Oil cooling system used for evaporation refrigeration type condenser and screw units

A technology of oil cooling system and screw unit, which is applied to components of pumping devices for elastic fluids, refrigerators, refrigeration components, etc., and can solve the problem of high location limitations of equipment components, large refrigerant charge, and unit In order to avoid problems such as low degree of automation, the installation space is reduced, the oil temperature is stable, and the height difference is low.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

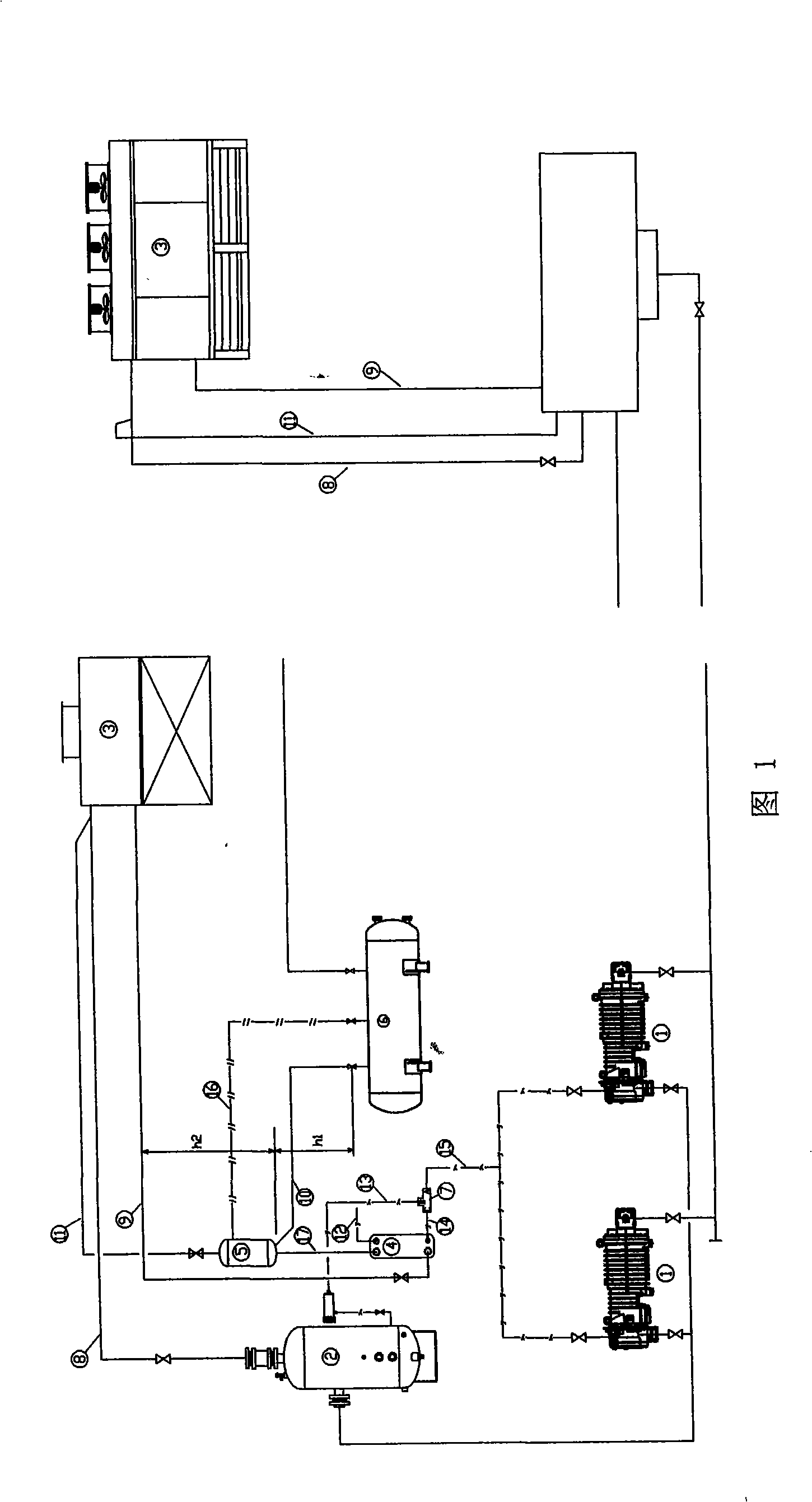

[0007] Referring to Figure 1, an oil cooling system for an evaporative cooling condenser and a screw unit, wherein the refrigerant pipeline: the screw compressor 1 is connected to the oil separator 2, and the oil separator 2 passes through the compressor exhaust pipe 8 Connect to the condenser 3, which is characterized in that the condenser 3 is connected to the oil cooler 4 through the condenser liquid outlet pipe 9, the oil cooler 4 is connected to the vapor-liquid separator 5 through the vapor-liquid mixing pipe 17, and the vapor-liquid separator 5 is connected to the liquid pipe 10 Connect the high-pressure liquid reservoir 6, the upper end of the vapor-liquid separator 5 is connected to the exhaust pipe 8 of the compressor through the siphon pipe 11, and the high-pressure liquid reservoir 6 is connected to the vapor-liquid separator 5 through the balance pipe 16; the oil pipeline: the oil separator 2 passes through the oil pipe 12 is connected to the oil inlet of the oil c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com