Transmission structure for conveyer belt for screen decorating machine

A technology of screen printing machine and transmission structure, which is applied in the direction of screen printing machine, printing machine, conveyor, etc., and can solve the problems of short pause of the conveyor belt, poor stability, and difficulty in achieving complete synchronization of the cylinder.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

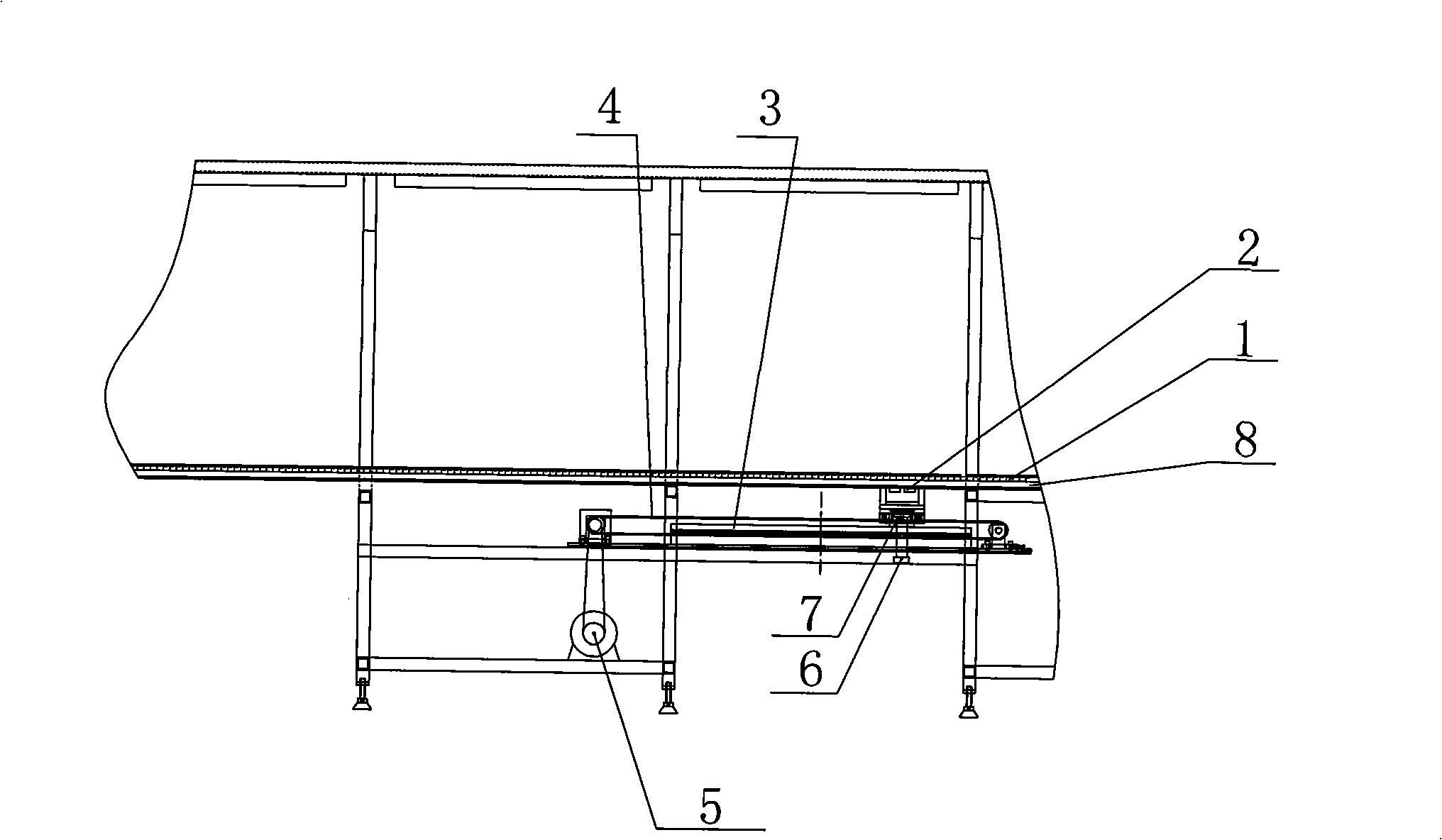

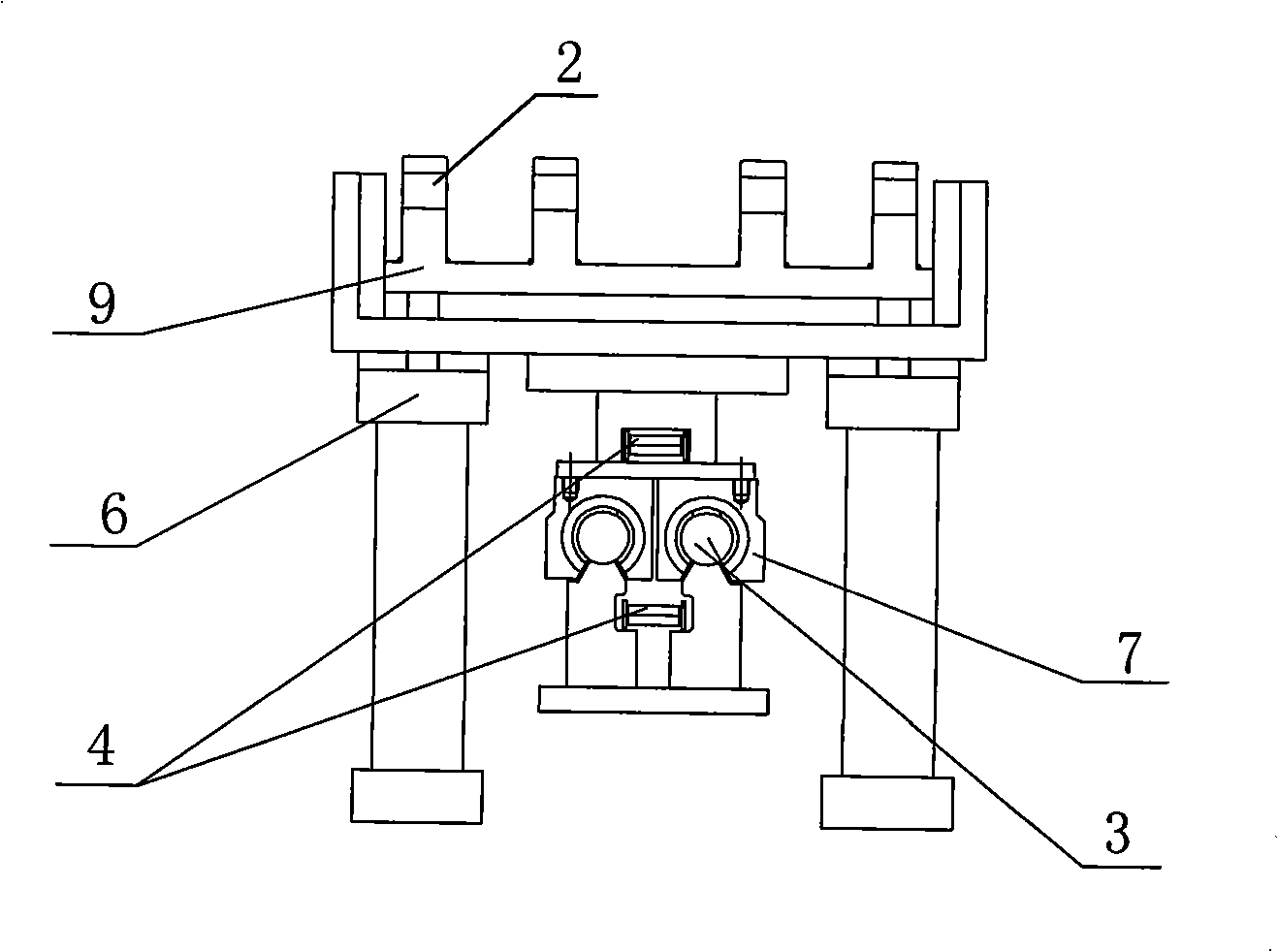

