Sample heating apparatus used for rock impact experiment

A technology of impact experiment and heating device, which is applied in the direction of using one-time impact force to test the strength of materials and the preparation of test samples. It can solve the problems of large difference in intermediate temperature and rapid drop, and prevent damage and breakdown. The effect of high-speed impact and heat loss prevention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

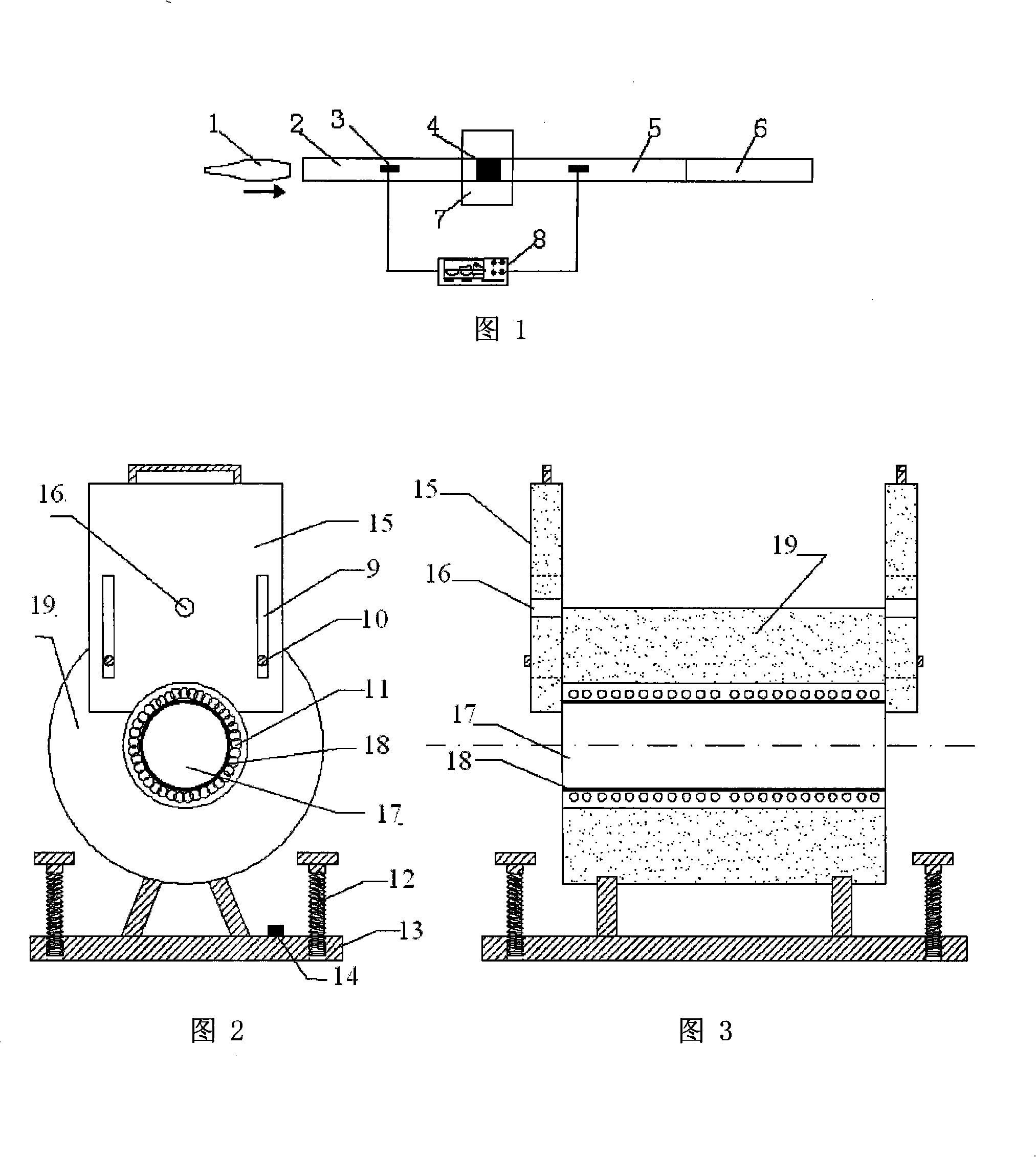

