Printing ink and method for mending dry plate pinhole defect by using the same

An ink and defect technology is applied in the field of ink and the use of the ink to repair pinhole defects in dry plates, which can solve problems such as insufficient adhesion, achieve good adhesion and light blocking, and improve quality.

Inactive Publication Date: 2009-04-08

深圳清溢光电股份有限公司

View PDF0 Cites 3 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] The purpose of the present invention is to provide an ink and a method for using the ink to repair pinhole defects in dry plates, aiming to solve the problem of insufficient adhesion after repairing with other repair materials and repair methods in the dry plate industry

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0022]

Embodiment 2

[0024]

Embodiment 3

[0026]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

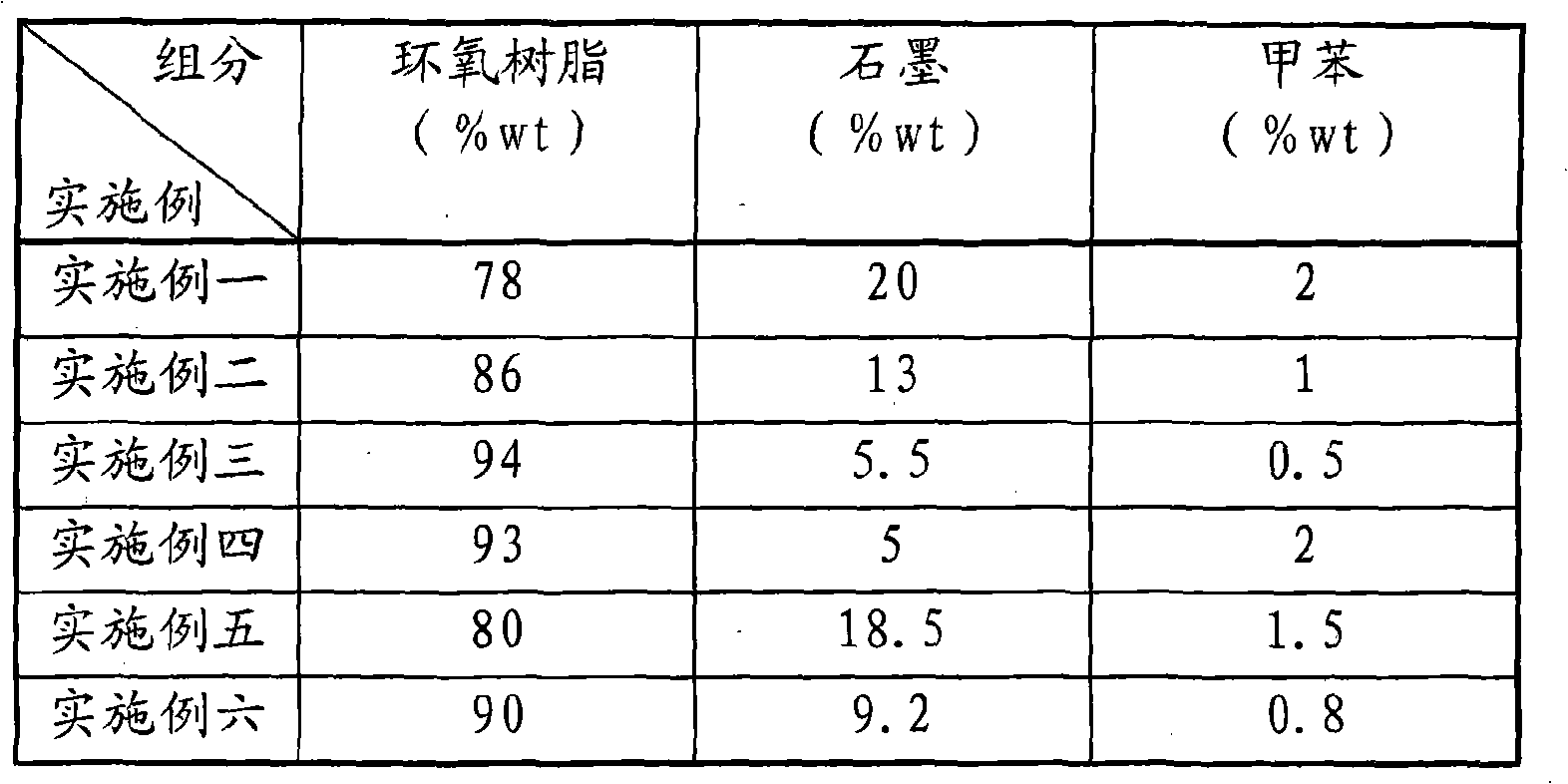

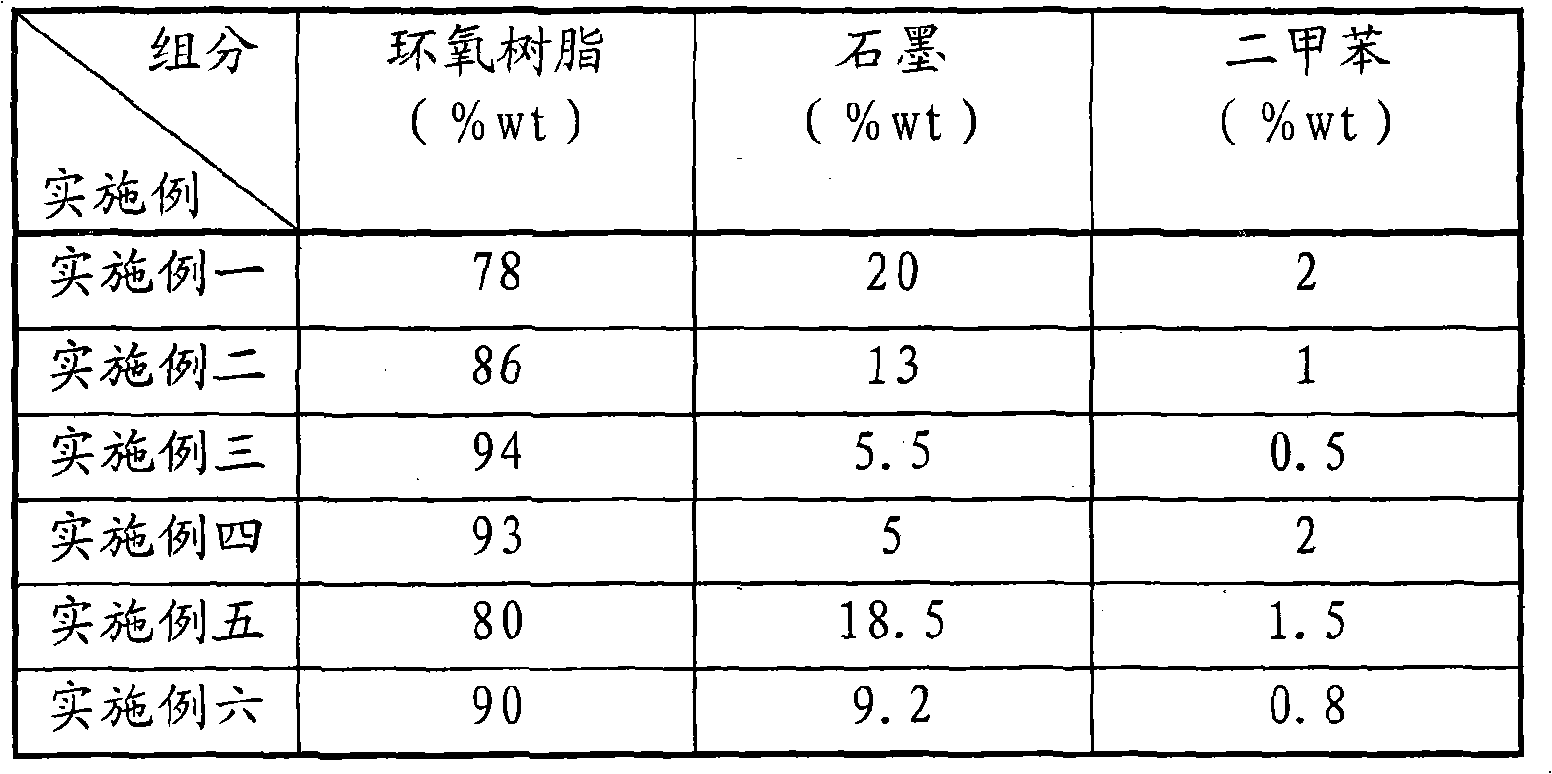

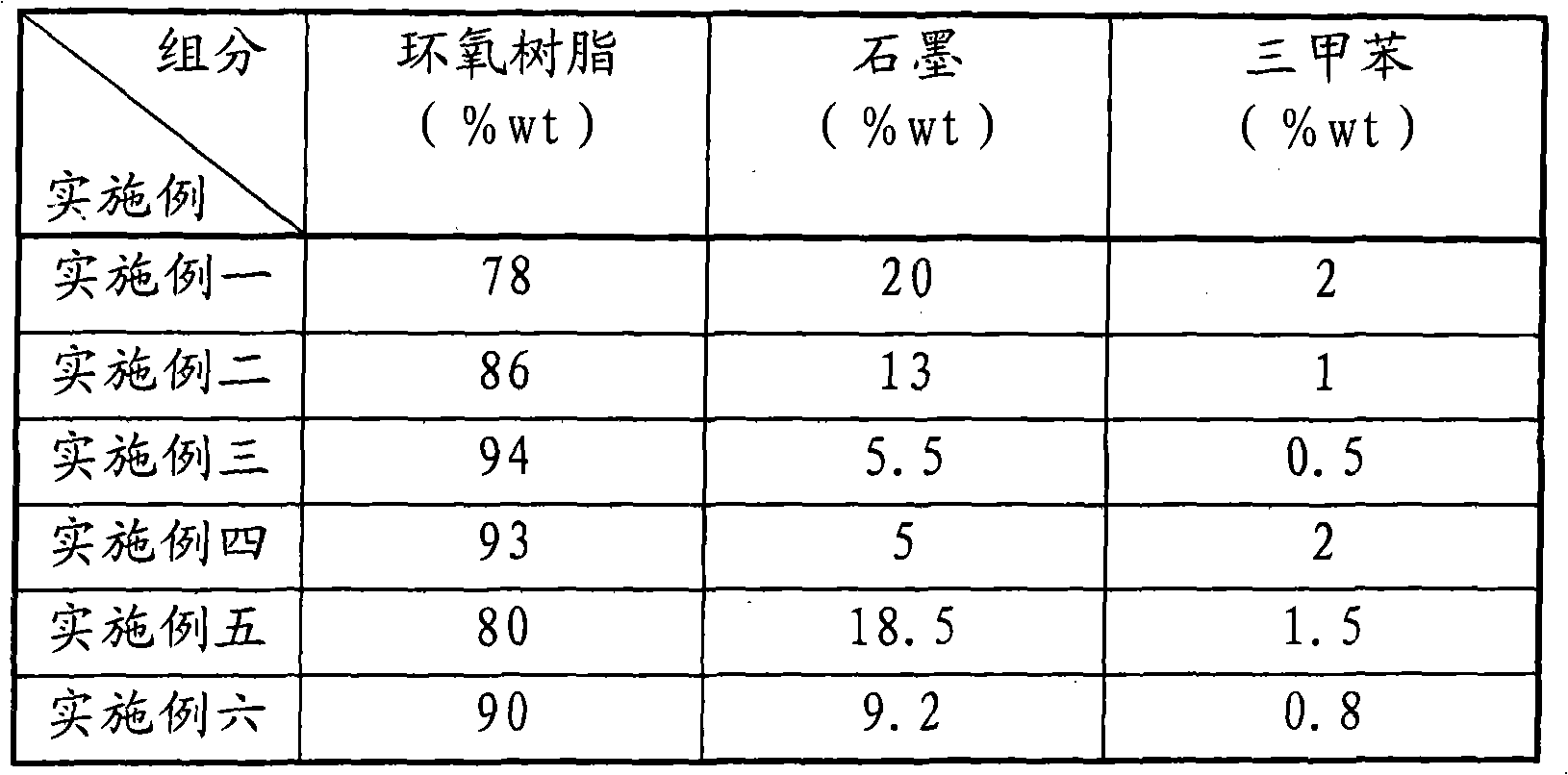