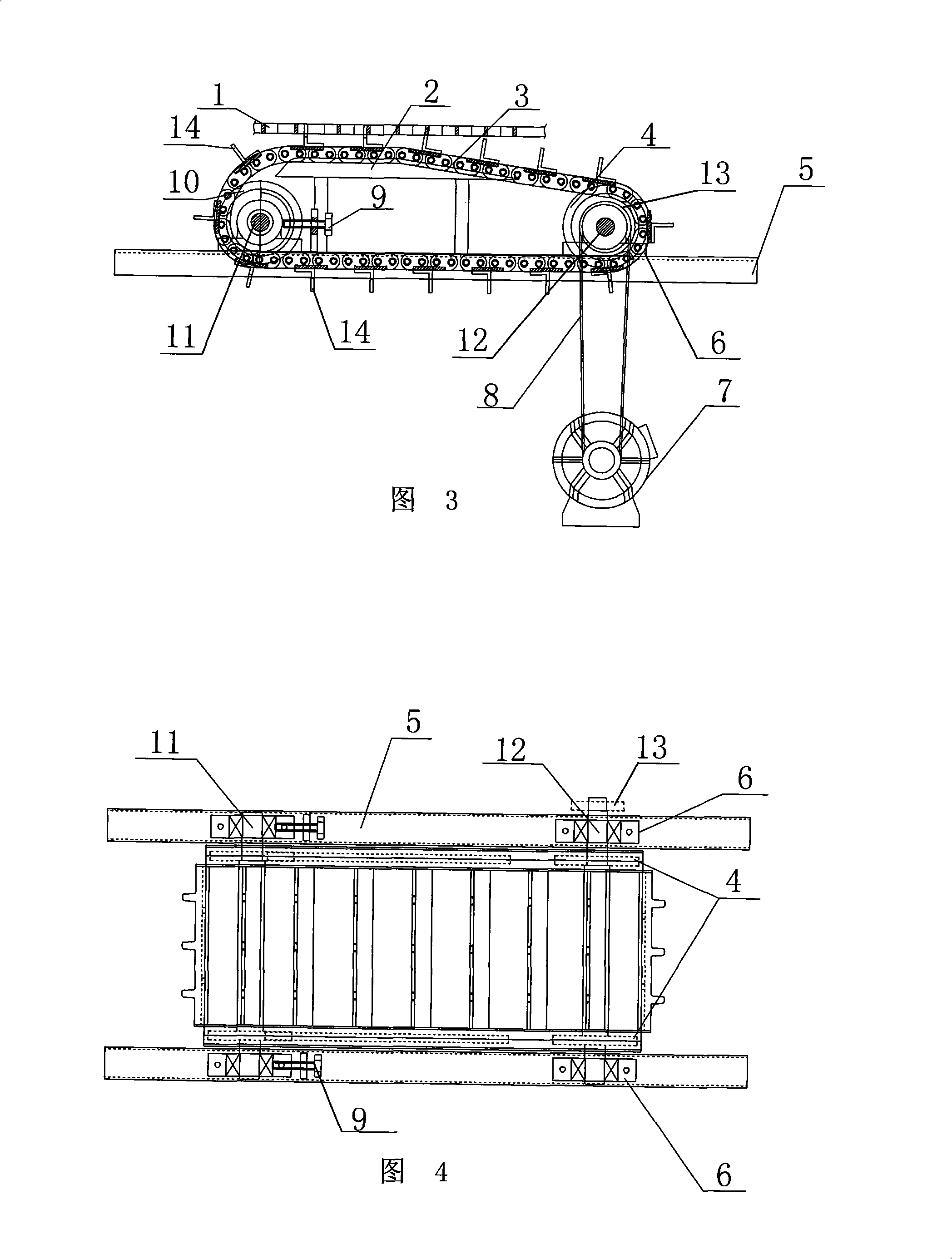

[0011] See Fig. 3, Fig. 4, the present invention comprises conveyer belt 1, conveyer chain 3 and its driving structure, conveyer chain 3 engages with conveyer belt 1 through its externally connected clip 14, and the position of conveyer chain 3 meshes with conveyer belt 1 The two outer parts are respectively obtuse-angled and arc-shaped. This is convenient for the clip 14 to disengage from the conveyor belt 1 after passing the meshing area, and the clip 14 is installed on the adjacent chain links of the conveyor chain 3 respectively; the drive structure includes a motor 7, and the motor 7 is connected to the driving shaft by a chain 8 and a sprocket 13 12. The driving shaft 12 is set with the driving sprocket 4, and the conveying chain 3 is set on the outside of the driving sprocket 4 and the driven sprocket 10. The driving sprocket 4 and the driven sprocket 10 are installed on the bearing housing 6 and the bearing housing 6 respectively. They are respectively installed on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com