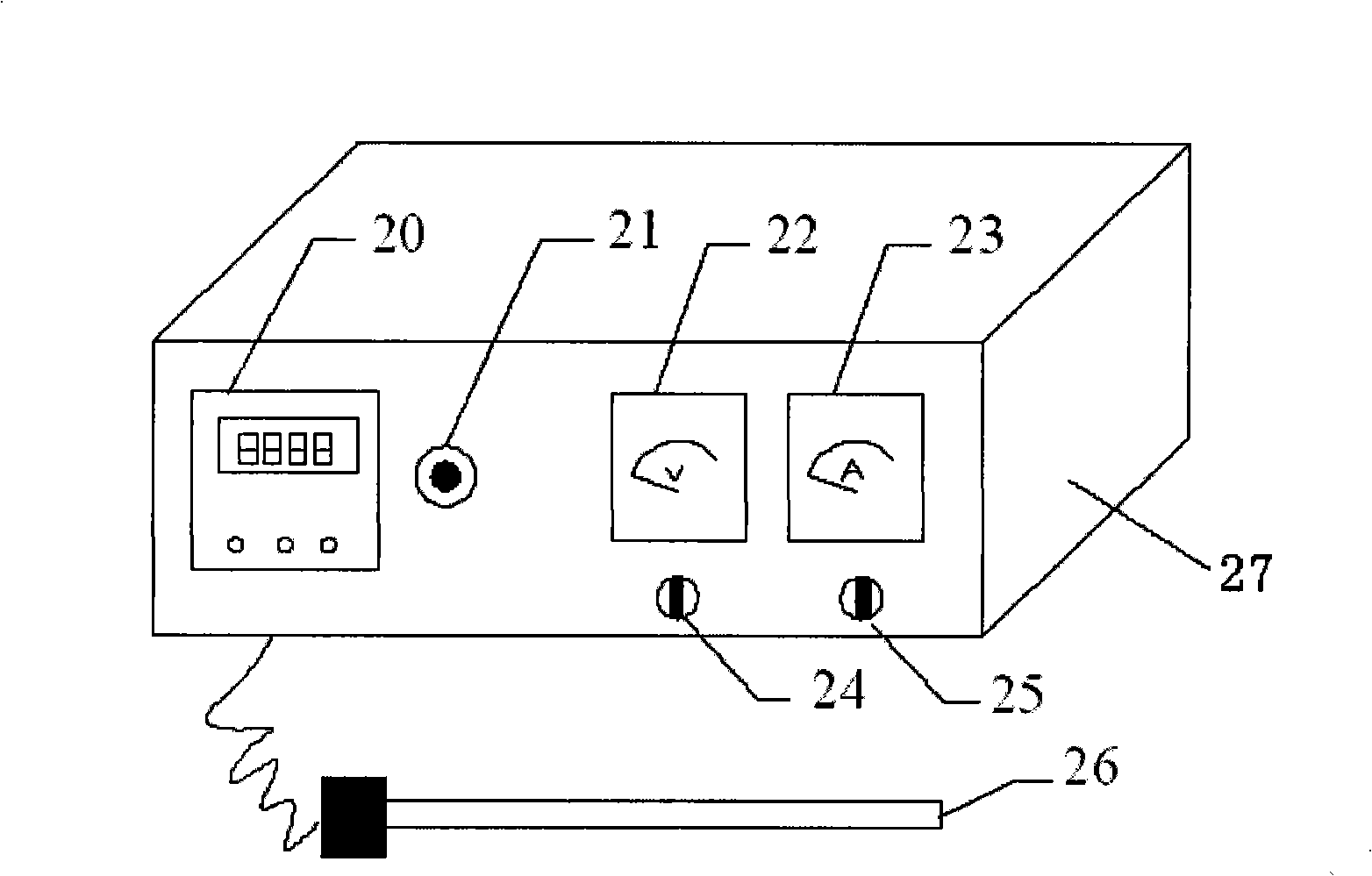

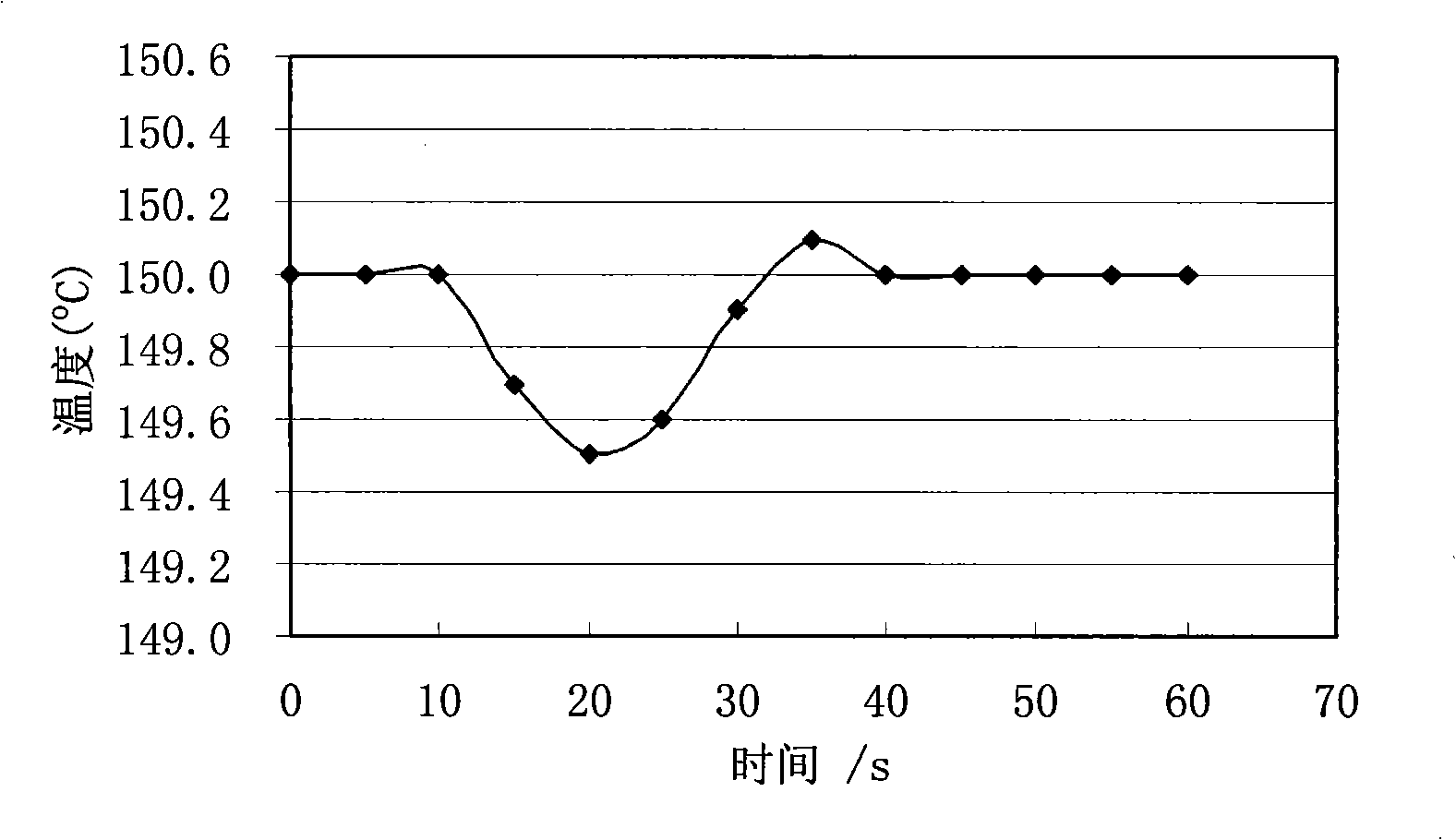

[0030] See Figure 2, Figure 3 and Figure 4 , the structure of the heating device 7 is: the support 13 is provided with a thermal insulation bin 19, and the axial level in the thermal insulation bin 19 is provided with a carbon fiber reinforced alloy cylinder 18, and a heating chamber 17 is formed in the carbon fiber reinforced alloy cylinder 18, and the carbon fiber reinforced alloy cylinder 18 There is a resistance wire 11 on it, and the resistance wire 11 is electrically connected with the heating chamber temperature monitoring and control instrument 27 through the power switch 14. The heating chamber temperature monitoring and control instrument 27 is electrically connected with a thermocouple 26, and a heating The two ports of the chamber 17 correspond to the adjustable heat preservation door 15 respectively. The adjustable heat preservatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com