Viscosity-increasing precoating film of biaxial tension

A biaxially stretched, biaxially stretched polyester technology, applied in the direction of coating, lamination, layered products, etc., can solve the problem of reducing the yield of film coating, low degree of automation, and affecting the smoothness, clarity and bright color of printed products Degree and other issues, to achieve the effect of filling the gap in the market

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] Embodiment 1: Taking a biaxially oriented polypropylene film (BOPP) tackifying pre-coating film with a width of 1580 mm as an example, it will be described in detail.

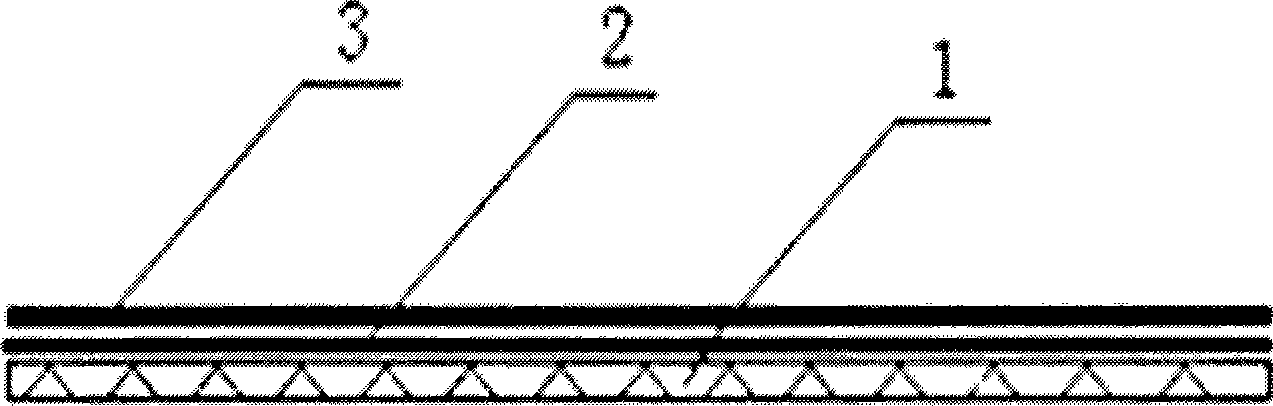

[0052] refer to figure 1 . A biaxially oriented polypropylene film (BOPP) adhesion-increasing pre-coating film is composed of a base material 1, an intermediate layer 2 and a hot-melt adhesive layer 3. The substrate 1, the middle layer 2 and the hot melt adhesive layer 3 have the same width.

