Preparation method for bismuth telluride based sintered fuel

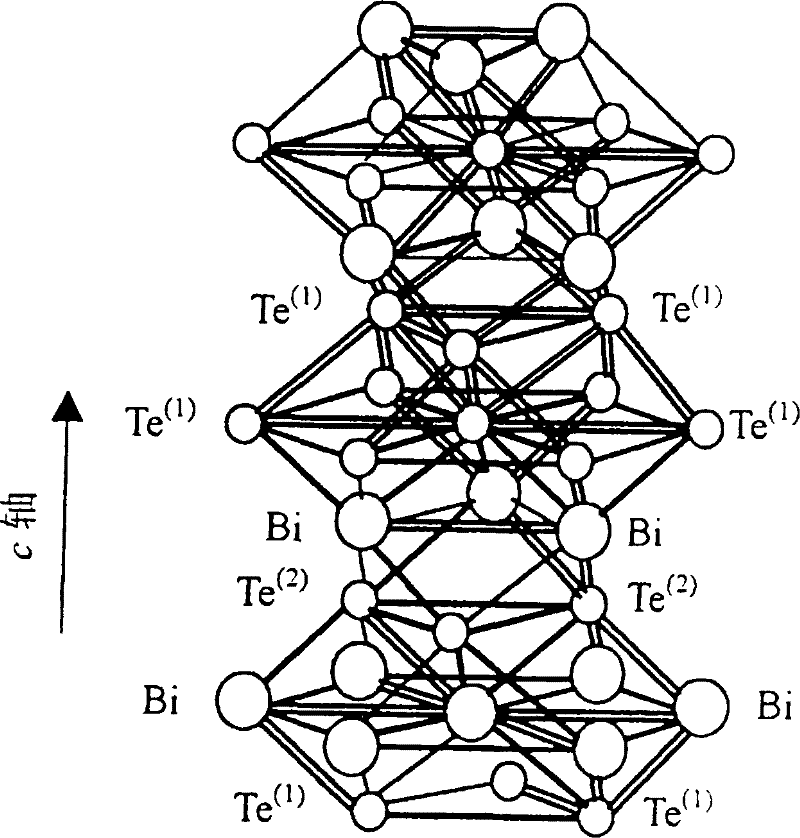

A sintered material, a bismuth telluride-based technology, which is applied to the preparation of bismuth telluride-based materials and the field of preparation of bismuth telluride-based sintered materials, can solve the problems of complex preparation process, impurities and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

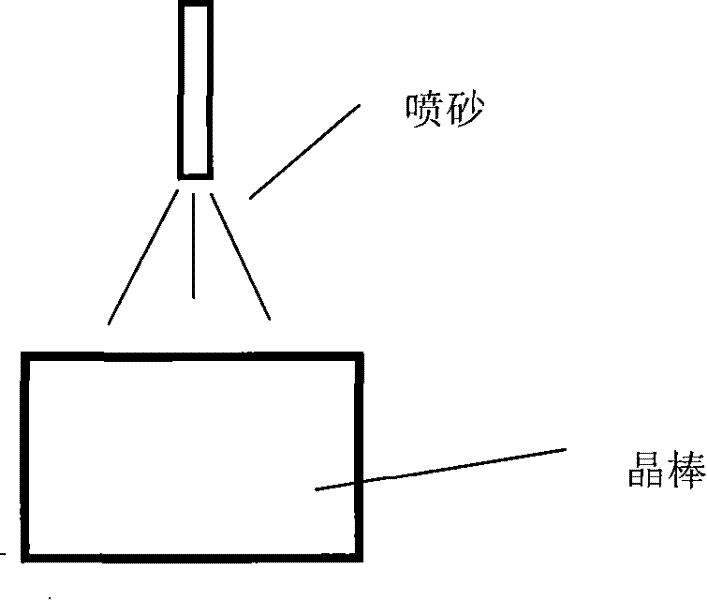

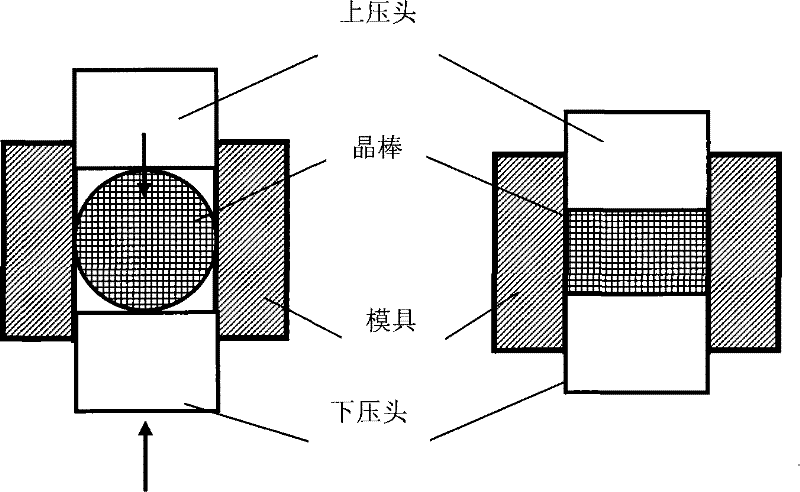

[0022] Use 24% Bi 2 Te 3 +76%Sb 2 Te 3 +3wt%Te P type, 93%Bi 2 Te 3 +7% Bi 2 Se 3 +0.15wt%TeI 4 Use corundum sand, sandblasting to remove oxides and other impurities on the surface, and then ultrasonically clean for 5 minutes. After drying, it is placed in a mold for pre-pressing at a pressure of 20MPa, and then the pre-compressed ingot material is combined with the mold Put them into the spark plasma sintering equipment together, evacuate to 6Pa, energize and press for sintering. The initial current of P-type sintering is 600A, and then increase by 200A every minute until the sintering temperature reaches 390°C and the holding time is 8 minutes to obtain P-type sintered material; the initial current of N-type sintering is 450A, and then increase by 150A every minute. The sintering temperature reaches 450°C, and the temperature is kept for 12 minutes to obtain an N-type sintered material. These sintered materials are used to cut thermoelectric elements of 1.5mm×1.28mm×1.28mm, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com