Regeneration method for di-mix honey de-kalium-sodium resin

A technology of sodium resin and potassium removal, which is applied in the direction of purification using electricity, ion exchange regeneration, chemical instruments and methods, etc., can solve the problems of consuming a lot of manpower and material resources to clean the evaporation tank, affecting heat transfer, and large energy loss. Achieve the effects of saving boiler cleaning costs, improving regeneration efficiency, and saving heat energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

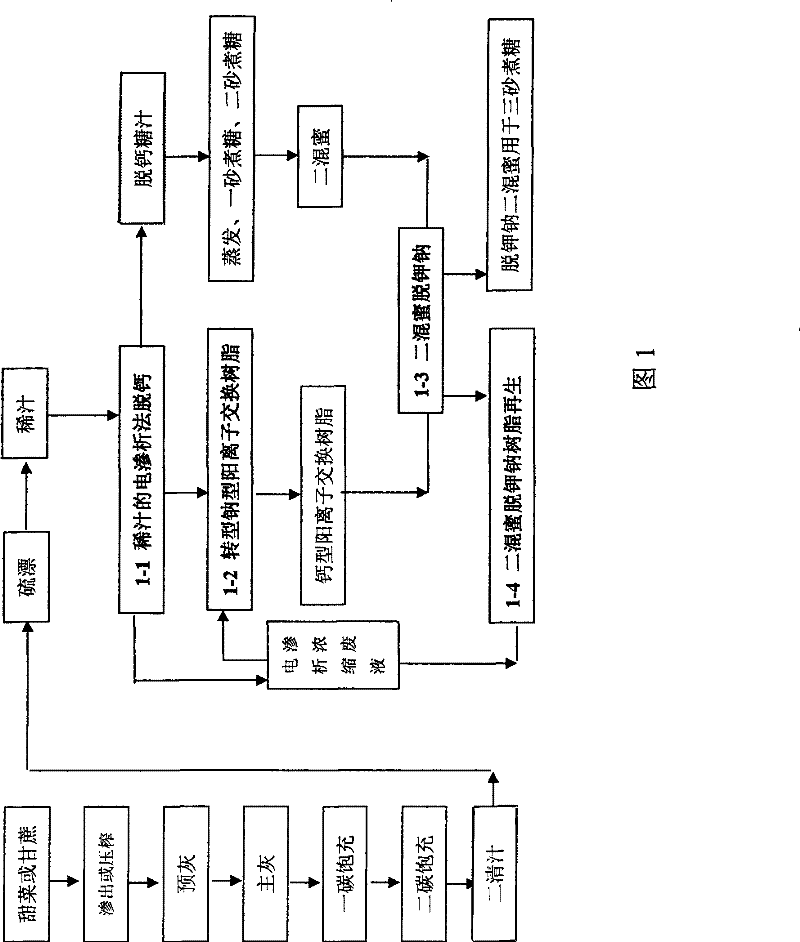

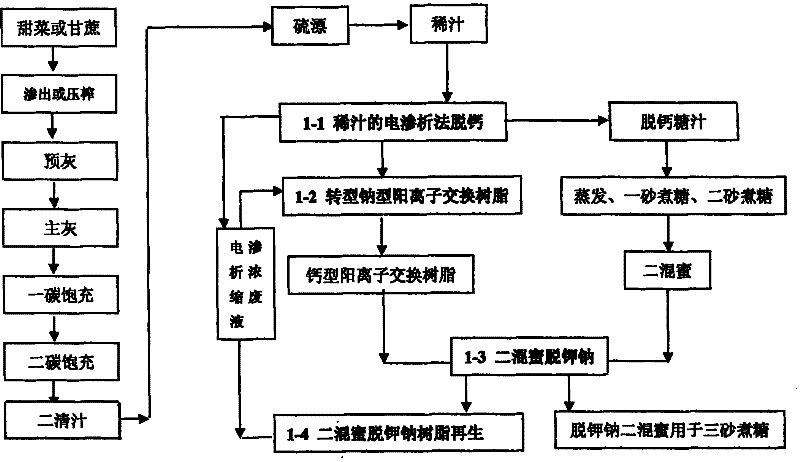

[0022] Such as figure 1 Shown, a kind of regeneration method of two mixed honey depotassium sodium resins, comprises the following steps:

[0023] (1) After the beets are shredded, the purity of beet thin (sugar) juice is greater than 90%, and the Brix is 14°Bx , Ca 2+ The content is 270mg / L. The dilute (sugar) juice was treated by electrodialysis at 45°C with an electrodialyzer ( figure 1 In 1-1) decalcification to obtain Ca 2+ Concentrated electrodialysis waste liquid with a content of 2.0g / L and decalcified beet juice with a calcium ion content of <10mg / L.

[0024] (2) Use 2BV electrodialysis to concentrate the waste liquid at 60 ℃ to commercially available 001×7 type strong acid cation exchange resin (Na + ) for static transformation processing 2h ( figure 1 In 1-2), get Ca 2+ type cation exchange resin and Ca 2+ Beet decalcified dilute (sugar) juice with a content of less than 10 mg / L. Gained beet decalcified thin (sugar) juice is concentrated into a syrup with...

Embodiment 2

[0029] Example 2 is similar to Example 1. The difference is that in the double carbonic acid process, at 30°C, Ca 2+ The sugar beet clear juice with a content of 300mg / L and a Brix of 13°Bx directly enters the electrodialyzer for treatment, with 3BV, Ca 2+ Concentrated electrodialysis waste liquid with a concentration of 4.0g / L was statically regenerated at 80°C for 3 hours or prepared Ca 2+ The type ion exchange resin is used for the removal of potassium and sodium from the mixed honey, and the sugar juice flows out of the electrodialyzer and then enters the sulfur bleaching process for sugar production. After the clear juice is treated by the electrodialyzer, the Ca 2+ The removal rate remained above 90%. When removing potassium and sodium from the two-mixed honey, the brix is 70°Bx, the sugar content is 60%, the temperature is 65°C, and Na + and K + Two mixed honeys with contents of 0.9g / L and 1.8g / L were diluted to 55°Bx with resin washing water, heated to 60°C and ...

Embodiment 3

[0031] (1) After the sugarcane is squeezed, it is pre-ashed, filled with one carbon, filled with two carbons, bleached with sulfur, and filtered to obtain syrup (sugar) juice. The purity is greater than 90%, and the Brix is 12°Bx, Ca 2+ The content is 200mg / L. Dilute (sugar) juice is treated with an electrodialyzer at 25°C to obtain Ca 2+ Concentrated electrodialysis waste liquid and decalcified dilute juice with a content of 3.0g / L.

[0032] (2) with Ca 2+ Content is 3.0g / L 4BV dilute juice electrodialysis method desalination concentration waste liquid, at 90 ℃ to commercially available ZGC151 type strong acid cation exchange resin (Na + ) for 4h static transition processing, get Ca 2+ type cation exchange resin and Ca 2+ Thin sugar cane (sugar) juice with a content of less than 10mg / L. The obtained sugar cane thin (sugar) juice is concentrated into a syrup with a Brix of 65°Bx through four-effect evaporation, and the syrup can be boiled with one granulated sugar and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com