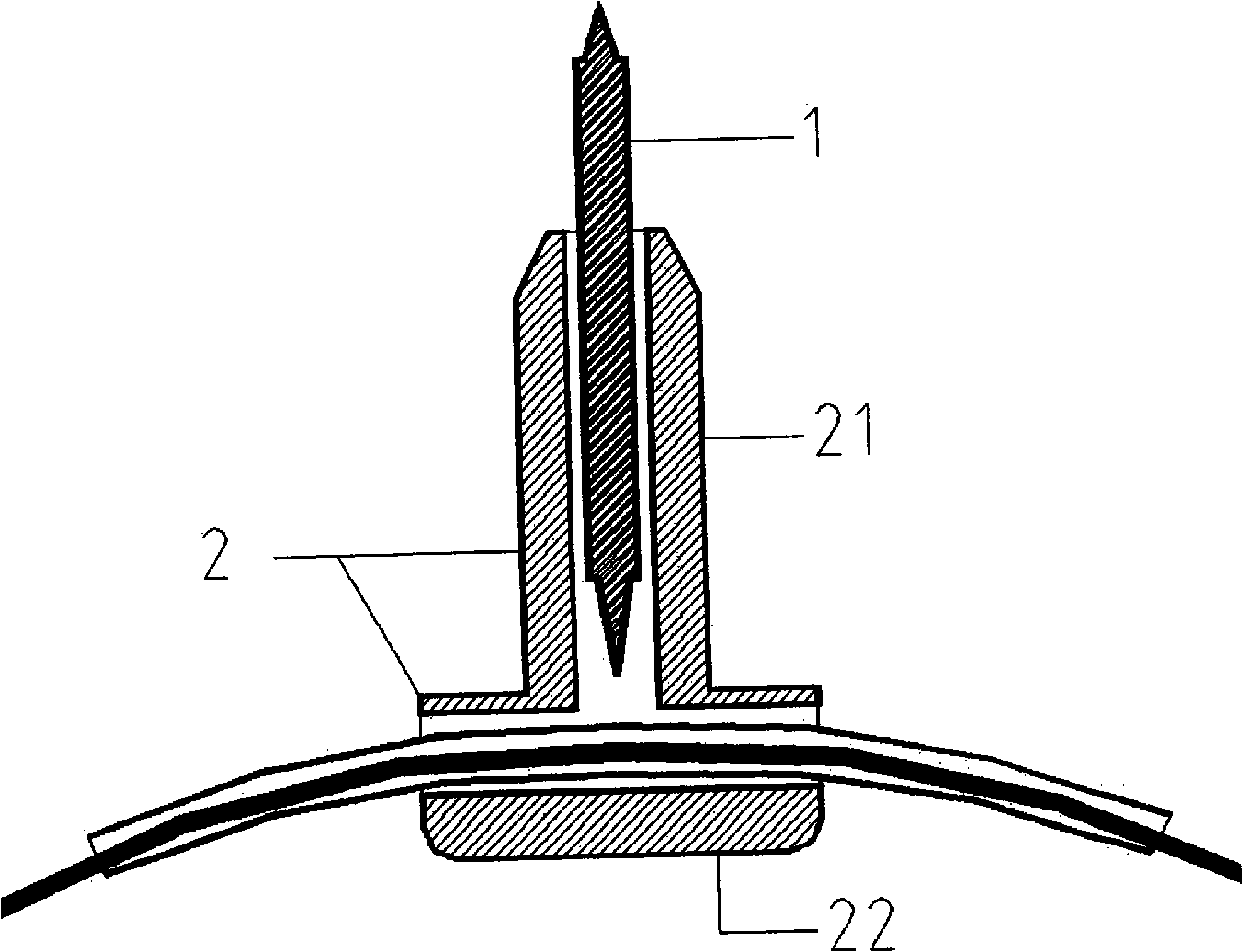

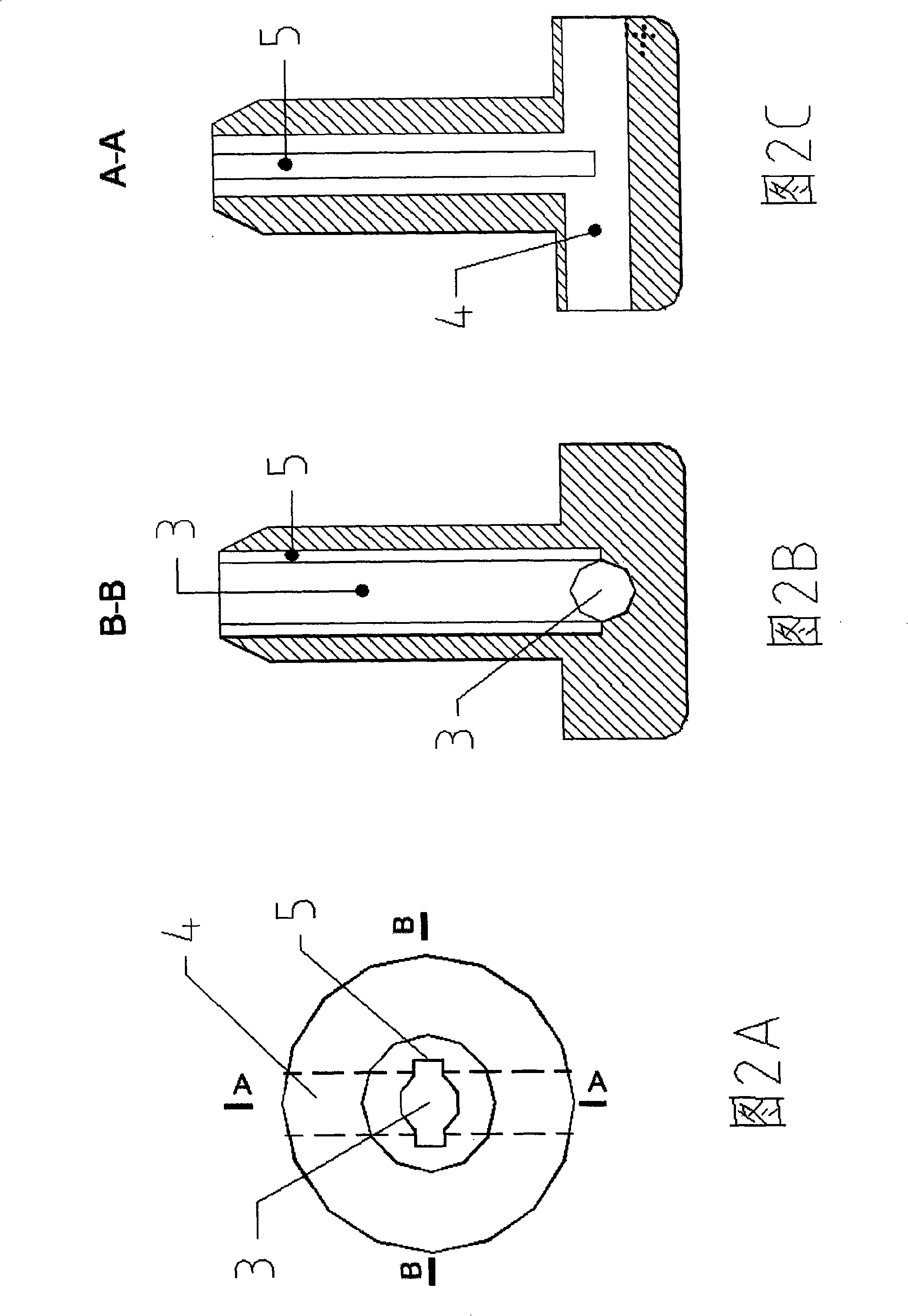

[0025] figure 1 It is a schematic cross-sectional structure diagram of the assembled puncture connection electrode in the present invention. Such as figure 1 As shown, the assembled piercing connection electrode in the present invention includes a conductive metal needle 1 and an electrode plastic part 2 . The electrode plastic part comprises a cylindrical upper part 21 and a lower part 22 . The conductive metal needle 1 is elongated and needle-shaped made of copper material, and its cross section is circular. The electrode plastic part 2 has a conductive metal pin insertion hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com