The invention is applicable to the technical field of mask defect repair methods, and provides a printing ink for repair. The printing ink comprises the following raw materials according to the parts by weight: 78-94wt% of a bonding agent, 5-20wt% of a pigment, and 0.5-2wt% of a diluent, wherein, the bonding agent is an epoxy resin or phenolic resin; the pigment is carbon powder, such as graphite; and the diluent is any one of toluene, xylene, trimethylbenzene, turpentine or camphorated oil. The invention further provides a method for repairing dry plate pinhole defects by the printing ink. The printing ink and the method for repairing the dry plate pinhole defects can effectively repair the dry plate pinhole defects, and cause the repaired dry plate to withstand a plurality of times of wiping and cleaning with organic cleaning agents, inorganic cleaning agents or deionized water, and cause the dry plate to have excellent adhesive force and light resistance, thus effectively improving the quality of the dry plate.

Description

technical field [0001] The invention belongs to the technical field of mask plate defect repair methods, in particular to an ink and a method for repairing pinhole defects of a dry plate using the ink. Background technique [0002] At present, the dry plate in the mask plate industry often produces pinhole defects. The pinhole defect is also called white defect in the mask plate industry. It refers to the influence of certain factors during the production and use of the dry plate. The defects formed by light-transmitting holes appear in the originally black shading area of the graphic effective area, and are also called sags or broken lines with changes in their size, position, and shape. Repairing such pinhole defects mainly involves the use of red clay, professional film repair pens or other light-blocking substances. Although red clay can be used for repairing, it can resist the wiping of organic solvents, but it will be damaged when it encounters water or high humidity...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G03F1/00G03F1/72

Inventor 王金木

Owner 深圳清溢光电股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com