A constant temperature and pressure lubrication equipment

A lubricating equipment, constant temperature and constant pressure technology, applied in the direction of engine lubrication, mechanical equipment, lubricating parts, etc., can solve the problems of unstable oil temperature and oil pressure in the lubricating system, easy to fluctuate, etc., achieve rapid stability and improve stability , the effect of stabilizing the oil temperature of lubricating oil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

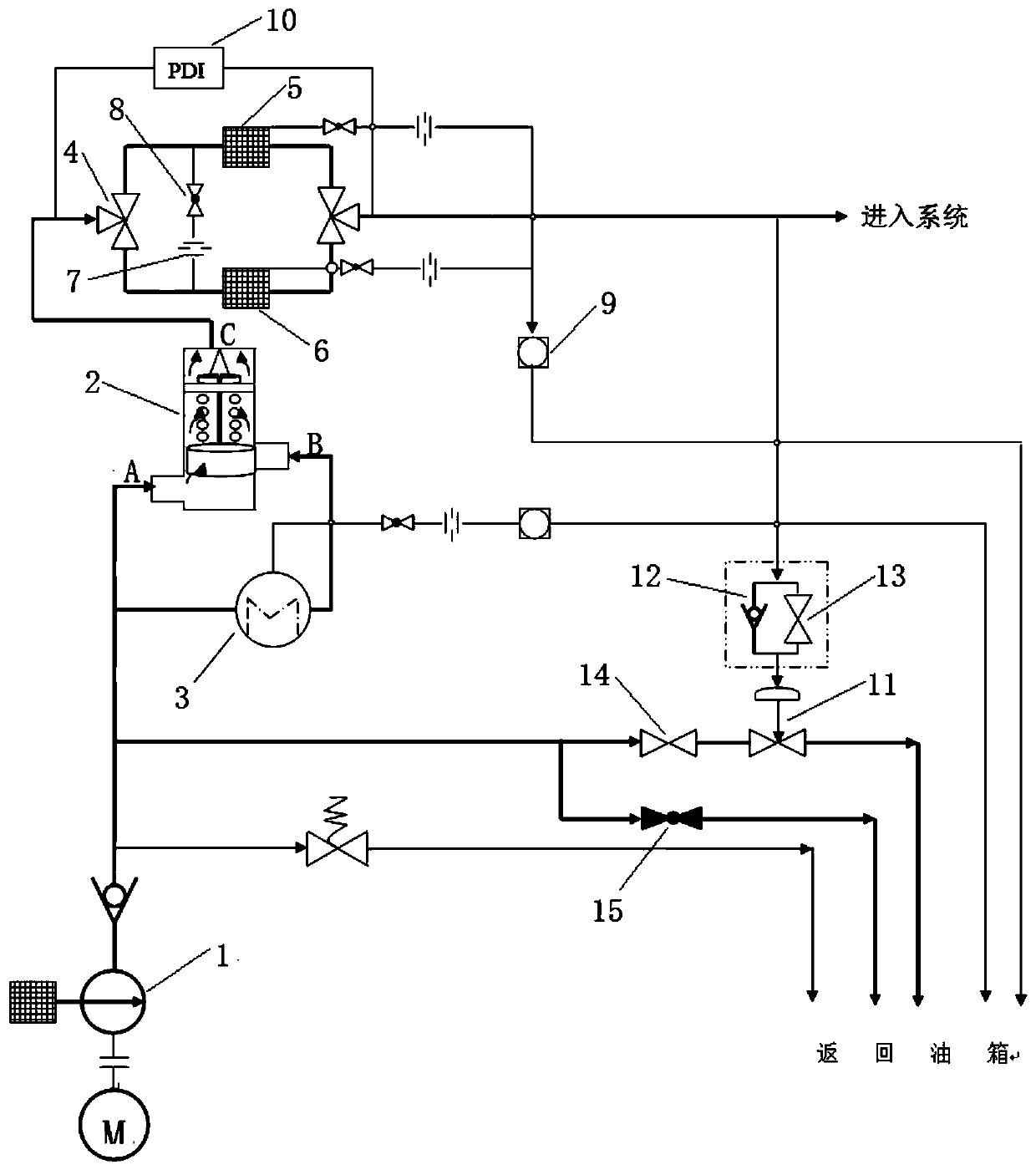

[0029] The embodiment of the present invention provides a constant temperature and pressure lubrication equipment, please refer to figure 1 , the equipment includes:

[0030] An oil pump 1 pumps lubricating oil into the device.

[0031] Specifically, the motor drives the oil pump 1 to rotate, and the oil pump 1 pumps lubricating oil in the oil tank into the device to provide lubricating oil for the operation of the lubricating system.

[0032] The temperature control valve 2, the temperature control valve 2 has a cavity; the first inlet A, the lubricating oil enters the temperature control valve 2 from the first inlet A; the first outlet C, the lubricating oil enters the temperature control valve 2 from the first inlet A The first outlet C flows out of the temperature control valve 2; the second inlet B, the lubricating oil enters the temperature control valve 2 from the second inlet B; the heat sensitive element, the heat sensitive element is arranged on the In the cavity, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com