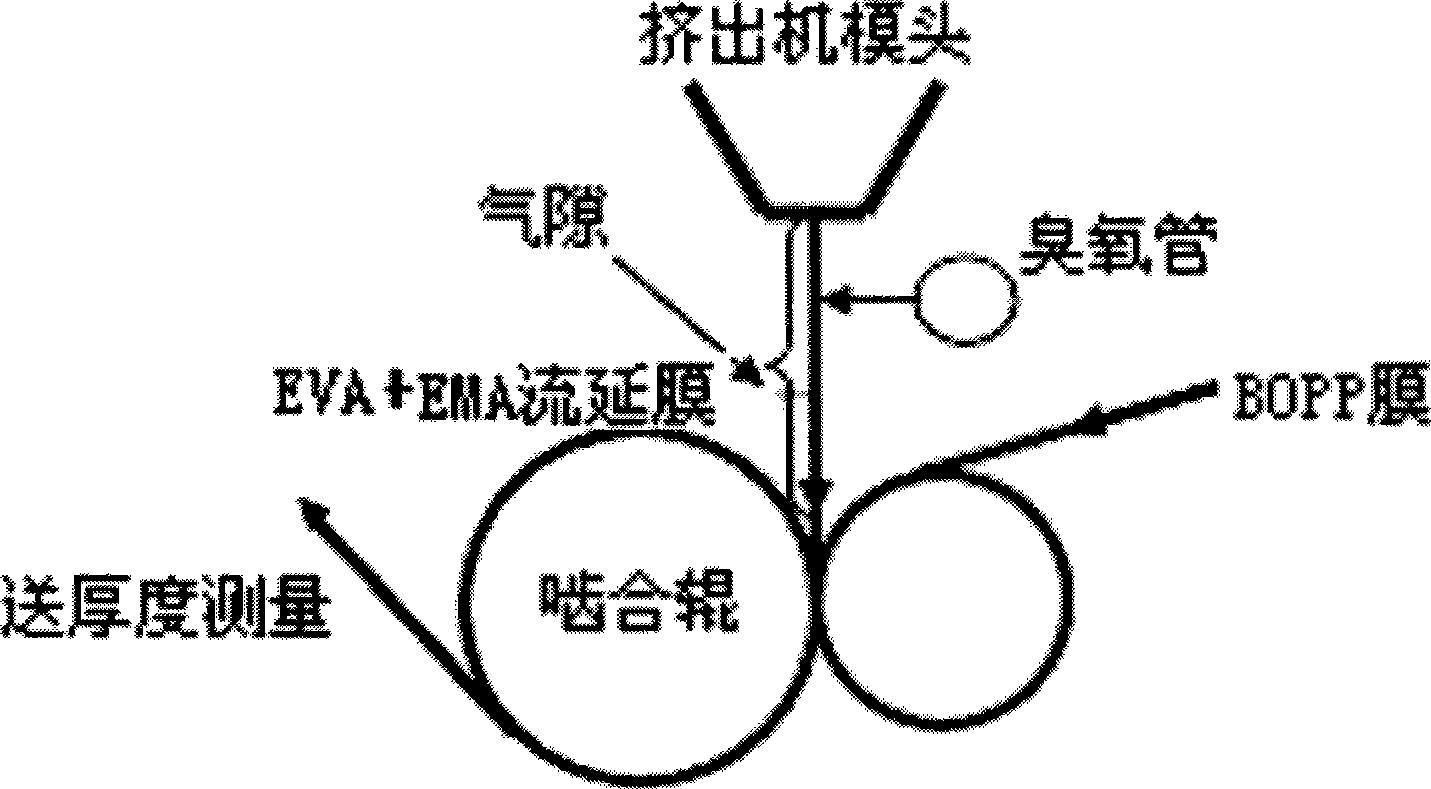

[0053] Biaxially oriented polypropylene film (BOPP) tackifying pre-coating film processing method:

[0054] 1. Preparation of materials for middle layer 2 and hot melt adhesive layer 3

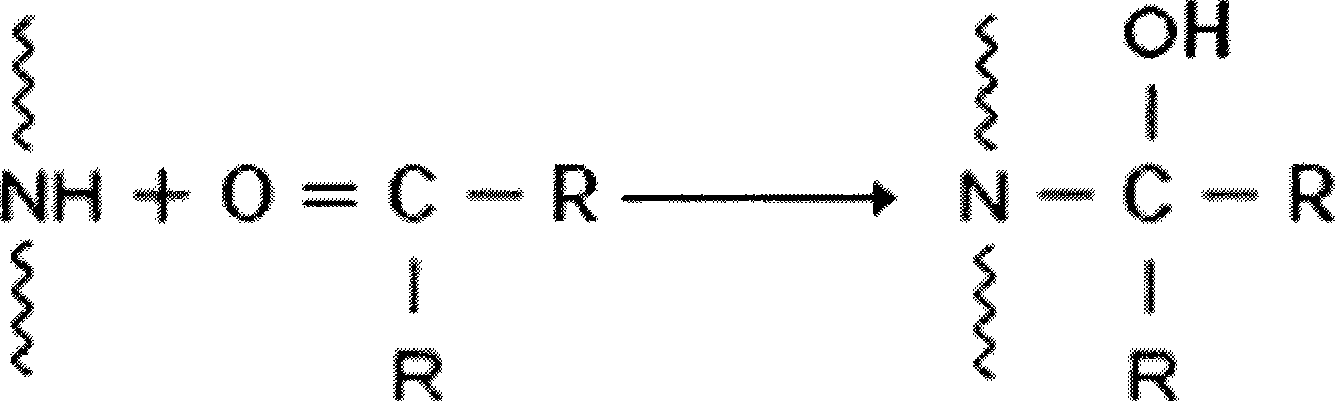

[0055] A, the preparation of middle layer 2 materials: be that the polyethyleneimine (PEI) aqueous solution of 5% solid content is deployed in container and be the polyethyleneimine (PEI) aqueous solution of 0.95% solid content, then add alcohol (analysis Pure), the weight ratio of 0.95% polyethyleneimine (PEI) aqueous solution...

Embodiment 2

[0081] Embodiment 2: Take a biaxially oriented polyester (BOPET) tackifying precoat film with a width of 1795 mm as an example to illustrate

[0082] Embodiment 2 is basically the same as Embodiment 1, the difference is:

[0083]The substrate 1 adopts a biaxially oriented polyester (BOPET) tackifying precoat film with a width of 1795 mm, and the thickness of the substrate 1 is 9 microns;

[0084] After completing the unwinding of step 2, directly carry out the coating intermediate layer 2 of step 4, omitting the corona treatment process of step 3;

[0085] The weight percent of ethylene-vinyl acetate (EVA) and ethylene-methyl acrylate copolymer (EMA) of hot melt adhesive layer 3 is: ethylene-vinyl acetate (EVA) is 61%, ethylene-methyl acrylate copolymer ( EMA) is 39%, and the thickness of the composite hot melt adhesive layer 3 is 25 microns.

[0086] The total thickness of the substrate 1, the middle layer 2, and the hot melt adhesive layer 3 is 34 microns.

[0087] After ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com