A multi-connected horizontal vacuum fryer

A technology of vacuum frying machine and horizontal oil, which is applied in the direction of oil/fat baking, etc., which can solve the problems of complex supporting facilities, increased pipeline resistance, and low processing efficiency, so as to achieve high facility utilization, prolong the service life, and improve The effect of work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with accompanying drawing.

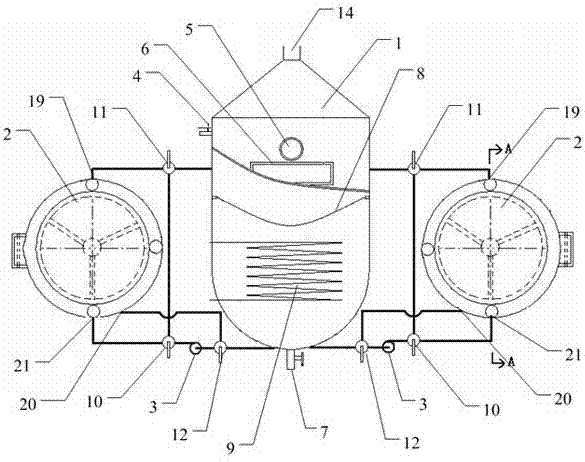

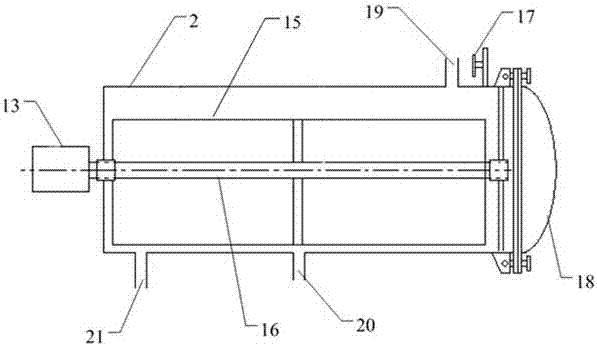

[0014] like Figure 1 to Figure 2 As shown, a multi-connected horizontal vacuum fryer includes a motor 13, a horizontal fryer 2, an oil pump 3, and an oil tank 1. One end of the horizontal fryer 2 is provided with a motor 13, and the other end is provided with a A pot cover 18, the top of the horizontal fryer 2 is provided with a pot body exhaust valve 17, and a material basket 15 is arranged inside it, and a shaft 16 is connected in the middle of the material basket 15, and the shaft 16 is connected to the shaft of the motor 13. connection, the top of the oil tank 1 is connected to the vacuum device through the vacuum system interface 14, the upper part of the tank body of the oil tank 1 is provided with an exhaust valve 4 and a slag outlet 6, and the bottom end is provided with a discharge valve 7 The tank body of the oil tank 1 is provided with a filtering device 8 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com